This week’s selection is the Easter Chocolate Egg by industrial designer Marta Ribera Bellmunt.

This is a real, edible chocolate egg produced via 3D printing — but not directly. I find the process of making this egg quite informative, so I thought it would be worthy being Design of the Week.

Bellmunt explains what it’s all about:

“This is the design process of a silicone mold for a 22cm tall Easter chocolate egg, for the Morreig bakery in Barcelona.”

While it certainly looks delicious, let’s learn how it was made.

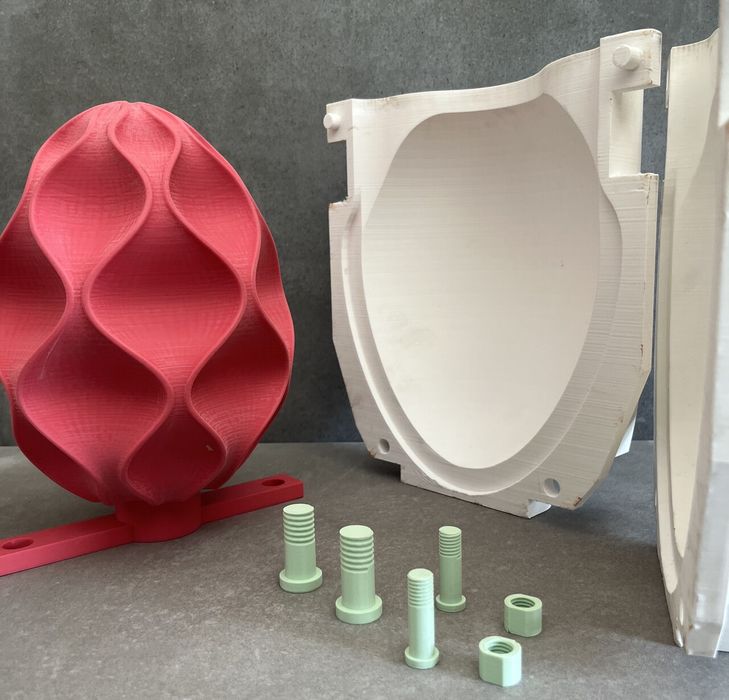

The process began with a digital design of the egg, which was then 3D printed on a BambuLab X1C at full size. This “master” was then used to create a foodsafe silicone mold for casting chocolate.

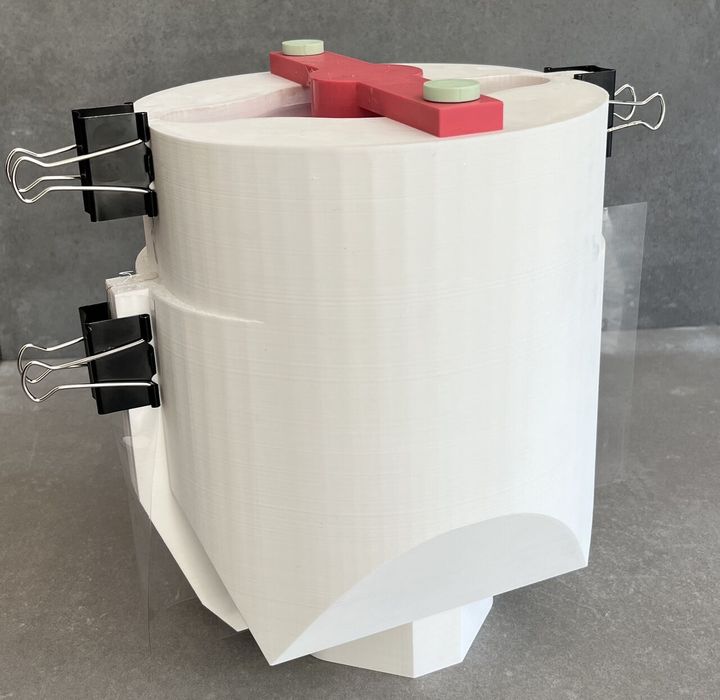

Making a silicone mold requires molding of the original object itself to create a “negative” shape. This was done by 3D printing parts for a specialized egg mold.

The parts were assembled, and the original printed egg was inserted inside. The liquid silicone was poured into the gap and allowed to harden over 24 hours. The mold was disassembled, allowing extraction of the new silicone egg mold.

Into the silicone mold was poured hot liquid chocolate, which was allowed to cool and solidify.

The silicone mold was peeled off the chocolate, revealing the final egg, cast from a 3D printed mold.

It’s a multistep process, but yields excellent results, as you can see — and taste.

The big advantage of this approach is that the silicone mold can be used over and over, which is likely what the Barcelona bakery will be doing. Just wash it off and cast again.

This process is so straightforward that it’s easily possible for anyone with a 3D printer and silicone to attempt. Will you try designing your own chocolate items?

Via LinkedIn