This week’s selection is the Chirping Bird Whistle by Adam Stager.

Stager, holder of a PhD from the University of Delaware in Mechanical Engineering, is a prolific designer of highly unusual 3D printable objects. While his day job seems to be with TRIC robotics, a producer of agricultural robots, (a “Roomba for the field”), he still designs and contributes 3D models to the 3D print community.

His designs range from the complex, like the “Spydar Platform”, a robotic radar device, to the pedestrian “Butter Buddy”. Today we’re focusing on his Chirping Bird Series.

Stager explains the Chirping Bird Whistle:

“Get ready for some chirping! This simple bird whistle was designed for the #MakeItLoud challenge. It produces a consistent high pitched sound when dry, but with some assistance (water) you can make unique chirping melodies. When you get tired of whistling it also doubles as a nice desktop ornament and conversation starter.”

And that’s precisely what it does: you blow into one end and it produces a nice whistle.

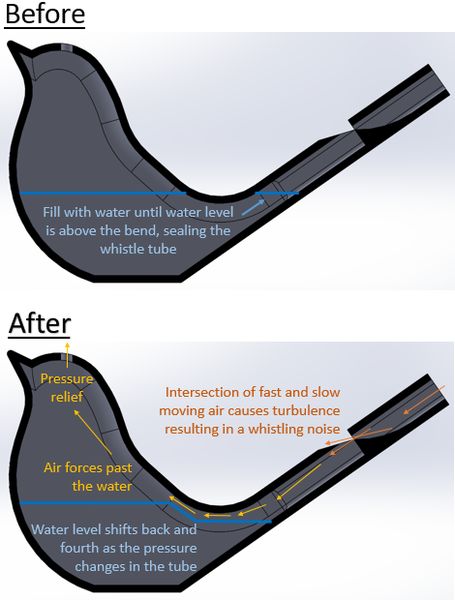

But wait, there’s more: you can make this whistle produce an incredible variety of sounds by adding some water to the interior chamber of the Chirping Bird Whistle. Here’s what it sounds like:

You can vary the sound patterns and tone by playing with the air pressure and water levels.

Amazing, wouldn’t you agree?

I am impressed with this design because it produces notable function while having no moving parts. The results are unexpected and far beyond what you would expect from such a seemingly-straightforward design.

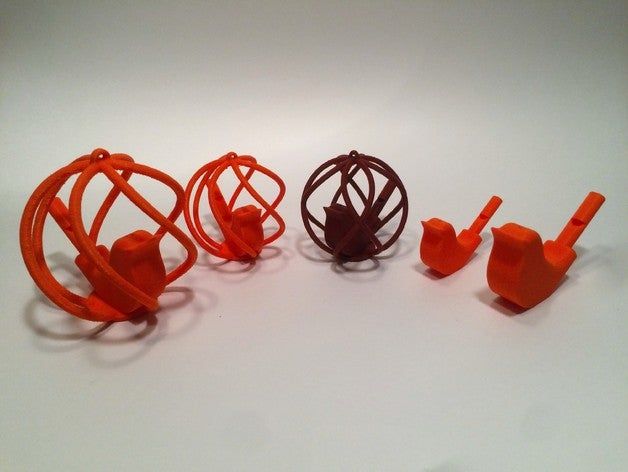

Stager has produced several versions of the Chirping Bird Whistle, beyond the basic design.

One is an educational version that is intended to be 3D printed with transparent material. With the ability to see inside the chamber, it is then possible for students to observe the water movements and understand how the contraption actually works.

Another is a “Holiday” edition that includes a cage around the bird. However, this is pretty challenging to 3D print as there are some rather extreme overhangs and spindly parts.

It’s a fabulous project that every 3D printer operator should take on.

Via Thingiverse