Could the Bedslinger 3D printer design disappear?

There are hundreds, perhaps thousands of different designs for desktop FFF 3D printers. While each extrudes softened filament layer by layer, the motion systems of the systems fall into only a few categories.

The five main categories of 3D printer motion systems are Cartesian, Delta, CoreXY, Robotic, and what’s known as a Bedslinger.

Cartesian 3D Printers

A “Cartesian” system simply involves three axes of motion that are independent. Typically a separata motor will drive each of the X, Y and Z axes to affect motion. The X and Y axes will move the toolhead around the plane of printing, while the Z axes could either move the build plate or the an X/Y mechanism.

Cartesian systems were the original approach for 3D printing, and are still very popular today, although many manufacturers are opting for other approaches for a variety of reasons. However, it is still used for very large volume 3D printers as the other approaches have issues when scaled up.

Delta 3D Printers

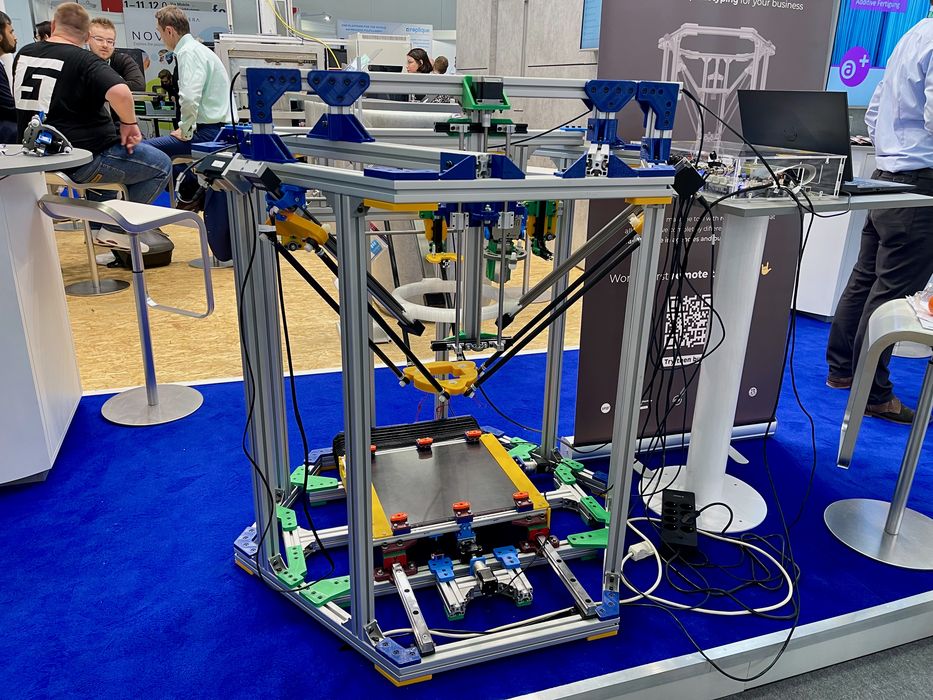

In a Delta motion system, the toolhead is held by a tripod-like mechanism that maintains level. A Delta system prints within a cylindrical build volume, and is very lightweight. The lightness theoretically allows the system to print faster because there is less mass to deal with when the direction of motion changes.

However, Delta systems by definition must be somewhat tall to accommodate the motion system. Often you’ll see Delta 3D printers designed for tall build volumes.

