Cybe announced a new construction 3D printing material that is nearly carbon neutral, and this changes the game completely.

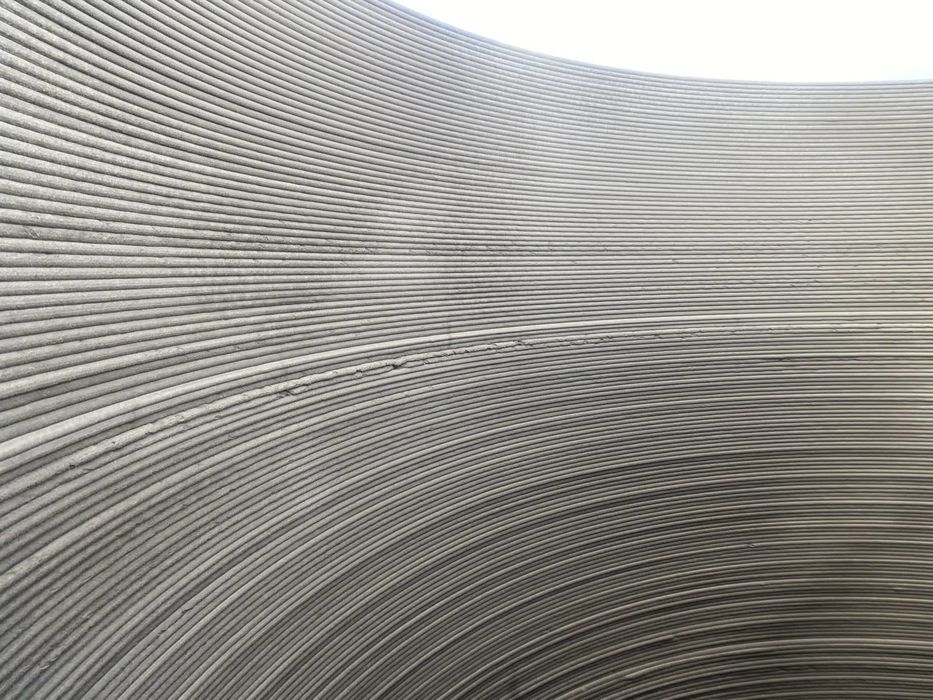

Netherlands-based Cyber is one of several companies exploring the construction 3D printing space. These operations typically use concrete extrusion to produce huge structures, typically buildings. They can quickly print the concrete portions of buildings, which are then completed using traditional trades for HVAC, plumbing, electrical, etc.

While construction 3D printing can be quick, it isn’t inexpensive even though somewhat less concrete is typically used. The problem is that in order to print structures layer by layer, the concrete must set very quickly. Normal concrete can take days to properly set, and that’s unacceptable if you are printing a new layer on top only minutes later.

Because of this most construction 3D printers have to use relatively expensive concrete mixes that are designed to cure rapidly. This increases the cost of 3D printed construction projects and thus deters some from participating.

The use of concrete is important because its production is one of the major sources of CO2 emissions on this planet. Apparently some eight percent of annual CO2 emissions are caused by concrete production. This factor will dramatically increase in importance in coming years as the climate emergency worsens.

Cybe had been using a special concrete mortar mix of their own that offered a 32% reduction in CO2 generation, but now they’re on to something even better.

They’ve teamed up with Hive3D Builders, whose partners have created a new specialized concrete mix that decreases CO2 emissions by a staggering 93%. This geopolymer cement material is nearly carbon neutral.

According to Cybe, this material is not only stronger than traditional cement, but is also priced at about one-third of typical 3D print cements.

This is a very significant development for construction 3D printing: a new material is stronger, eliminates emissions and also costs less. That will carry through to project proposals that will have lower prices and therefore attract more buyers to the technology.

Construction 3D printing is still quite new, and it’s always challenging to attract new customers. That’s particularly so if the costs are high. With this development the costs are lowered and more projects could make use of the tech.

Further, there will be an increasing number of projects that require specific CO2 reduction goals be met, and it’s quite possible that the new material from Cybe could greatly assist in achieving those goals, regardless of the cost.

There is no doubt that this material development will generate significantly greater use of construction 3D printing in the long term.

Via Cybe