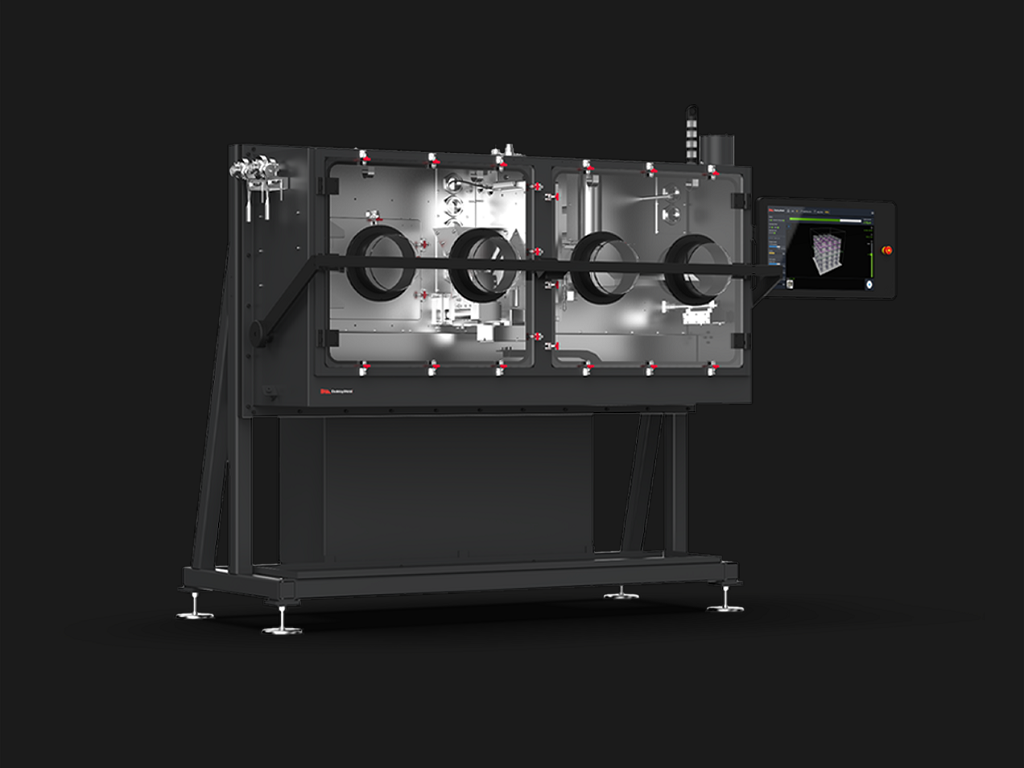

Desktop Metal’s Production System isn’t just a system: it’s a lineup, now including a new 3D printer to bridge the gap between process development and mass production.

The company tipped its hand about the new P-1 earlier last week, as it was mentioned among the solutions shipping in the biggest Desktop Metal announcement of the year. Today, though, the now-public company is formally introducing the P-1.