CoreXY 3D Printers

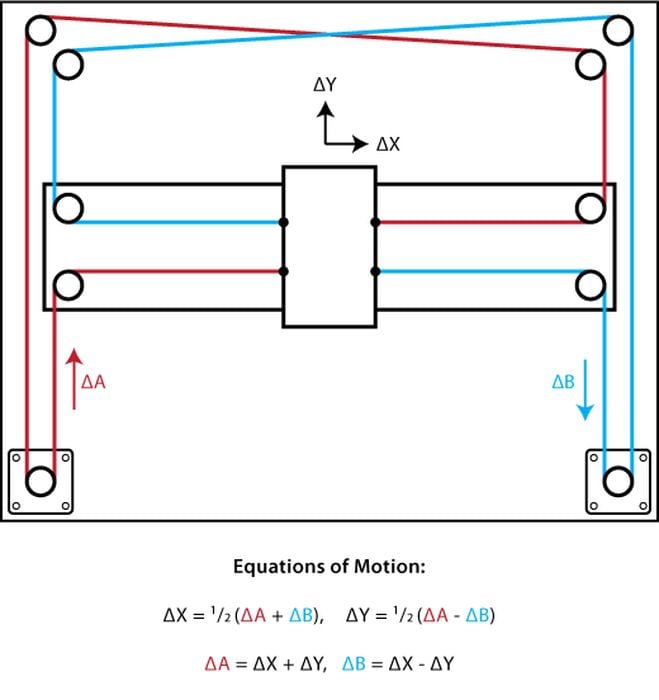

Another popular approach is known as “CoreXY”. This is somewhat similar to Cartesian, except that the X and Y motions are integrated, usually with a belt drive arrangement as shown here. Movement is accomplished by coordinating motor activity.

The key advantage of the CoreXY system is that there is less mass to move about because the motors are in fixed positions, as they are in a Cartesian system. However, CoreXY systems are somewhat complex as you can see in the above diagram. They also cannot be easily scaled to large volumes because of belt issues.

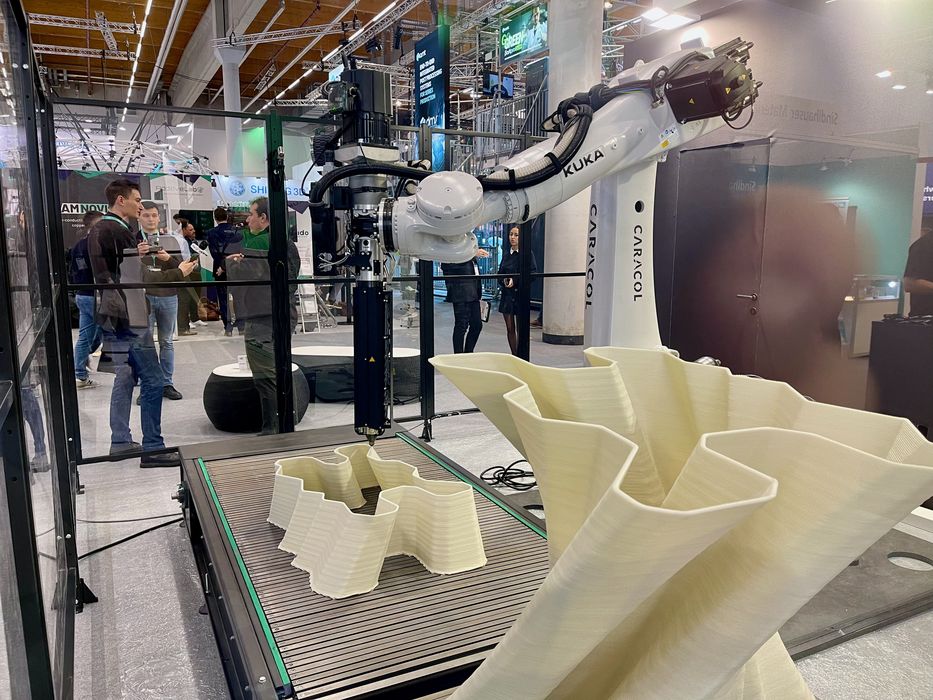

Robotic 3D Printers

There are some robotic 3D printers, which are typically a commercial robotic arm with a 3D print toolhead on the end effector. These robotic systems provide considerable freedom of movement and thus allow non-planar 3D print movements, which is sometimes advantageous. However, the cost of the robot arms is quite significant, meaning this approach is used only in larger scale expensive designs.

