An announcement from Stratasys hints at where the future of 3D printing might be heading.

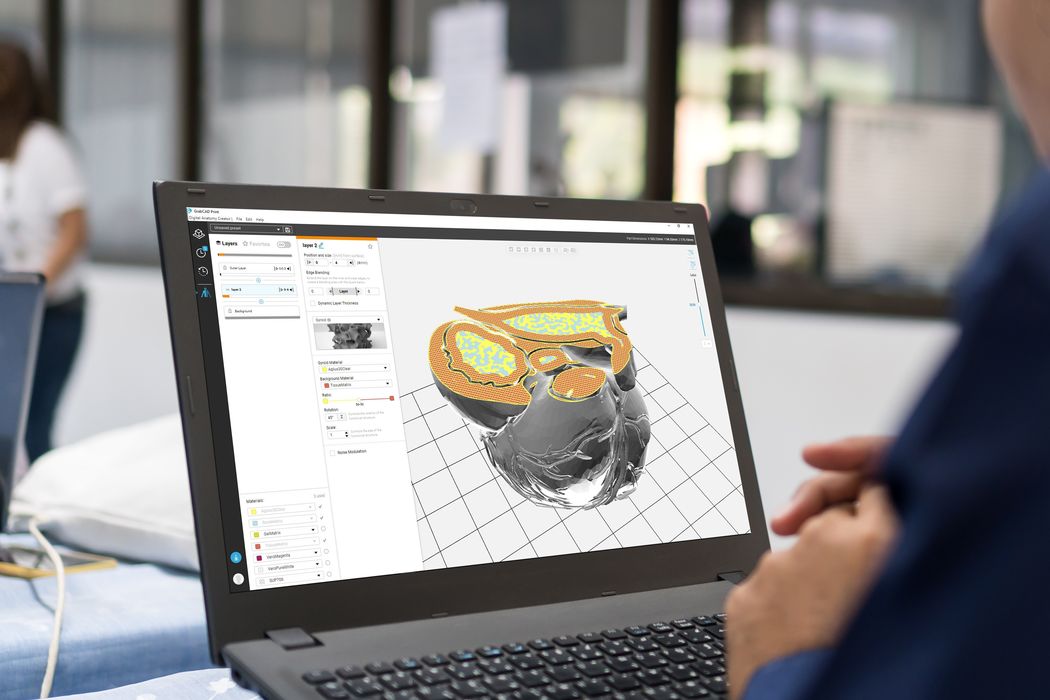

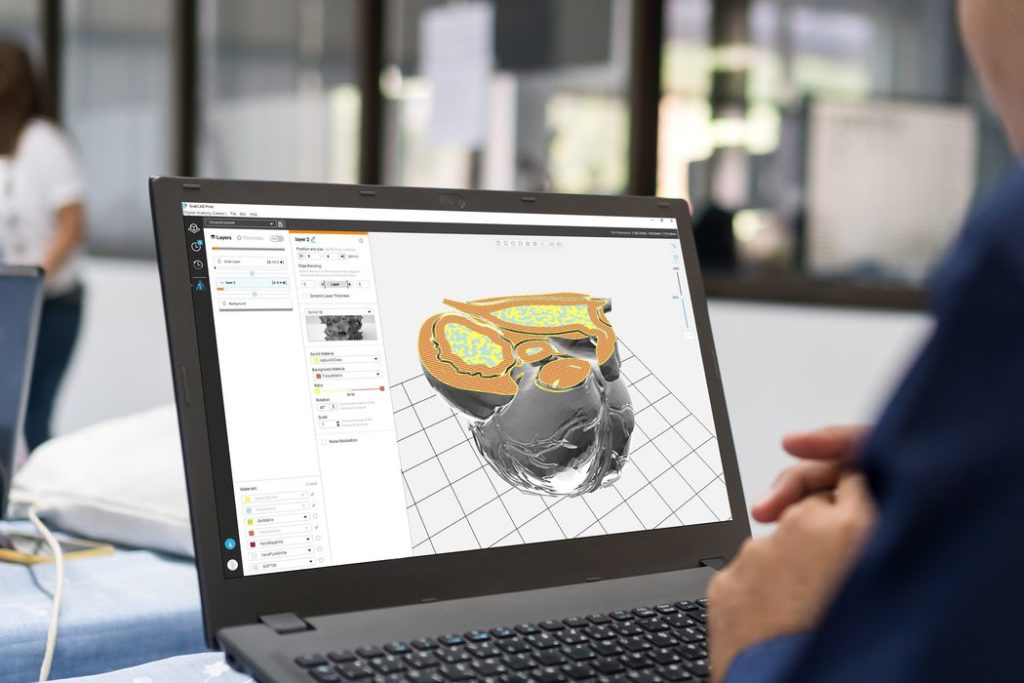

The announcement was regarding a new software system, the “Digital Anatomy Creator”. This is a specialized 3D CAD tool that allows users to develop 3D anatomical models with unprecedented ease and accuracy. Stratasys explains:

“Stratasys Digital Anatomy printers can produce medical models across a spectrum of applications, from diagnosis to patient education. With the Digital Anatomy Creator users have access to additional options and controls to calibrate their printers’ materials to meet their specific anatomic model needs, allowing them to explore, customize and create ultra-realistic models that behave and respond like the real thing. Further, Digital Anatomy Creator allows users to create, replicate and share designs across a community for patient-specific anatomies.”

Manager of Innovation, Imaging and Simulation Modeling for Seattle Children’s Hospital, Seth Friedman, PhD, said:

“The Digital Anatomy Creator is the missing link between the patient, the printer and the final printed 3D anatomic model. This new software has allowed us to personalize our anatomic models to a mind-blowing level – we can now provide a level of care that is truly personalized to each of our patients, which is really important when working with children and their caregivers.”

Tbe Digital Anatomy Creator is used to develop complex 3D anatomical models for production on Stratasys’ full color line of 3D printers, headed by the J750. These devices are able to print objects with photorealistic colors and textures, making it quite appropriate for producing medical models. These can be used for educational purposes, training or surgical rehearsals and planning.

That’s all good news for the healthcare sector, but I had a thought about what this might mean for the 3D print industry as a whole.

Here we have a company developing software that enables a group of users in a particular domain to easily create 3D models of the type required.

Points to note:

- The hardware (printers) were not changed to make this system work, only the software situation was changed (created, in this case)

- The users were unable to use existing 3D software to accomplish easy creation of the desired 3D models

This tells me we have a software problem. When you have to create new software to enable people to use existing hardware, this means the existing software is not appropriate.

I’ve seen this before in other industries.

Consider the current breadth of 3D CAD tools on the market. There are dozens, with many specializing in particular domains. By “specializing”, I mean these 3D tools offer features that make it far easier to perform actions relevant to a particular domain. For example, a mechanical design tool might include a way to automatically generate a threaded cylinder, whereas an artistic 3D tool might have no need for such a feature.

There are currently many 3D software tools dedicated to mechanical parts, architecture, artistic sculpture, dental models and a few more. Some, like Carbon’s Design Engine, could be applied to several industries with it’s advanced lattice generation capabilities.

In this case, Stratasys has created a new one dedicated to anatomical design.

Their new product literally opens up a new world for a specific group of professionals to explore and make use of advanced 3D hardware and materials.

Now the important question: what other domains deserve specialized 3D software? What other groups could be enabled to use 3D printing that presently have no effective means of entry?

If such software were developed, it could lead to additional sales of existing equipment and grow the 3D print ecosystem overall.

Via Stratasys and BusinessWire