Bondtech and Slice Engineering announced the immediate availability of a series of upgrades designed for most of the Creality line of 3D printers.

Popular Creality 3D Printers

Creality is one of the popular low-cost 3D printer manufacturers, and there are no doubt tens of thousands of their units placed worldwide. We have one in the lab here somewhere, a CR-10S that we reviewed some time ago.

One of the reasons the Creality equipment is so popular is that they offer good functionality with a reasonable expectation of reliability and quality at a very low cost as compared to many other options. The company has carefully balanced these factors to come up with an attractive option, and the process of achieving that balance can be challenging.

While the price point of Creality equipment attracts many to the devices, there are those who wish to make the machine even better. In other words, they have a slightly different opinion on the balance of cost vs features. One way they can resolve those gaps is to modify the machine after purchase with third party upgrades.

This is commonly done on low-cost 3D printers by those who are technically capable of doing so. They’re a subset of the Creality user base to be sure, but usually are talented individuals wishing to make things better.

Now their upgrade options just got better with a joint announcement from Bondtech and Slice Engineering to provide a set of extruder and hot end upgrade paths for most Creality equipment.

Bondtech DDX For Creality 3D printers

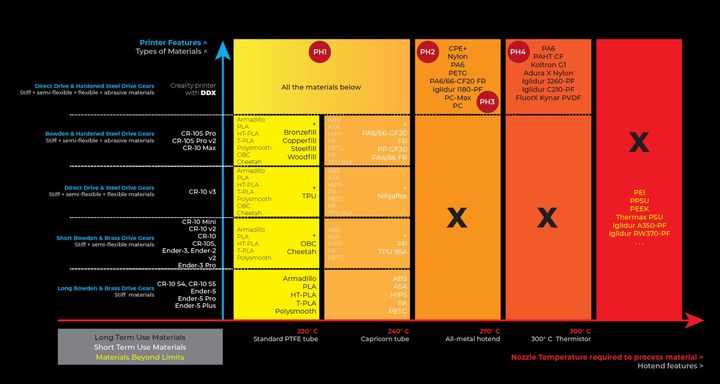

The companies announced the “Bondtech DDX Direct Drive eXtruder for Creality”, which is targeting the Ender-3 family; Ender-5 family; CR-10 and CR-10 Max; CR-10S family; CR-10S Pro; and Pro v2, which happen to be the most popular devices in Creality’s product catalog.

The upgrades enable the use of Bondtech’s powerful extrusion technology and Slice Engineering’s hot ends. These high-end components are often used on name-brand 3D printers but are not present on Creality gear because of the design choices Creality made during product development. Remember, Creality has to ensure the final product has the right price for the market, which they have done. Part of that development involves choosing extruder and hot end components.

But now these two essential 3D printer components can be swapped out for better options from Bondtech and Slice Engineering. The results should provide for higher-quality 3D prints and increased reliability.

Creality Direct Drive

Many of Creality’s systems use Bowden extruder systems, which, while inexpensive to produce and generally effective, are typically unable to 3D print flexible materials properly and reliably. However, with these DDX upgrades for Creality equipment, a direct drive is installed and thus the Creality equipment can then far more easily 3D print flexible filaments.

Creality High-Temperature 3D Printing

Bondtech’s Product Manager, Nuno Santiago, said:

“With Bondtech DDX for Creality, we empower users to start with a solid and reliable direct drive base setup – using many stock parts like both fans, heater, thermistor and hotend – and deliver a clear upgrade path with Copperhead or Mosquito hotends and Slice Engineering thermistors and heaters.”

One upgrade option allows the use of temperatures up to 450C, enabling the operator to 3D print higher-temperature materials. This alone could be of significant interest to some Creality users.

This is enabled with a four-phase approach to the upgrade, from which users can select how far along they wish to proceed. The phases start with a simple extruder upgrade, then move on to heartbreaks, hot ends and ultimately the entire extrusion system.

They explain:

“The news on Phase 4 are the introduction of a new Slice Engineering Thermistor, rated up to 300°C, that will pair with the existing High Temperature Thermistor, rated up to 450°C, to extend the range of materials available to Creality users, usually limited to materials processed under the 260°C limit.”

However:

“Phase 4 is compatible with a narrow variety of models, focusing only on the prosumer models from Creality, and will require updating the firmware with a fork of Marlin 2.0.6 made by Bondtech.”

Nevertheless, this set of upgrades should be of considerable interest to the large portion of the 3D print community that makes use of Creality equipment.

Via Bondtech and Slice Engineering