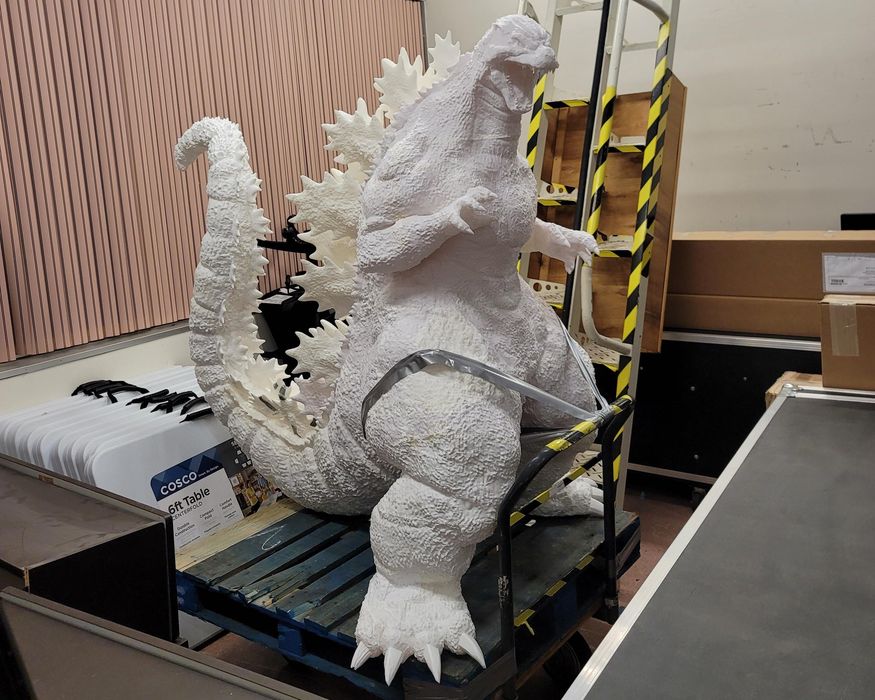

This week’s selection is the Life Size Godzilla Print by Reddit contributor Slayde and team.

Did I say “life size”. Oops, I really mean “human sized”. An actual life size Godzilla would indeed be quite large. Nevertheless, this project is an incredible feat of 3D printing.

Why undertake this incredible project? When asked, Slayde replied:

“I am also still trying to find the answer to this question haha. Was a good learning experience and a ton of fun!

Just thought it would be an awesome project and a learning experience. Printing large scale takes a lot of effort and thinking about how to scale / slice!”

That is most certainly true. Large items such as Godzilla must be carefully split into sections that fit within the build volume of the 3D printers being used. But it’s not that easy: the parts have to be clearly identifiable and their mounting orientation must be known. Often multipart projects like this engineer alignment posts and holes on the parts to ensure things fit together properly.

Evidently this process was challenging for the team:

“We have to figure out better ways to cut up the model and probably invest in a bigger printer haha. As well as make it able to get through doors…”

That is an interesting point, as the images provided seem to show the monster in a typical office cubicle area. What will the boss say when this is discovered?

The team might have considered using LuBan, a 3D modeling utility that is specifically designed to intelligently chop up large 3D models into desired sizes, and it also can automatically insert alignment features.

While Slayde’s team didn’t design the Godzilla (it was scaled up from a normal size), there is plenty of work to do on this project. In fact, Slayde published a chart of accounts for the work:

Here we can see some very interesting statistics.

120 parts were required for the build, which took an astonishing 2700 hours to print. That’s about four months of non-stop 3D printing, but apparently the actual elapsed time took about six months.

The printers used were commonly available desktop machines, including a Creality CR-10.

A large project like this will require a considerable amount of material to complete, and evidently Slayde has been able to purchase 1kg spools at a cost of only US$10 each from SunLu, who apparently often have a “ten spools for US$100” deal on offer. PLA and PLA+ materials were used.

Slayde calculates the total cost of the project at just under US$600, not including electricity, paint and of course, the human labor involved.

That’s not a bad price for a Godzilla the size of a human.

Via Reddit