Desktop Health, a line of business within Desktop Metal, announced a new series of dental 3D printers.

The “Einstein” series is comprised of three models, the Einstein, Einstein Pro and Einstein Pro XL.

Unlike most 3D printer announcements, this one is actually a combination of both hardware and materials. It seems that Desktop Health has engineered these devices around the outcome, rather than focusing on the hardware, something most frequently done by 3D printer manufacturers. In other words, the new material, Flexcera Smile Ultra+, was designed for the machine and the machine was designed for Flexcera Smile Ultra+.

Desktop Health said the print results can be exceptional, explaining:

“It has been formulated with the strength of ceramic coupled with long chain chemistry to ensure ideal properties. When used in tandem with the Einstein 3D printers, dental providers can now print same-day smiles, including crowns, bridges, veneers, full and partial dentures.”

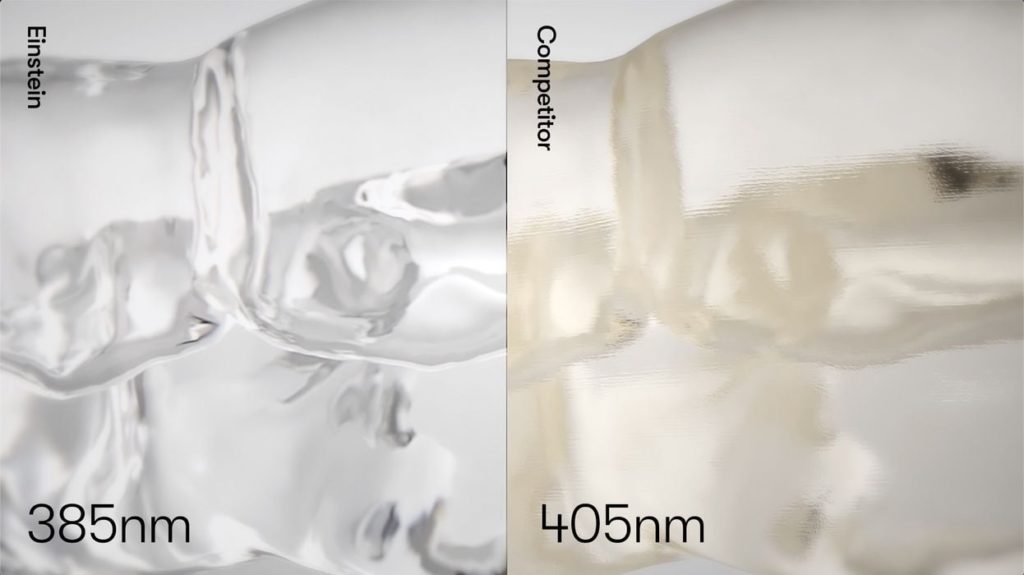

This resin is different from most 3D printer resins in that it reacts to 385nm wavelengths, rather than the more common 405nm wavelengths of most other manufacturers’ resins.

Desktop Health said the hardware-material combo could produce more precise prints, and that seems to be born out given this comparison image:

In addition, the new resin has, according to Desktop Health:

- High fracture resistance, three times more resistant to fracture than select competitive resins

- Moisture resistance to prevent staining or discoloration, two times more resistant than a leading competitive formulation

- An overall natural aesthetic that offers lifelike tooth translucency and a natural- looking smile, providing a perfect blend of comfort, strength and flexibility.

The three different Einstein machines are targeted at different dental environments.

The base Einstein 3D printer is said to be a “chair side” device for prints while a patient waits. The printing system is apparently 50% faster, and takes “only hours”. I’m not sure if that’s short enough for a good patient experience, but it’s getting closer. The tabletop Einstein has a build volume of 190 x 107 x 102 mm, which is actually quite generous, and should accommodate most prints. The machine’s XY resolution is 0.10mm, but with “pixel tuning” can be as small as 0.065mm, using the system’s DLP light engine. The base unit is priced at US$8,999.

The Einstein Pro is visually similar to the base Einstein, albeit slightly taller. Its build volume is slightly larger than the base Einstein at only 180 x 101 x 152 mm, but in a different aspect ratio.

A reason for this difference in build volume is that the Einstein Pro uses a different light engine. Instead of a simple DLP, it uses “Continuous Digital Light Manufacturing”, or “cDLM”. This process eliminates separation forces during printing, meaning there is no delay from lifting on each layer, and the device can effectively print continuously. This model is targeted at small dental labs where quick customer turnaround is required. It’s priced at US$19,999.

The final entry in the Einstein trio is the Einstein Pro XL. This larger freestanding system has a much bigger build volume at 249 x 140 x 165 mm. Unlike the Pro model, the Pro XL uses a DLP system instead of the cDLM system. This is likely because the system is targeted at production operations where throughput is prioritized over raw speed. The Pro XL is listed at US$34,999.

The Einstein models should provide very good results for operators, as they all include sophisticated closed loop monitoring. Printing activities are monitored and corrected in real time, ensuring quality prints.

This is an interesting development in the increasingly crowded dental 3D printing space, but is not unexpected.

Desktop Metal’s recent acquisition of EnvisionTEC hints at what has transpired here. You may notice some rather similar design and technology elements between the new Einstein series and EnvisionTEC’s Perfactory, cDLM and DLP equipment. What we likely have here is a bit of a rebranding, deep materials integration and highly focused market targeting.

I believe this is a very good move by Desktop Metal, as it focuses the technology much more strongly at the application market. The branding may seem to be a superfluous aspect to techies, but in fact this would be seen as a fresh option by those in the dental industry.

In the dental industry, like every other industry using 3D printing technology, the buyers are looking for solutions, not hardware.

Via Desktop Health