A new business is leveraging the vast Desktop Metal / EnvisionTEC 3D printing portfolio for the future of personal healthcare.

Last summer, when Desktop Metal announced that it would be going public, we knew to expect big things. When I asked Co-Founder and CEO Ric Fulop about the company’s motivations, he was clear that expansion was at the forefront:

“It’s something that gives us the ability to recruit talent, and gives us the ability to acquisitive if we need to, more currency to dedicate to our future. It gives us more of an ability to invest in organic growth and supercharge our capabilities.”

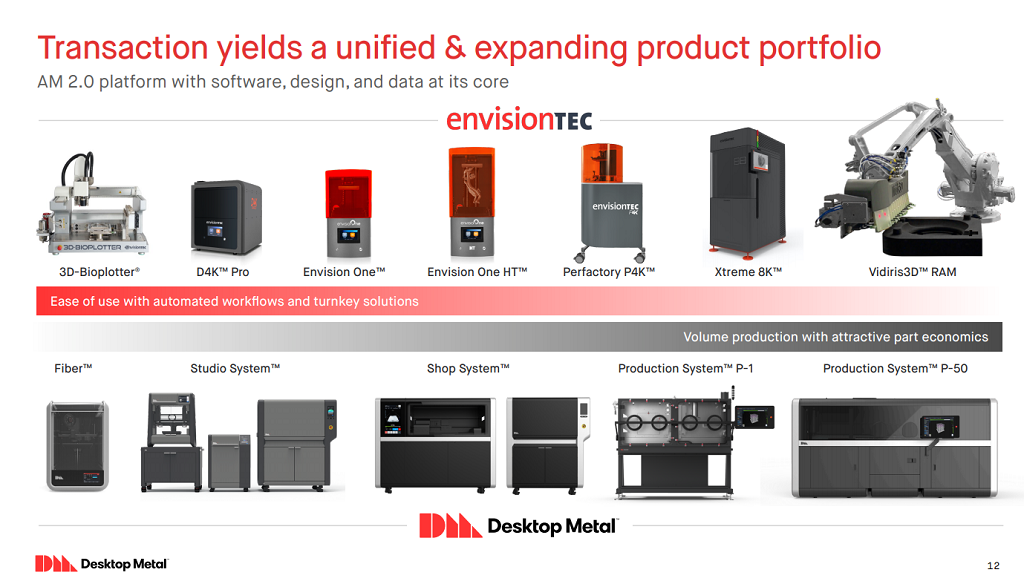

That expansion has been evidenced in spades already. When DM hit the NYSE, expectations — and company valuation — were high. It wasn’t long before Desktop Metal announced EnvisionTEC as its (rather surprising) first acquisition. That deal closed last month, creating a broad-ranging 3D printing technology portfolio.

But what would Desktop Metal do with polymer, bioprinting, and robotic arm additive manufacturing technologies? Other than flex, that is; from binder jetting to carbon fiber to foundry work to 3D printing hearing aids and bio scaffolds, the new portfolio is perhaps intimidating in its scope.

Today, we have the first answer: form an entirely new business. Here’s the “supercharge our capabilities” aspect.

Desktop Health

In an age of industry consolidation, Desktop Metal has today introduced a wholly new, specialized business. California-based Desktop Health is set to focus on, appropriately, health.

The announcement explains that Desktop Health is “a new business line focused on accelerating the growth of additive manufacturing solutions for dental, orthodontic and otolaryngology applications. Furthermore, the combination of new additive manufacturing technologies, including bioprinting, high-speed metal binder jetting, and the use of advanced biocompatible materials across polymers, ceramics and metals, puts Desktop Health in a strong position to develop advanced healthcare applications.”

Once more, that’s:

- Bioprinting

- Metal binder jetting

- Biocompatible polymers

- Biocompatible ceramics

- Biocompatible metals

We’ll bullet point it out because that’s frankly impressive.

EnvisionTEC has long been a leader in 3D printing personalized hearing aids. This, if we’ll recall, was perhaps the first industry to almost completely adopt 3D printing — in a landmark 500-day transition because that’s how much sense the technology makes for this application.

