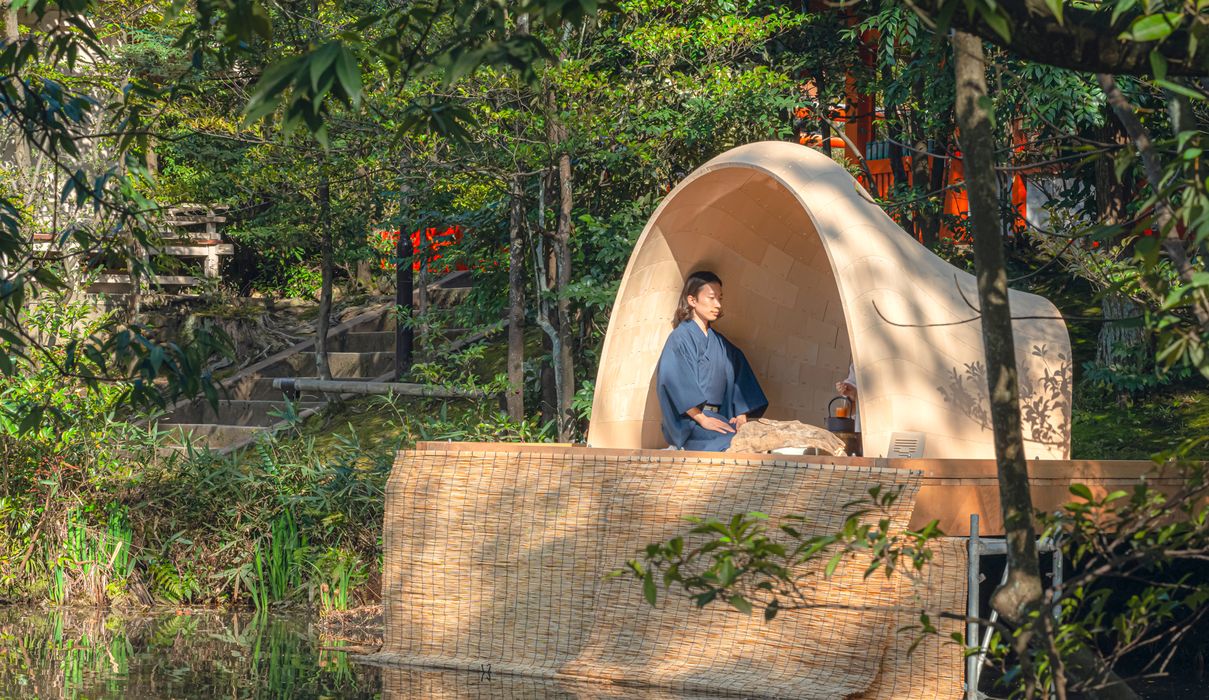

This week’s selection is the TSUGINOTE TEA HOUSE by designers Atsumi Kei and Nicholas Préaud.

The Tea House is an incredible architectural project that used common desktop 3D printing technology to produce a radically different outdoor structure. It is a tea house, but the magic is all in how it was made.

The designers explain (translated):

