This week’s selection is Hìtëkw, a 3D Printed Metal Tennis Racket by All Design Lab and Protolabs.

Sports is an area being explored by some using 3D print technology, and it’s thought there are many applications that have yet to be discovered. One interesting experiment was undertaken by the partnership of design studio All Design Labs and manufacturing service Protolabs.

The design studio wished to experiment in the sports area with an unusual design for a beautiful, yet practical tennis racket.

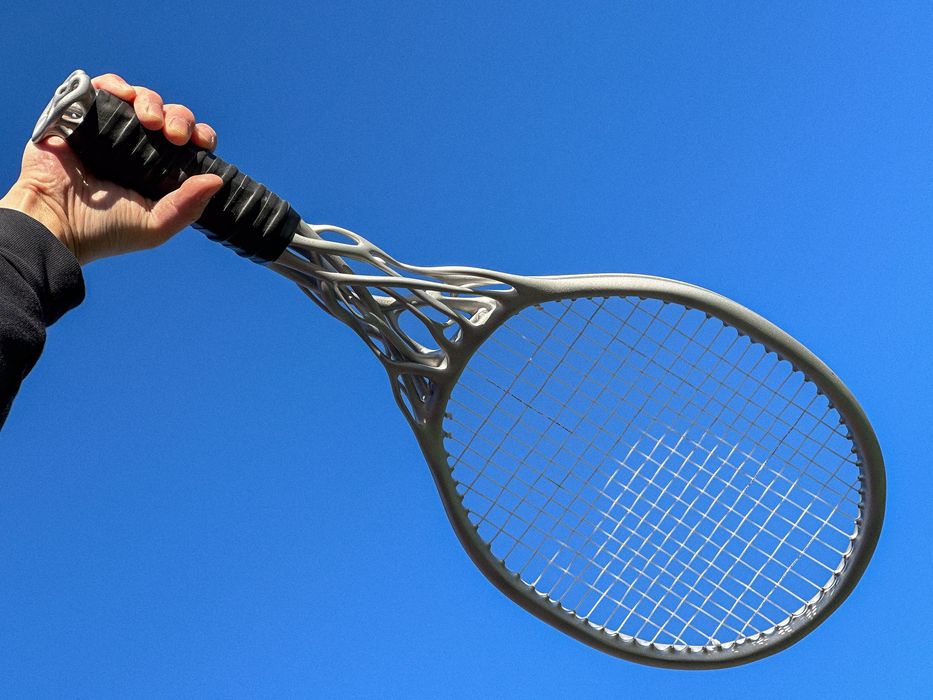

In the design seen at top, it’s evident that the metal structure is complex and reminiscent of the branches of a tree.

That’s where the inspiration for the design’s name, Hìtëkw, came from. The word relates to an indigenous tribe that formerly occupied the northeastern US centuries ago. Those people were very close to the land, and in particular trees. They made many tools from trees, and that spirit is echoed in the Hìtëkw design.

But the complexity of the design is such that it really cannot be produced in any other making technology other than 3D printing, which is why they turned to Protolabs.

It turns out that Protolabs happens to operate several very large metal 3D printers (GE Additive X series), which have a sufficiently large enough build volume to accommodate the full size tennis racket. The racket exceeds 660mm in length, far larger than almost any 3D printer, let alone a metal system.

Protolabs produced the racket using lightweight aluminum, which enabled the part to have a similar weight and feel to traditional tennis rackets.

What happens next? Can you purchase one of these tennis rackets? I suspect not, as it would carry a considerable cost to produce. Nevertheless, All Design Lab intends on showing off the racket at a number of professional tennis events in the future. Hopefully this exposure will inspire athletes and participants to consider how other sports items might take advantage of 3D print technology.

Via Protolabs and All Design Lab