Additive manufacturing has been searching for another use case as significant as hearing aids. They’re a huge part of healthcare 3D printing, and a poster child for impactful mass customization. But, really, every healthcare application should be (ideally) personalized for each patient.

That kind of personalization requires focus. And what better way to focus than with a new, dedicated business? Enter Desktop Health.

The team shared a look at some examples of what Desktop Health may be able to offer in the near- and rather-long-term future:

“Using biocompatible and drug-contact materials, for example, medical devices can now be produced that are tailored for a particular individual. Physicians and medical engineers will be able to customize mass manufacturing options for medical devices — such as dental implants, hearing aids, prostheses, and surgical instruments, often while the patient waits.

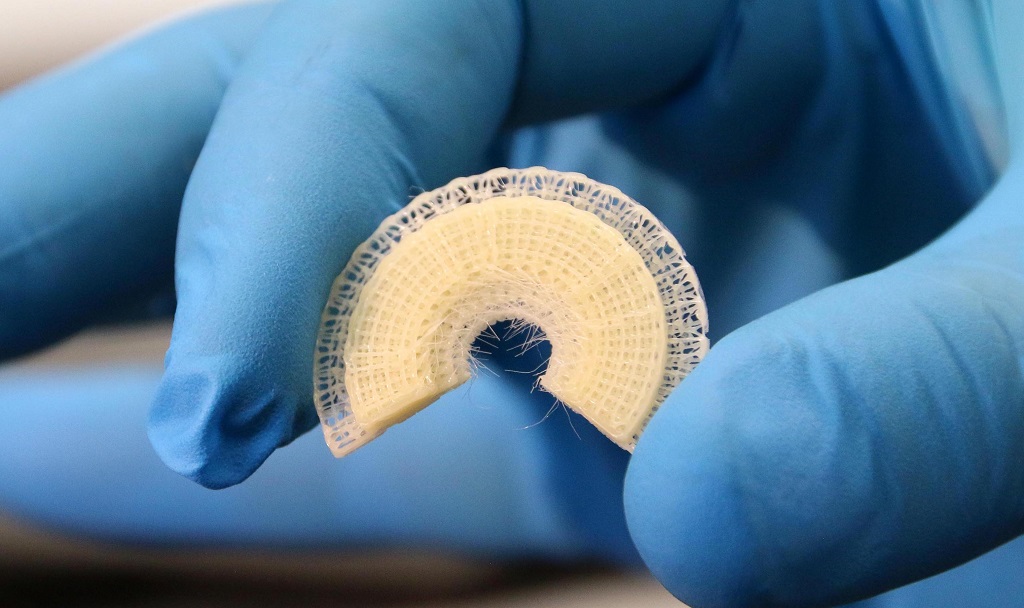

Desktop Health will also bring advances in biofabrication on a bioprinter to allow medical researchers to combine cells, gels, fibers, polymers, ceramics, metals and more into a single scaffolded object that can one day replace a diseased, injured or missing body part, from tissue and bone to organs.

