Creality announced the K1C desktop 3D printer, and we have the details.

Creality’s K1 system has been extraordinarily successful, providing high speed operations and a generous enclosed build volume. Now they’re introducing the K1C, which includes quite a number of enhancements.

The key feature of the K1C is that it can, out of the box, handle carbon fiber-reinforced filaments, such as PLA-CF or PETG-CF. These are increasingly used materials as they are easy to print and produce very strong parts — if the printer is able to handle the materials. If you haven’t guessed, that’s what the “C” in the name is all about.

Here are the basic specifications:

- Build volume: 220 x 220 x 250 mm

- Filament: 1.75mm

- Maximum print speed: 600mm/s

- Acceleration: 20,000mm/s/s

- Minimum layer height: 0.1mm

- Standard nozzle diameter: 0.4mm

- Maximum nozzle temperature: 300C

- Maximum build plate temperature: 100C

- Build plate: standard “mag flex” plate with PEI coating

- Calibration: automated

- Touchscreen: 4.3″ color

- Vibration compensation and input shaping

- Power loss recovery

- Filament runout sensor

While the K1C shares many specifications with the previous K1 model, including the very fast 600mm/s print speed, there are a ton of interesting improvements.

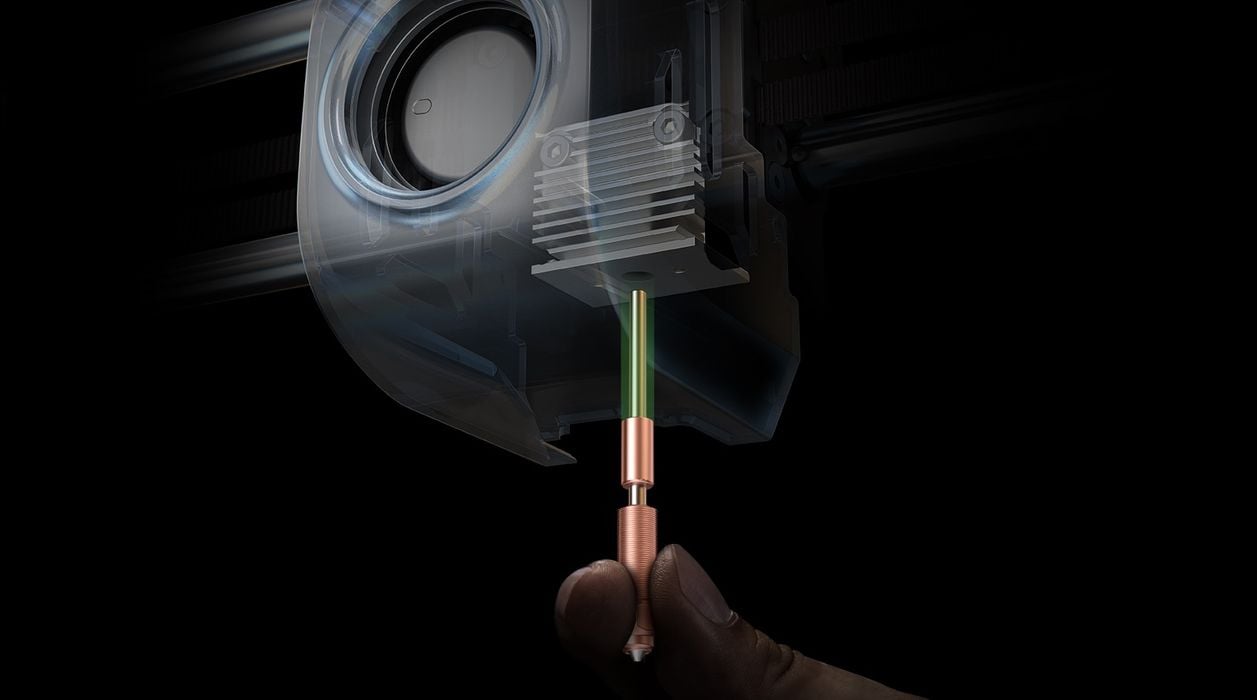

First up is the extrusion system.

The K1C’s extruder is all-metal, and includes new features that ensure a very strong grip on the filament. Creality states that it will have “1000hr clog-free extrusion”. I’m not exactly sure what that means, but it appears they are quite confident that the reliability of this extrusion system is vastly improved.

The nozzle on the K1C is designed for easy replacement. They say it can be replaced with “one hand”, and that’s much easier that most other desktop 3D printers. I presume they will also announce different nozzle diameters that fit into the K1C. The nozzles are made from hardened steel, and that’s what enables the carbon fiber material usage — standard brass nozzles would quickly wear out with these abrasive materials.

Creality has redesigned the fan systems on the toolhead, which includes a fan for cooling above the heatbreak and cooling the printed part. They explain:

“The hotend and part cooling fans on the printhead are now dynamically balanced so they are less likely to wobble, minimizing ringing or ghosting.”

This is quite interesting because I don’t know of other printer manufacturers taking this step. I didn’t even realize that the fans could generate much effects from wobbling.

Another interesting feature is a chamber fan. This would redistribute heat more equally inside the chamber, and be quite a differentiator. Normally heat inside an enclosed 3D printer is generated from the print surface, and then randomly captured in the chamber. The result is uneven heat, where it tends to collect at the top of the chamber.

With the chamber fan the thermal profile should be mostly equal throughout the chamber. This should increase print quality because extrusion conditions will be near identical throughout all layers.

The K1C now includes an onboard webcam that observes print operations. It uses an AI system behind the scenes to automatically detect print failures, and consequently notify operators to take action. It can also capture timelapse videos for future use.

Another very interesting feature is something Creality calls “quiet mode”. By my measure, all of today’s 3D printers are pretty quiet compared to the original devices of ten years ago. The use of advanced stepper motor systems dropped noise levels considerably.

However, here it seems that Creality wants to drop the noise levels even further. They say that when activated, the K1C produces only 45dB of noise, which is basically silent. They say it’s “as loud as turning pages in a book”, and that’s pretty quiet.

How do they do this? From the image shown above, it appears they are slowing down the machine’s print speed. It’s not clear at this point, but perhaps quiet mode implies slower prints? We will have to see how this turns out.

There is a new filtration system that uses activated carbon. This should capture VOCs before they are emitted to the work area, making the device quite a bit safer, particularly if it’s in continuous use.

Creality also describes a method of batch printing in which you can continue printing subsequent jobs even though one in the batch had failed. This sounds like a very useful feature, and will be welcomed by anyone who’s had that particular issue.

Finally, the K1C has increased levels of automation. The K1C is fully assembled from the factory and includes a boot up procedure that performs the necessary calibrations. That should greatly help those new to 3D printing that would otherwise be deterred by a need for technical calibrations done manually.

The K1C carries a pretty good price for the combination of features and capabilities: only US$559. That’s quite a bit lower than most of their competitors and among the lowest options for printing good quality carbon fiber parts reliably.

Looking at all these features as a whole, it seems that Creality has actually produced a professional-level 3D printer that is masquerading as a desktop device.

Via Creality