New chemical recycling process preserves material performance without downgrading.

Sustainability is becoming more important to consumers. As a result, manufacturers and engineers are beginning to look for more ways to build sustainability into the life cycle of products. One concept gaining traction is the circular economy. According to the Ellen MacArthur Foundation, an organization dedicated to promoting a circular economy is one that focuses on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

For products made from commodity plastics, a transition toward a more circular economy could mean less packaging, a transition from nonrecyclable materials such as composites or multi-materials to more recyclable alternatives, and an increased use of recycled materials.

Recycling is not a perfect process. Each time many plastics are recycled, they degrade in quality. However, according to a February 2021 report published in the journal Nature, researchers used polyethylene-like polymers derived from plant oils to demonstrate a chemical recycling process that offers a closed-loop recycling alternative that retains the materials’ high-performance properties.

According to the report, this process requires less energy to recycle polyethylene compared with existing methods, which involve heating the material to 800°C in order to break carbon bonds. The report noted that “of central importance are low densities of break points in the polyethylene chain such that the crystalline structure is not affected, and consequently properties like mechanical strength are not compromised … the alcoholysis reactions used here are essentially thermoneutral equilibrium reactions shifted to depolymerization by an excess of solvent.”

Closed-Loop Recycling

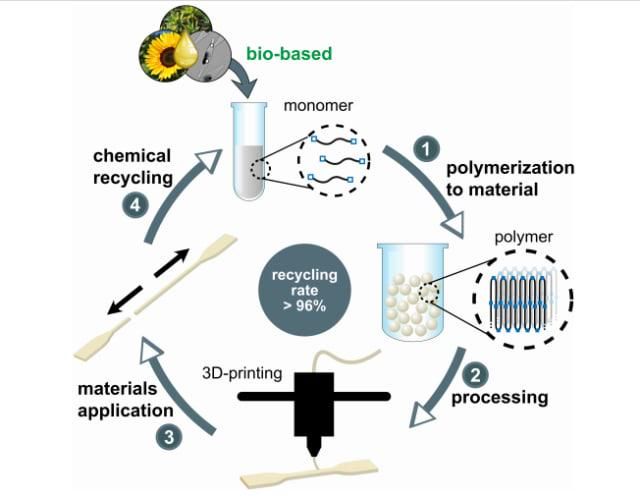

Referring to the chart above, here’s how the closed-loop system works.

- Monomers obtained from the biorefining of plant or microalgae oils (“bio-based,” top inset) are polymerized to give polycarbonates and polyesters polyethylene-like properties.

- These materials are then used in manufacturing (such as 3D printing).

- After the useful service life of the polyethylene-like polymers (the diagram shows a test part used for tensile testing), they are recycled.

- Chemical recycling via a solvolysis process to the underlying monomers is enabled by the functional groups present in the polymer backbone. The recovered monomers can be repolymerized to materials with properties on a par with the initial polymers for an overall recycling rate that is greater than 96 percent.

The researchers used polyester-18 and polycarbonate-18 in their testing. Commercially available, renewable 1,18-octadecanedioic acid, produced from large-scale biorefining of plant oils by olefin metathesis technology, was employed as a starting material.

In addition to the tensile testing bars, the researchers manufactured several more functional and varied items from the plastic materials, such as the smartphone case shown above. A smartphone case is an excellent example of a product for which this recycling process could be desirable, due to the life cycle of the average smartphone.

Read more at ENGINEERING.com