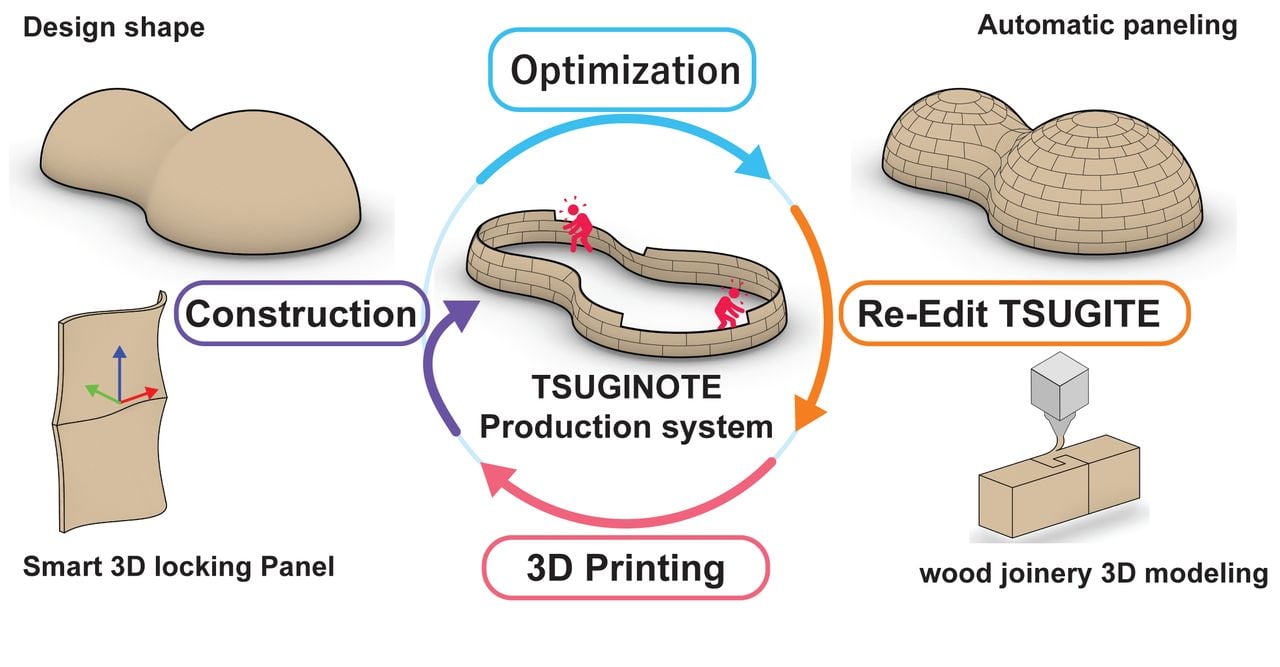

“TSUGINOTE TEA HOUSE has been developed as a prototype that pursues new possibilities in architectural production, such as unlimited design shapes, digitization of architectural production, significant reduction of construction costs, a building system that anyone can assemble and disassemble at any time, and renewable building materials, by combining 3D printing technology and traditional woodworking joint techniques.”

This is the secret to the project. Desktop 3D printers can only produce objects that are small, typically with only 200mm maximum length. How could you make a large structure with them? The designers’ brilliant idea was to combine advanced 3D print technology with traditional woodworking joinery techniques.

The concept turns construction upside down:

“TSUGINOTE has realized a structure system that can easily assemble and disassemble architecture by anyone, not by joining standard parts complexly like modern architecture, but by creating complex parts that take advantage of the characteristics of 3D printing, simplifying part joints, and making three-dimensional joints and self-build construction.”

This is truly the definitive use of additive techniques: letting the technology drive the design.

The project was executed on a standard Flashforge desktop 3D printer, and required about 1000 custom-designed parts. These were printed and assembled into the tea house.

The project team believes it is possible to construct “large-scale structures” using their technique, which apparently incorporates both patented parametric joint designs as well as traditional methods.

Another interesting feature of their technique is that apparently it’s possible for anyone to easily assemble — and disassemble — the structure. This opens up the future possibility of “ordering a building” and assembling it yourself. Perhaps IKEA might be interested in this approach?

I am quite interested in their joinery method, because traditional methods of joining are essential 2D, whereas here they’ve somehow developed a method to do so in 3D. That’s a far more complex problem, and no doubt why the process is patented.

The project team intends on leveraging their technique on further projects. They have in mind a project to develop a “functional housing unit”, which they call “TSUGINOTE MICRO HOME”. They describe its features:

“This autonomous unit, which can be easily constructed and dismantled, incorporates insulation, solar power generation, glass, and water/heating systems, and will contribute to a regenerative future lifestyle.”

The work of this team is impressive and sets a direction for use of 3D print technology in a way few others have done.

Via Atsumi Kei and Nicholas Préaud