Desktop Metal Production System Lineup

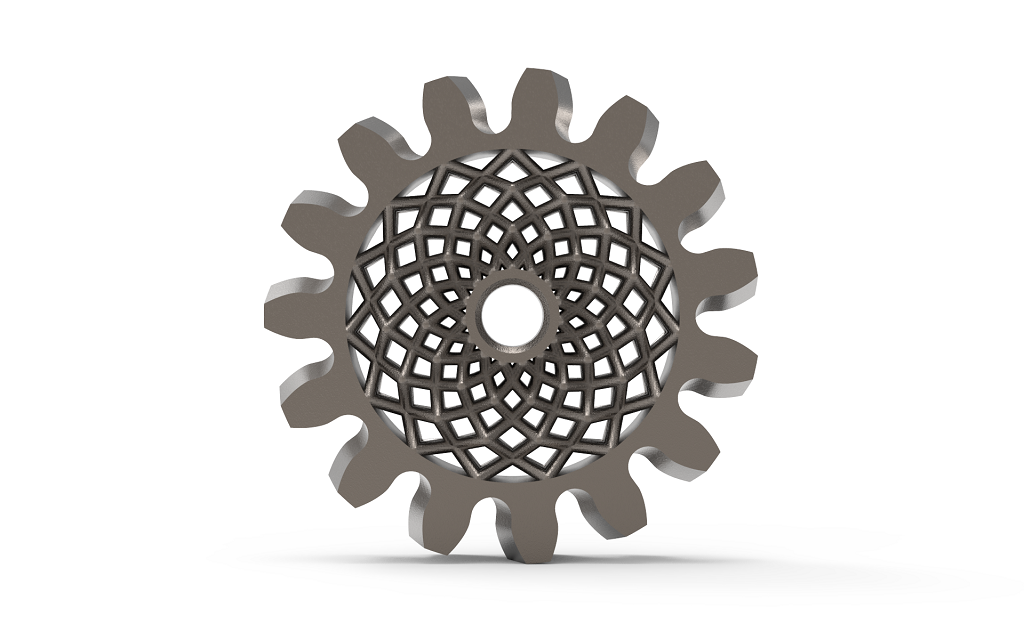

This part of the portfolio is designed to deliver exactly what it says: production. We’ve been taking close looks at the Production System for a bit now; Kerry offers a great rundown here of the technology and specs behind the Desktop Metal Production System. At Formnext 2018, the focus was on making additive manufacturing for production bigger, better, and faster.

But now, we’re going — smaller. To make manufacturing possibilities bigger, better, and faster. The system we’re familiar with is now called the P-50, and stands as the flagship Production System printer. The official announcement explains of the new introduction:

“Designed to serve as a bridge from process development to full-scale mass production of end-use metal parts, the P-1 leverages the same patent-pending Single Pass Jetting (SPJ) technology and core additive manufacturing benefits for companies and research institutions alike at the size and scale of serial production.”

Explaining the P-1 further is Desktop Metal Co-Founder and CEO Ric Fulop:

“We know industrial businesses around the world are eager to begin working with the Production System P-50 and benefit from the fastest, most cost-effective way to manufacture metal parts of all levels of complexity at-scale. Adding the P-1 to our Production System portfolio serves as a key enabler for these companies as they look to develop processes and materials on a smaller scale before ramping up to mass production volumes. Similarly, many businesses and research institutions are also interested in leveraging the economics and quality of SPJ technology for mid-volume serial production, making the P-1 an ideal fit and a great stepping-stone to broad adoption of Desktop Metal’s technology and flagship P-50 printer.”

Bridging Process Development And Mass Production

Additive manufacturing is increasing its presence in the broader industrial world of scale manufacturing. We often see desktop 3D printers installed alongside massive industrial 3D printers at manufacturing facilities. Those systems, though, have very different uses; the desktop systems might validate or prototype designs, but more often they’re used for spare parts, tooling, or jigs and fixtures.

Enter the idea of the P-1: a bridge. Many other companies working toward an industrial future for 3D printing have underscored the importance of prototyping, benchmarking, and scaling to production using the same technology. Think HP and Carbon, for example. Now Desktop Metal customers have this bridge capability as well, using SPJ technology throughout their process.

The P-1 is a smaller format, obviously, than the P-50. The new 3D printer has a 1-liter form factor, which Desktop Metal notes is “designed to print a full layer in less than 3 seconds.” A full build on the P-1 takes less than an hour. Process parameters from a P-1 build can directly transfer to scale production on the P-50 — or the P-1 can itself be used directly for serial production of small parts.

“For many businesses like Ford, the P-1 will serve as a learning lab for processes as they look to scale up to full production,” said Fulop. “Research institutions are also eager to adopt the Production System P-1 to experiment, validate materials, and test a variety of use cases for metal binder jetting with a smaller build box that offers all of the benefits of SPJ technology, including speed, quality, and reliability.”

Production System Shipping

As noted in the NYSE:DM announcement, but more boldly proclaimed today, the Production System P-1 is now shipping globally.

Initial customers are already expecting their orders. Ford Motor Company, for instance, is awaiting its P-1 this month, expanding on their enduring legacy of 3D printing early adoption.

“Ford has been active in 3D printing since 1988 with acquisition of the third commercially available stereolithography (SLA) system; we are very excited to be early adopters of the P-1,” said Cynthia Flanigan, Director, Vehicle Research and Technology, Ford Research and Advanced Engineering. “We expect that this new system will serve as an important tool in the development of our future advanced process and alloy implementation, enabling our researchers to investigate additional production opportunities of metal binder jetting at Ford Motor Company. Our early collaboration with Desktop Metal highlighted the need for a lab scale system that is aligned with the functionality of the production scale system so we can further develop expertise around this process.”

The flagship P-50, for its part, “remains on schedule to begin volume commercial shipments in 2021,” Desktop Metal notes.

Via Desktop Metal