Bedslinger 3D Printers

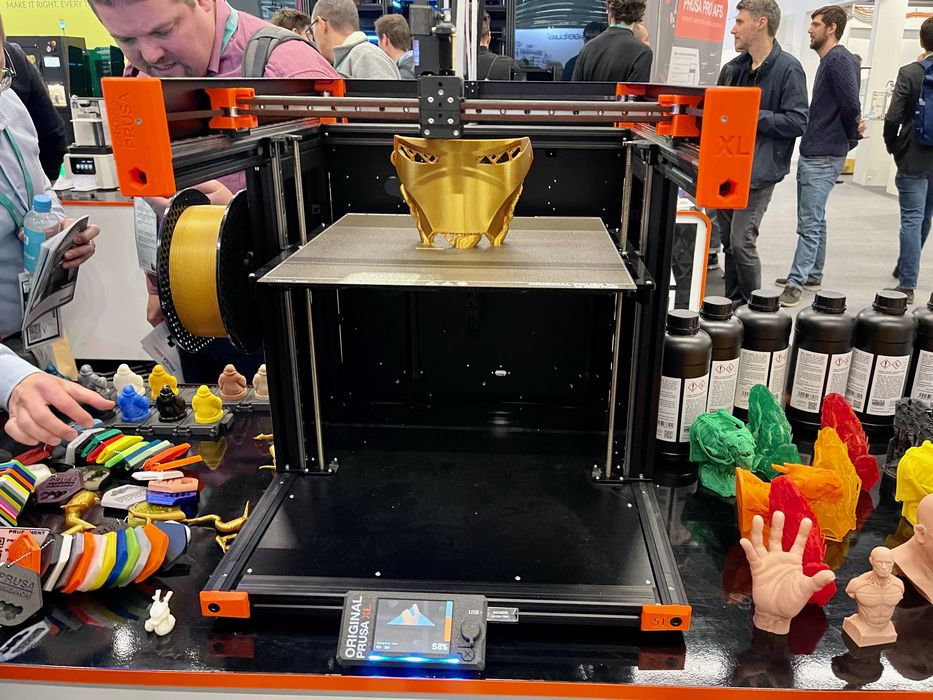

Finally, there’s what’s known as the “Bedslinger”, or “i3”. The Bedslinger joins the X and Z axes together, with a separate Y axis to operate the print surface. The X axis moves across a rail and can be raised or lowered, but the print surface moves forward or backward.

The advantage to the Bedslinger approach is that the machine design can be quite inexpensive. Only a single hoop is required for the frame to hold the X and Z axes, whereas in a Cartesian system you really need a full cube frame.

The problem with the Bedslinger approach is that the print surface moves. At slow speeds, this isn’t that much of a problem, but as print speeds increase there can be considerable vibration. The vibration results from the growing print wobbling back and forth as the moving print surface tosses it around. This issue is particularly evident with tall, thin prints. Imagine holding a rod at the bottom and moving it back and forth quickly — watch the top of the rod to see what happens; it’s much like a skyscraper in an earthquake.

The Bedslinger concept allowed for the development of very inexpensive desktop 3D printers, some of which are now US$200 or less. However, with that price print speed is forever compromised.

In recent years there has been a dramatic increase of interest in print speeds. Much investigation has taken place by corporations and open source projects to identify ways to speed up prints that can otherwise take days to complete.

As these solutions enter the commercial market, they will be significantly faster printers than the typical Bedslinger of today. As their prices fall over time, I wonder whether Bedslingers have much of a future in the long term?

It may be that we could see this now-popular style of 3D printer begin to fade away, as far faster equipment could emerge with pricing that’s not much more expensive. Bedslinger prices have mostly bottomed out, meaning they don’t have much, if any financial room to compete with faster designs that are being developed.

What do you mean coreXY cannot be easily scaled larger because of the belt? You just get a bigger belt. My coreXY is as big as the biggest mainstream consumer printers out there. It’s not complicated, expand the frame, change to bigger belt and bigger plate.