In a major multi-material 3D printing move, Desktop Metal has acquired Aerosint.

Aerosint Multi-Material Additive Manufacturing

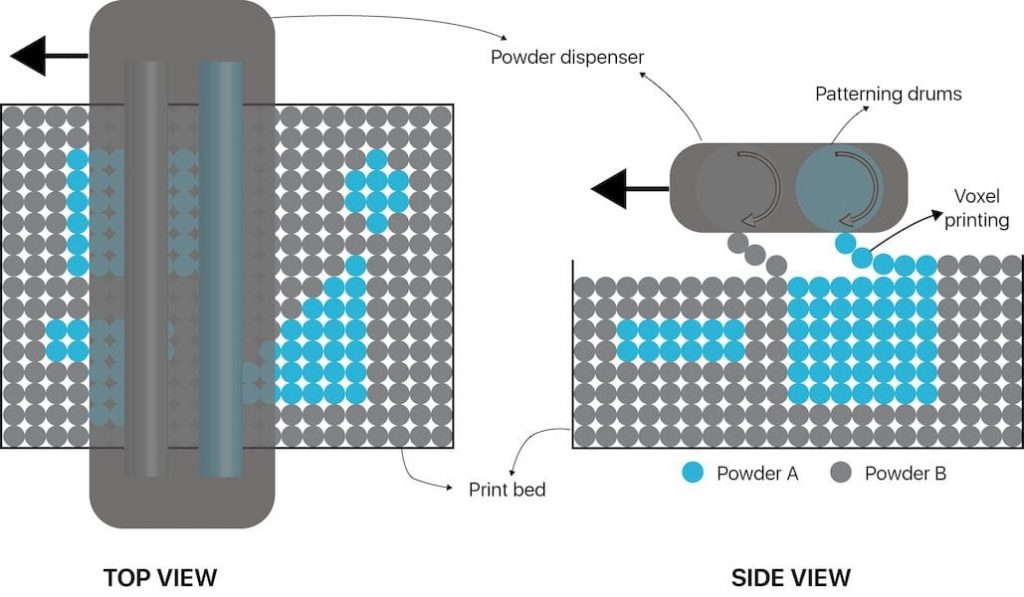

Belgium-based Aerosint has been working on an interesting approach to multi-material powder deposition systems over the last half-decade.

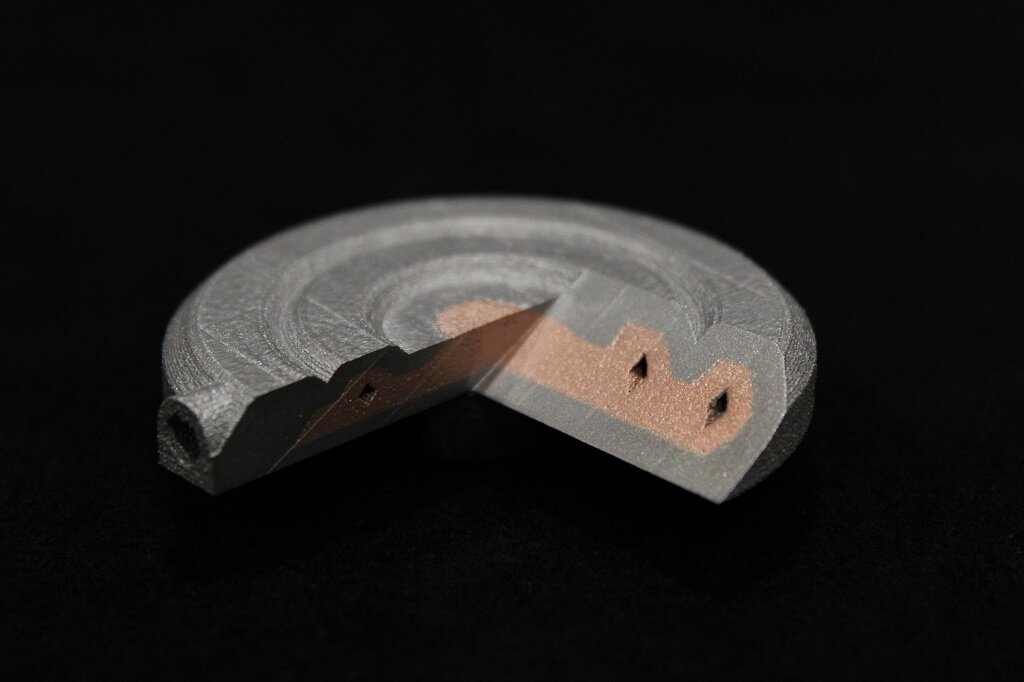

Powder-based additive manufacturing offers great potential for high-throughput production. Until Aerosint, though, material options were limited. Mono-material prints work in a good many uses, but unlocking the potential for more materials opens up the possibility for more benefits across more use cases. Today’s announcement highlights as examples of multi-material 3D printing applications:

