This week’s selection is the 3D Printed Flying Car by Alan Zhang.

Zhang is an engineering student at UC Berkeley, specializing in — you guessed it — UAVs, eVTOLs, and similar airborne vehicles.

For those unfamiliar, an “eVTOL” is an Electric Vertical Takeoff and Landing vehicle. It’s quite similar to a consumer drone in structure, but scaled up immensely. It’s large enough to carry a single person on board during flight.

There are a very few commercial ventures attempting development of personal eVTOLs, but none have yet “taken off”, in business terms. It’s a very challenging project, as you can imagine. This makes Zhang’s work even more impressive: he seems to be half-way to take off, and he’s literally a student building this aircraft in his garage.

Zhang posted a video on the project, which is more or less a stream of experience from design to build, with few technical details revealed.

However, we can see in the video that Zhang’s design involves a number of custom 3D printed connectors holding together a network of lightweight and strong carbon fiber tubes.

Also required for the project were electronics, batteries, wiring, powerful electric motors and propellers. It’s a significant design and perhaps the most complex 3D printing project we’ve featured as Design of the Week.

We don’t know much about the process and design, as Zhang did not include that information in the video. However, by observation we can infer a few things.

One is that he’s used a combination of Bambu Lab, Prusa Research, Markforged and possibly even a Fortus 3D printer for production of the numerous custom parts. The use of the Markforged machine suggests that at least some of the parts would be made with continuous carbon fiber for strength. That would no doubt be a requirement for some of the flight-critical parts in the unnamed eVTOL.

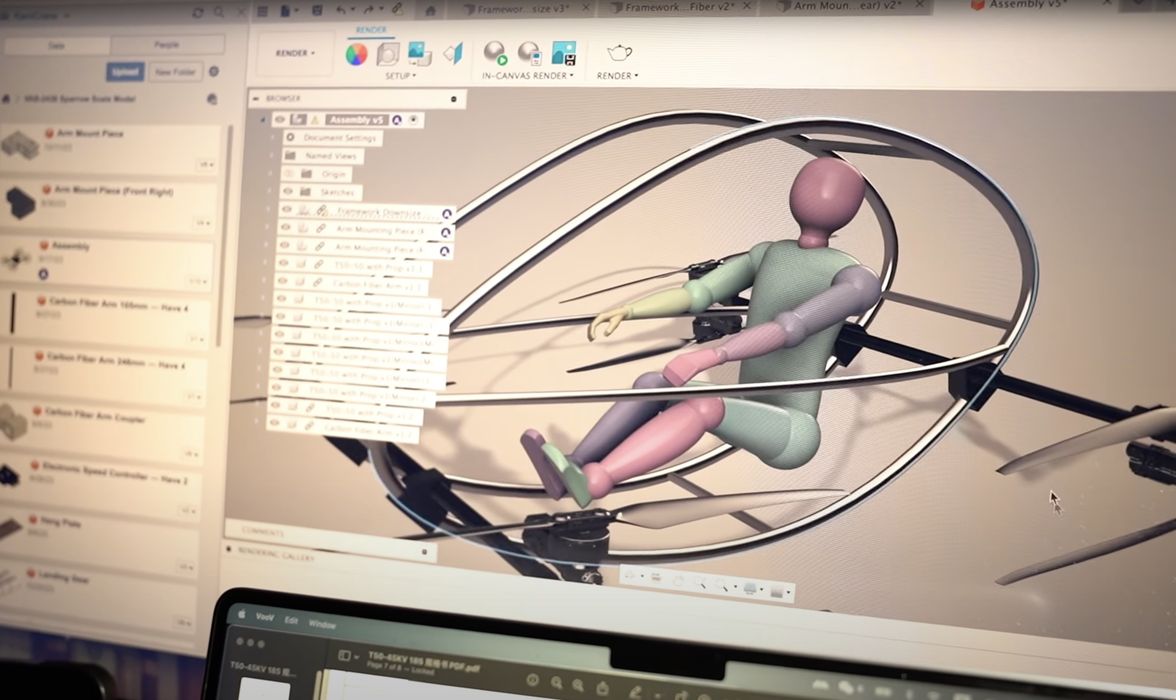

Design software appears to be Autodesk Fusion 360, which is a very popular tool for design of industrial parts. It would be ideal for this project, as Autodesk offers free licenses for personal use.

We don’t know the other materials used in the system, but almost certainly PLA is not one of them due to its brittleness. I suspect ASA would be a suitable material for many of the components as it has a high softening temperature, has some “give” on impacts and is resistant to outdoor UV-laden sunlight.

While the build is very impressive, this seems to be “part one” of the project. Towards the end Zhang explains that he’s still refining the design and requires more hardware to get the device airborne.

That’s expected to occur sometime this summer, and I will certainly be watching when that happens.

Via YouTube