Polymaker announced a new series of high speed 3D print materials called “PolySonic”.

This is Polymaker’s official response to the wave of high speed 3D printers that have recently emerged. The problem is that while the hardware can be acquired, there’s a shortage of materials that can successfully 3D print at the highest speeds.

In fact, there is massive confusion about what a “high speed” material really is, as we discussed earlier this week.

In the midst of that confusion Polymaker has arrived with a very well-thought out solution they call “PolySonic”.

It’s a line of “high speed” 3D printer filaments. However, unlike all the other providers of “high speed” filament, Polymaker explained exactly how their products achieve higher speeds.

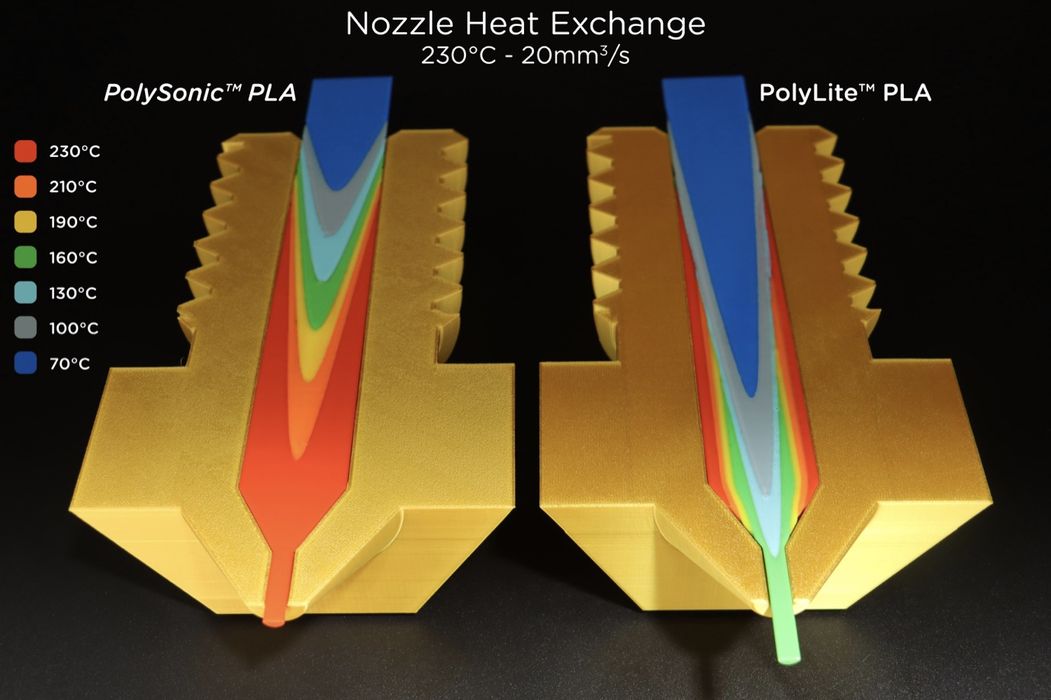

First, why does one need “high speed” filament? It’s because at higher speeds the thermoplastic passes through the hot end more rapidly, meaning it has less time to soften. This requires ever higher hot end temperatures, but there’s a limit to speed even then.

Enter “high speed” filaments, which are designed to soften more quickly, and thus be more compatible with higher speed printing.

What has Polymaker done with their new product, PolySonic? They’ve broken down the high speed problem into three aspects:

- Maximizing flow rate: making the material able to soften more quickly to increase the volume of extrusion

- Maintaining cooling rates: ensuring the material cools very quickly in spite of faster softening rates, to maintain sharpness of prints

- Maintaining print strength: ensuring the resulting prints have close to the same part strength as those made with normal print speeds

As you can see, it’s the combination of these factors that is important. For example, it makes no sense to perform high speed 3D printing and make parts that aren’t very strong. It makes no sense to print at high speed and have sloppy quality. Polymaker has correctly identified what makes for a successful high speed material.

After reading their explanation, it now occurs to me that I have NOT seen similar explanations on other filaments labelled “high speed”. What would be the part strength of those materials? Or the print quality? Who knows? Were these aspects even taken into account?

I asked Polymaker’s Luke Taylor if the company had an official definition of what they consider “high speed” filaments, and this is his explanation, along with some very revealing information about how high speed is being portrayed in the market:

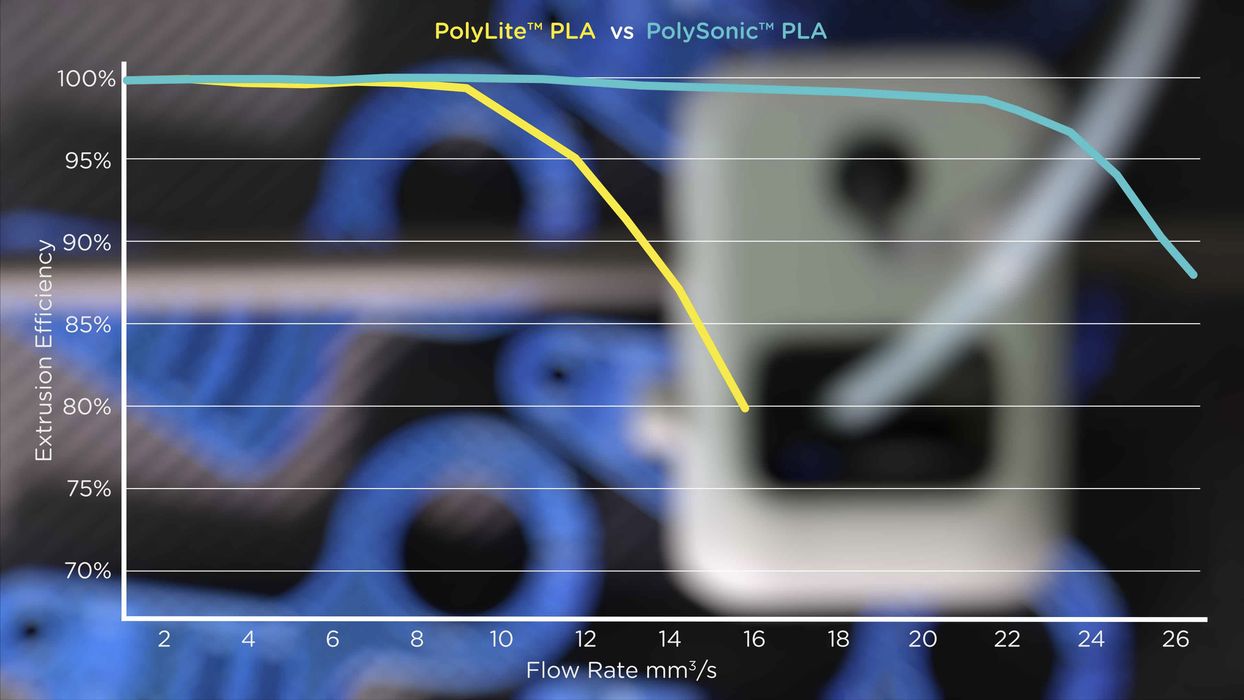

“Extrusion: It can extrude consistently at 24mm3/s on a popular extrusion system, in our case Hemera XS with Volcano hotend. Equivalent to 300mm/s at 0.2mm layer height with a 0.4mm nozzle. The Nozzle size and layer height are really important here, and an area where other brands make some outlandish claims based on printing speed.

This is why we standardised all our testing to a 0.4mm nozzle and a 0.2mm layer height, as this is what we believe to be the most common printing setup. With this set-up extruding at a volumetric flow rate of 29mm3/s, PolySonic can print at 363mm/s. However, if we use the same nozzle but change the layer height to 0.1mm, also a common setting for high detail, then the print speed can be 725mm/s. We believe this is how other manufacturers are defining ‘High Speed’ materials claiming 600 or 700mm/s print speeds.

Forming: The forming is inherently linked to the extrusion and is the most critical factor when fine-tuning the formula for PolySonic. By lowering the molecular weight of the polymer, we can get it to transfer heat quicker to the core and therefore melt faster. However, this comes with a lot of stringing and printing issues, such as drooping top surfaces over infill (Pillowing), poor overhangs, over-extruded bottom surfaces but under-extruded walls, rounded corners and loss of detail.

I think the most critical aspect is how well the material can cool down, as this was the bottleneck for a lot of high-speed printers and why we see static cross-bed auxiliary cooling fans on printers such as the Bambu X1C, and Creality K1. Having an extremely low coefficient of thermal expansion is very good for preserving detail in the final printed part. As all models and geometries behave differently, its generally a subjective measure rather than something we can scientifically quantify, so the definition stands as: At 24mm3/s, PolySonic maintains similar surface quality, overhang and bridging quality when compared to parts printed at classic speeds (6mm3/s)

Mechanical Properties: Mechanical properties will naturally decrease when printing faster as, there less time there is to thoroughly heat the filament which directly affects layer adhesion and extrusion efficiency. We define this as: At 24mm3/s, it maintains at least 80% of its overall mechanical properties when printing at a lower speed. (mainly: layer adhesion, tensile strength and impact strength).

This part is a little bit tricky, however, and in some of our marketing, we state that the tensile strength is only from 6% when printing at high speed, compared to classic speed. This is due to the testing sample and methodology which has become standard for all our materials and for many of our competitors. The problem here is that the 3D printed samples that are used in our testing ISO527 are not big enough to allow the printer to actually reach the full speed we want to achieve.

For the Charpy impact test machine and the bending strength machine, the dimensions of the printed specimen are critical to the set-up. This also allows us to easily compare results across materials and choose the correct properties for our application. The results of the test didn’t correlate with what we expected when comparing PolyLite to PolySonic and slow and high speed. However, The tensile strength testing machine is much larger and the printed dog bone sample can be scaled up to produce a larger specimen.

This is really where we saw the benefits of PolySonic and its these results that we used in our marketing content as it reflects a larger printed part where the printer has time to reach the requested 300mm/s print speed without decelerating for the next change of direction. In this case, the data on our TDS is the standardised data we use on all our materials and honestly doesn’t show the full potential of using PolySonic over PolyLite. We are planning a new set of mechanical tests for high-speed material to solve this issue in the future.”

Polymaker’s initial release of PolySonic will have two lines: PolySonic PLA and PolySonic PLA Pro. The Pro line has certain additives that provide better impact strength, making it similar to ABS in performance (aside from thermal resistance).

The basic PolySonic material now comes in five colors: white, black, red, blue and red at US$25 per kg, while PolySonic PLA Pro is available in black and white only at US$30 per kg spool.

That’s not a lot of color choice, but if I know Polymaker, they will soon solve that issue.

Via Polymaker

It is appreciable to see more peoples (such as Polymaker) using volumetric flow rate more commonly now !

(compared to ten years ago, we were a few, pestering at manufacturers talking only in linear speeds)