Charles R. Goulding and Preeti Sulibhavi look at the possibiliites of 3D printing for the bicycle industry.

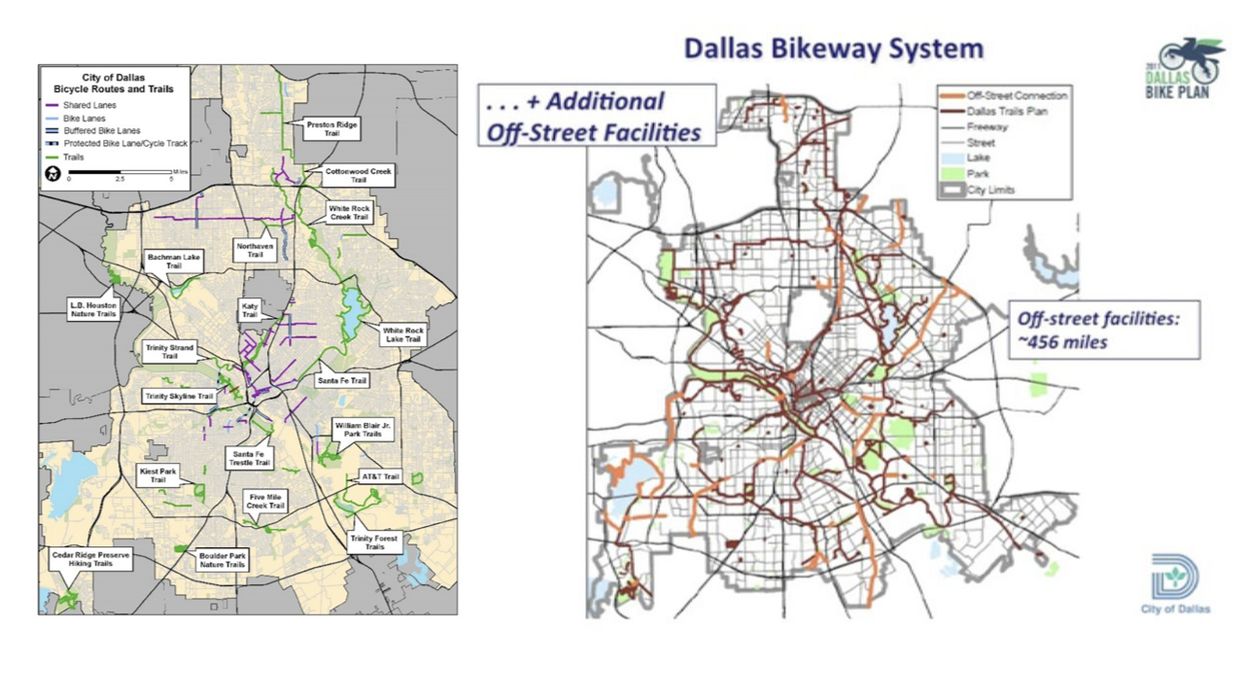

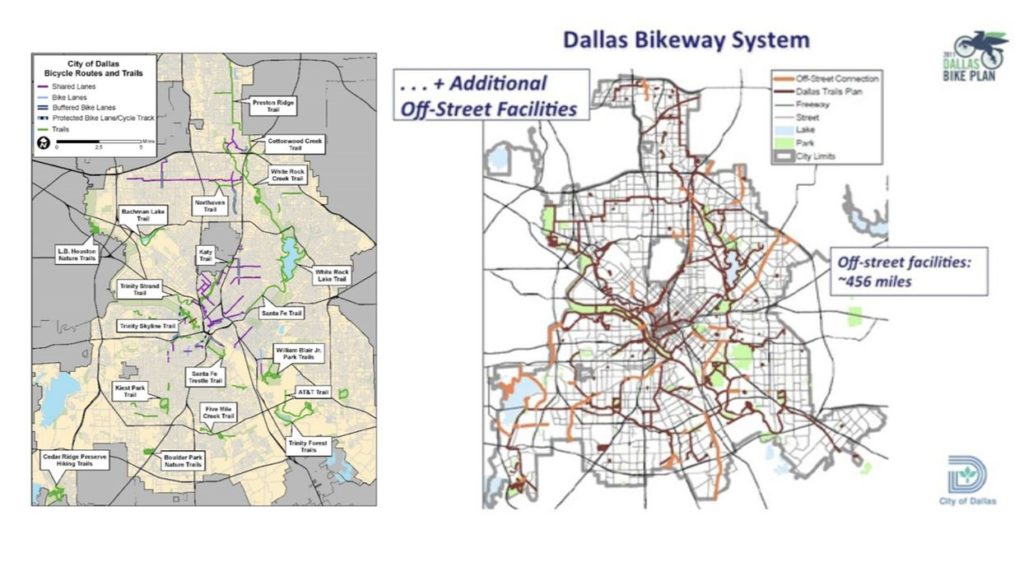

In the quest for weight reduction and high-performance bike components and accessories, bicycles have become one of the major 3D printing categories. Between the health, environmental and business benefits, the 3D printing industry should be one of the major supporters of bike infrastructure. Recently, the fast-growing city of Dallas, Texas has come under criticism for failing to create adequate bike infrastructure.

The Dallas inadequacies are accentuated by comparing it to fellow Texas city, Austin, which has supported bike trails. Houston, Texas has 4 times the miles of protected bike trails. We have written previous Fabbaloo articles regarding improved bike infrastructure in “The Empire State Trail: Opportunity for Recreational Activities and 3D Printing”.

Other cities that have had great success with bike trails include Portland, Oregon and Boulder, Colorado. One criterion that bike riders use when migrating to other locations is “bike friendliness” and the number of protected bike trails. The bike and 3D printing enthusiasts in other locations with inadequate protected bike infrastructure should marshal the data from the cities that are progressing and use the benefits to champion their cause.

As previously detailed in our other articles, there are many applications for 3D printing in creating bicycle components, parts and accessories.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Re-cycling the Point

Cycling has become a very popular pastime for many people. The 3D printing industry has already been partaking in many aspects of biking, whether it be accessories or components and parts, there is a great benefit here.