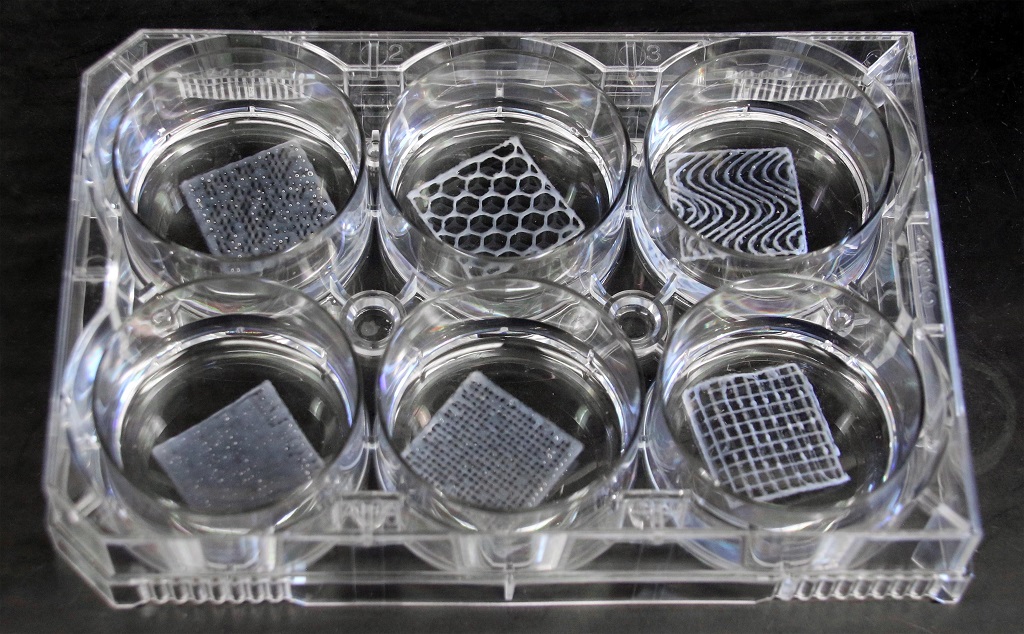

With the 3D Bioplotter, Desktop Health will aid medical engineers in the production of biocompatible parts for medical applications such as bone regeneration, cartilage regeneration, soft tissue fabrication, drug release, and organ printing.”

Applications will target an array of healthcare sectors: dentistry, orthodontics, dermatology, orthopedics, cardiology, plastic surgery, 3D printed regenerative tissues and grafts. Throughout, the focus is on end-use parts production.

Desktop Health Expertise

Naturally, the right technology means little without the right team behind it. Desktop Health is launching today with some solid expertise to guide its first steps.

“We are building a world-class organization using advanced technology in biofabrication to deliver custom implants for every individual across a range of specialties,” said Michael Mazen Jafar, the new President and CEO of Desktop Health.

Jafar joins the Desktop Metal family from a background in “creating and scaling breakthrough healthcare products.” The announcement notes:

“Most recently he served as Chief Commercial Officer of Evolus, a performance beauty company, where he oversaw the launch of its flagship product, Jeuveau. For 16 years, Jafar also led the ophthalmology and medical aesthetics division for Allergan, culminating as VP Marketing, U.S. Medical Aesthetics, and working on several of the company’s marquee brands, including Botox Cosmetic, JUVEDERM Collection and CoolSculpting.”

Along with Jafar are other standouts, like some EnvisionTEC originals and other former members of the Evolus team. Deep EnvisionTEC experience from the original CTO (Alexandr Shkolnik, who “was instrumental in the development of EnvisionTEC’s DLP printing technology”) and Carlos Carvalho (whose work “would eventually lead to the development of the EnvisionTEC 3D-Bioplotter”) ensure complete familiarity with new-to-Desktop Metal technologies.

Jafar’s time at Evolus brought him not just business acumen, but strong enough relationships that Cecilia Gores, VP of Global Marketing, and Kaysar Ridha, VP of Global Product & Design, are now in those roles at Desktop Health. The team’s roots in technology and throughout the medical, pharma, and biotech industries lend strong credibility to the new endeavor.

Along with the team’s ingrained expertise is well-studied technology. This includes, per the new business’ website:

- 1400+ Published Papers

- (publications referencing Bioplotter based on Google Scholar citations 2010 through 2020)

- 260+ Total Pending or Registered Patents

- (including various 3D printing technology and applications as well as biofabrication)

- 190+ Materials in Catalogue

“It’s a true privilege to work with leading technology alongside physicians, surgeons and dentists to advance personal care,” said Jafar. “Our technology is widely used for customized in-office digital dentistry, makes customized metal implants possible, and has enabled exploration of applications such as bone regeneration, cartilage regeneration, and soft tissue biofabrication. We look forward to building on our success and ingenuity as we research extensions of our core technology across cardiology, orthopedics, ophthalmology, dermatology and plastic surgery.”

Via Desktop Health