Despite all of the advances in additive manufacturing over the past decade, the 33-year-old STL format remains the most widely used format. While this legacy format is adequate for simple, single material, single color applications, today’s additive manufacturing engineers need a more robust format to improve the quality, precision and repeatability for industrial use across an ever widening range of materials, colors, surface textures, composites, and more complex assemblies.

That’s where AMF comes in. It’s been 7 years since the International Standards Organization (ISO) and the ASTM standards organization published the Standard Specification for Additive Manufacturing File Format (AMF) v1.0. Since then, two updates to this standard have been published. Version 1.2 was published May 2020 (ISO/ASTM 52915:20). This specification was developed to address the need for an advanced 3D file format optimized for modern additive manufacturing applications.

While many people have heard of AMF, very few have a good understanding of the many useful features this format provides.

Here are seven of its many attributes that can help AM professionals improve accuracy, quality and security to their AM projects, while expanding the range of parts and/or assemblies that can be produced:

Superior Accuracy

AMF files are defined in 64 bit accuracy math vs 32 bit for STL files. The improvement of accuracy may not be significant for parts the size of a toaster, but for tiny electronics components, medical stents, lattices, printed pharmaceuticals, bio-printing of high precision micro-prints and other very high precision parts, this a potential game changer.

Integrated support for precisely aligned assemblies

AMF “constellations” can include multiple discreet parts and/or sub-assemblies in a single file. All are precisely oriented and aligned in the proper configuration, with specified distances between components. This enables more precise printing of complex or multi-material integrated assemblies.

Support for multiple materials, including composites and gradient composites in a single file

Materials are definable at object level or at component level. This enables the printing of complex, multi-material parts (and assemblies when combined in a “constellation”).

Support for multiple colors, including gradient transitions

AMF supports over 16 million 32 bit RGBa colors and 256 alpha levels. This is a major improvement over STL’s support of 15 bit color and 5 bits per channel. As color is not a part of the STL specification, there are two mutually exclusive ad-hoc specifications for color in STL files, making it difficult to ensure implementing specified colors. With AMF, any number of colors can be applied to assemblies, individual objects, components or even at individual facet level. Color gradients can also be implemented. AMF also supports industry standard color profiles, providing more accurate implementation of each projects’ color specifications.

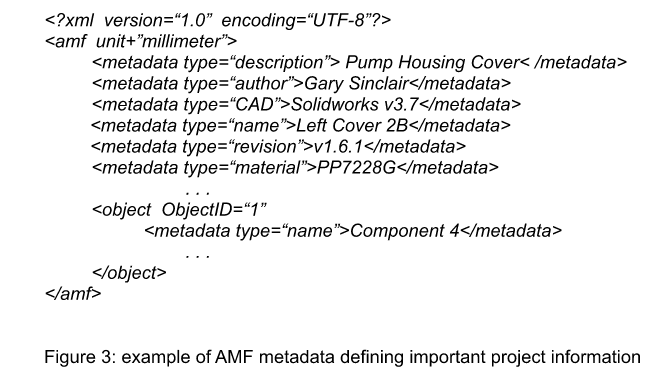

Support for extensible, integrated meta data (XML)

The AMF file is defined using XML v1.0, so it is easy to read and add custom meta data. This is quite useful in passing resolution, IP references, version history and other important file information reliably through the entire AM software work flow. This provides for improved quality control and legal protection. Because it is extensible, new meta data and new functions can be added in the future as AM technology evolves. For example, if the file design is optimized for a specific printing method and layer height, the design engineer could add this information as custom meta data to the AMF file. Legacy AMF readers will be able to read new AMF files containing new meta data. They will simply ignore any new meta data strings and read the AMF file without any problem.

Standardized compression method (zip)

The AMF specification allows for the inclusion of related files in the zip file. Important design, IP, cybersecurity and manufacturing documentation can be included. For example, copyrights and licensing disclosures by component could be listed. Print orientation and other printing system instructions could be added, along with cyber-security keys in the compressed zip file for use in a factory’s PLM system.

AMF is backward compatible with STL

It is supported by over 35 AM software applications, including CAD, modeling and slicing software. This takes the pain out of transitioning to AMF.

AMF is the safe and prudent AM format choice for the long term. It is the only international standards based file format specified for additive manufacturing. Its specification is published and maintained by a partnership of ISO and ASTM, the two largest standards organizations in the world with formal committees established specifically for creating and maintaining open AM standards. It is an integral part of the growing number of ISO and ASTM standards for AM, and is the only format specified in these standards other than the legacy STL format.

While other formats such as .OBJ and 3MF may exhibit some of the capabilities of AMF, they are not open standards. Unlike AMF, they lack the security of endorsement and support from a large number of standards groups and government agencies in dozens of countries.

AMF is the “safe bet” format for additive manufacturers in government regulated industries. For example, AMF is the only file format recommended by name in FDA published guidelines on additive manufacturing of medical devices.

In summary, the AMF format delivers the accuracy, functionality, and extensibility needed to deliver better quality products for industry as additive manufacturing technology continues to evolve.

For more information on AMF, here are a list of online sources:

(note: the AMF specification is included in the following publication: ISO / ASTM52915 – 20: “Specification for additive manufacturing file format (AMF) Version 1.2”)

- ASTM: www.astm.org

- ISO: www.iso.org

- FDA: fda.gov: “Technical Considerations for Additive Manufactured Medical Devices.”

- America Makes: www.americamakes.us

- Avante Technology, llc: bobz@avante-technology.com