- Molds with conformal cooling channels optimized for heat dissipation

- Wear-resistant cutting tools with a hard exterior and ductile interior

- Conductive metal paths within polymer parts for flexible electronics

- Bi-material luxury goods with superior aesthetics

- RF components with different dielectric and conductive properties

The Aerosint process can create these and other builds using a variety of polymer, metal, and ceramic materials.

Aerosint created a process — not a 3D printer. The tech can be integrated “into any powder bed AM process, such as laser powder bed fusion, binder jetting, high-speed sintering or selective laser sintering.” Last year, we saw some of the success the team had in work with Aconity to create multi-material metal 3D prints.

So promising is the technology that it’s drawn great interest from investors — and now from an acquisition.

Aerosint, a Desktop Metal Company

“We have reinvented one part of the machine, the recoating element, so we need to partner with machine manufacturers to integrate into their systems, and sell to their customers. The system can be used in different ways and applications, one of the important applications we have identified is multi-metal. In the beginning, dual metal, combining two metals in one part,” Aerosint Co-Founder and Managing Director Edouard Moens de Hase explained to us previously.

In that conversation, we discussed the integration of the Aerosint recoating system with the Aconity Midi+ system. The Aerosint recoater appeared as an optional upgrade on the Aconity Midi+ pricing for purchasers. By partnering with an established 3D printer manufacturer, Aerosint gained immediate access to not only the specific 3D printer portfolio but that entire customer base.

That strategy continues now — under new ownership.

“At Aerosint, we believe the future of AM is going to be multi-material,” said Moens de Hase. “We are thrilled to partner with Desktop Metal to accelerate the execution of this vision, now with access to its scale, distribution network, and industry-leading AM 2.0 technology portfolio. We look forward to beginning a close collaboration with Desktop Metal while strengthening our ongoing efforts with our existing partners to transform the AM industry and capture new market opportunities.”

As a wholly owned Desktop Metal subsidiary, Aerosint joins the likes of EnvisionTEC in the ever-more-expansive Desktop Metal technology portfolio. Again as with the EnvisionTEC acquisition, the original leadership remains in place for the Aerosint business as founders Edouard Moens de Hase and Matthias Hick serve as, respectively, Managing Director and Innovation Director of the Aerosint business.

The announcement closes on a promising note worth bumping up a bit higher:

“Aerosint multi-material products and services will continue to be widely available to the AM industry with integration into Desktop Metal platforms targeted within the next two years.”

It will certainly be interesting to see exactly where the recoater fits into the Desktop Metal platforms as we get into these next two years.

Desktop Metal Founder and CEO Ric Fulop says today:

“This transaction advances our strategy to own differentiated print technologies that enable an expanding set of AM 2.0 applications at scale. Multi-material printing is the next frontier in AM. Today people print parts, but in the future, people will look to print full products, which may be composed of multiple materials. Industrializing Aerosint’s core technology and related powder processing systems will provide many benefits to the broad adoption of AM solutions. We look forward to partnering with our new colleagues at Aerosint to mature this unique technology and integrate it into upcoming Desktop Metal products over the next several years. We are also excited for Aerosint to independently continue its growth trajectory by offering selective powder deposition solutions and services to third-party manufacturers and customers of powder-based AM systems.”

It’s good to see that not only will Aerosint’s technology continue to be available through existing partners like Aconity, but that the new kinship with Desktop Metal will offer another avenue for the intriguing process to get to market. Aerosint’s creation has long been a promising enigma raising questions like its go-to-market strategy, one of those stories that tends to start with “if this works out, it could be huge!” Well. This could just be the way for this to work out.

As for Desktop Metal, well — Fulop told us upon the announcement of the company’s SPAC move to go public that acquisitions were a major possibility. And as we’ve seen through the course of this year, Desktop Metal has not slowed down since its NYSE debut. A wealth of new businesses, including the all-new Desktop Health, and acquisitions across a variety of 3D printing technology suites and applications have made this portfolio more than formidable.

If there’s a single word today for Desktop Metal, it’s ambitious. Let’s see how the market responds to this latest big move.

Via Desktop Metal and Aerosint