This week’s selection is the outrageous Air Filtration System by software engineer Mike Buss.

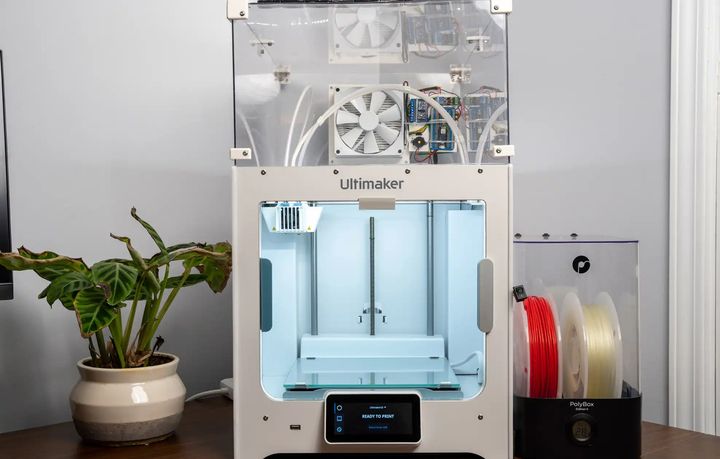

Ohio-based Buss recently obtained a new Ultimaker S3 desktop 3D printer, and as he has recently also obtained a three-month-old infant, he felt the need to make the equipment as safe as possible.

Being aware that 3D printers can generate noxious particle emissions, he set about to build a filtration system that would allow the 3D printer to operate safely in his home. He says:

“I was thinking of projects to work on, and I thought, gee, it would be nice if our 3D printer didn’t kill us.”

3D printing is well-known to emit two kinds of substances. First, there are nanoparticles that blow off when the materials are heated. These float in the air, circulate around and ultimately can be breathed in, where they remain in your lungs. Secondly there are “VOCs”, or volatile organic compounds in the form of gases. These are essentially chemicals that can be toxic if exposed to body tissues. This can certainly add up over the hours of 3D printing that may take place.

Typically these factors vary considerably depending on the type of material, printing process and degree of heat involved in 3D printing. ABS filament is one common material that produces more nanoparticles than most other filaments.

The normal solution for a 3D printer air purifier would be a combination of a sealed chamber, fan, air filtration (activated carbon filter and a HEPA filter) and possibly some ducting.

For those, like Buss, 3D printing only PLA, which doesn’t generate a particularly large amount of emissions, this project might be thought of as overkill. In fact, Buss went WAY over the design line to include as many safety features as possible into the filtration system. This is not just a fan with an air filter.

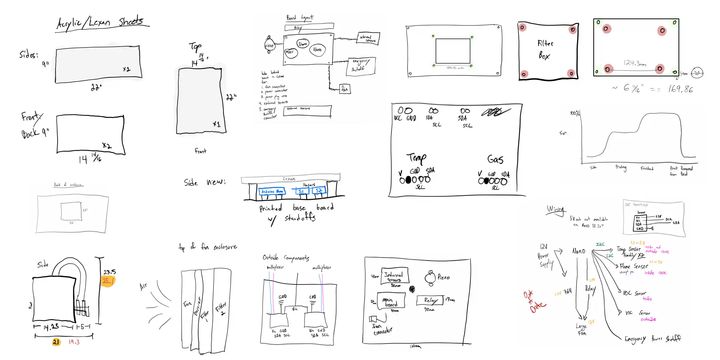

To be sure, Buss did inclue an air filter (with carbon filter) in the final design, but it seems this was one of those hobby projects that just got out of control. He added these features:

- Automatic on/off when 3D printing starts and ends

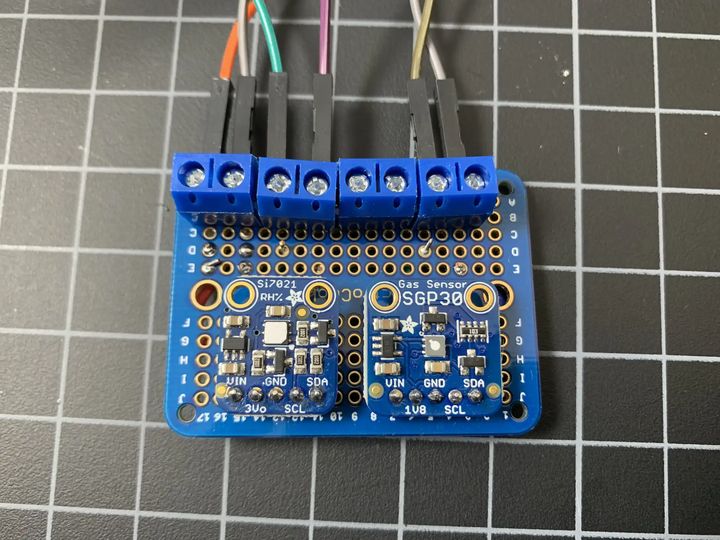

- Volatile organic compound level detector

- Variable fan speed adjusting to current emission levels

- Fire sensor

- Automatic system power down when fire detected

Buss says:

“Eventually, I landed on building a totally ridiculous, completely overkill air filtration system for our 3D printer that probably wasn’t necessary in the first place. And it was lots of fun.”

Buss detailed the entire design and build experience in a long blog post, which I recommend you read through. His solution might not be for everyone due to its complexity. The filtration system includes not only the air purifier with carbon filter system, but also an Arduino controller, external server, integration with Ultimaker’s APIs for status information, added temperature sensors and much more.

There’s no doubt this system will eliminate ultrafine particles in Buss’ home indoor environment, and provide a degree of safety not typically found in home 3D printing setups. But could this be a commercial product in the future?

I’m thinking not, for two reasons. First, a product would have to match customer needs, and this design is likely way beyond what most people would require. Secondly, this design is specifically for the Ultimaker 3D printer, and thus would have to be redesigned for other systems, creating a lot of effort.

If you’ve got interest in making your own 3D printing air purifier, take a read through Buss’ story.

Via Mike Buss