Thanks to intelligent 3D nesting, textured surface design, a sophisticated SLS build manager, and more.

CoreTechnologie is a leading software provider for 3D CAD data conversion, founded in 1998, with the mission of helping organizations optimize interoperability. The company’s yearly growth rate of 20% is a result of the team’s commitment to innovation – which sees 35% of its revenues reinvested into the development of new products and technologies.

Innovative AM software

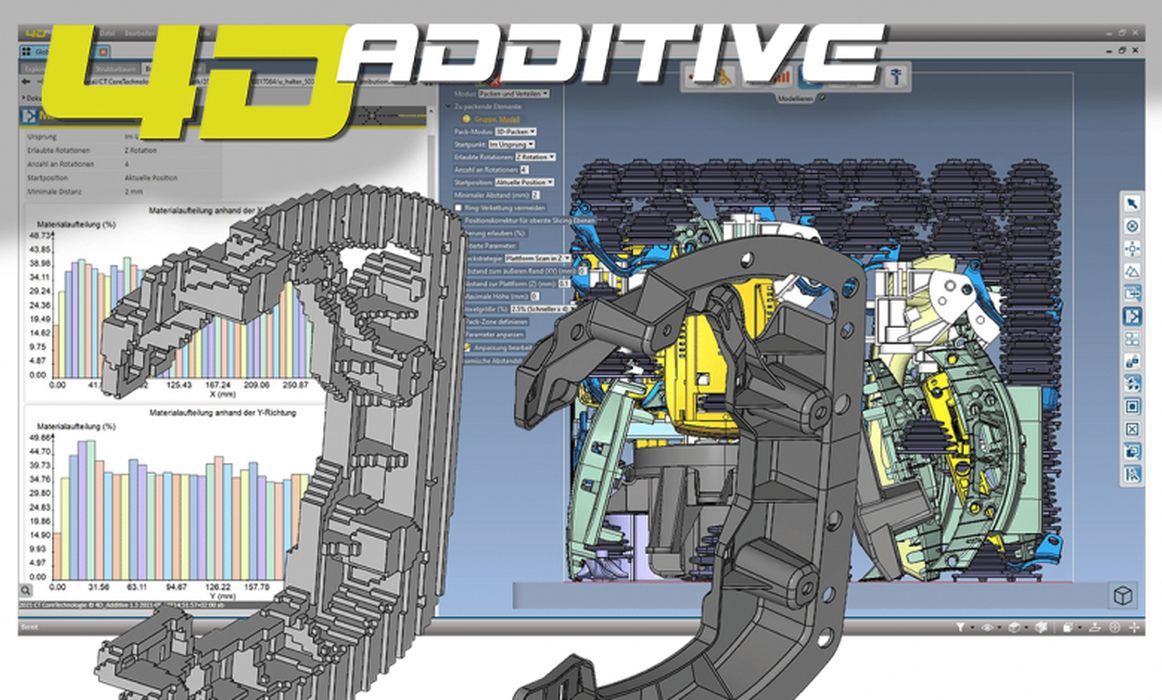

CoreTechnologie’s 4D_Additive software is one of the most powerful technological bridges between CAD and 3D printing to date, and refines the seamless data management for additive manufacturing. 4D_Additive enables the fast and precise preparation of CAD data for 3D printing, and offers powerful tools for repairing CAD and STL models, performing 3D nesting, part analysis, modeling, texturing, and creating advanced lattice structures – all within single software – complemented by an easy-to-use, app-style graphic interface.

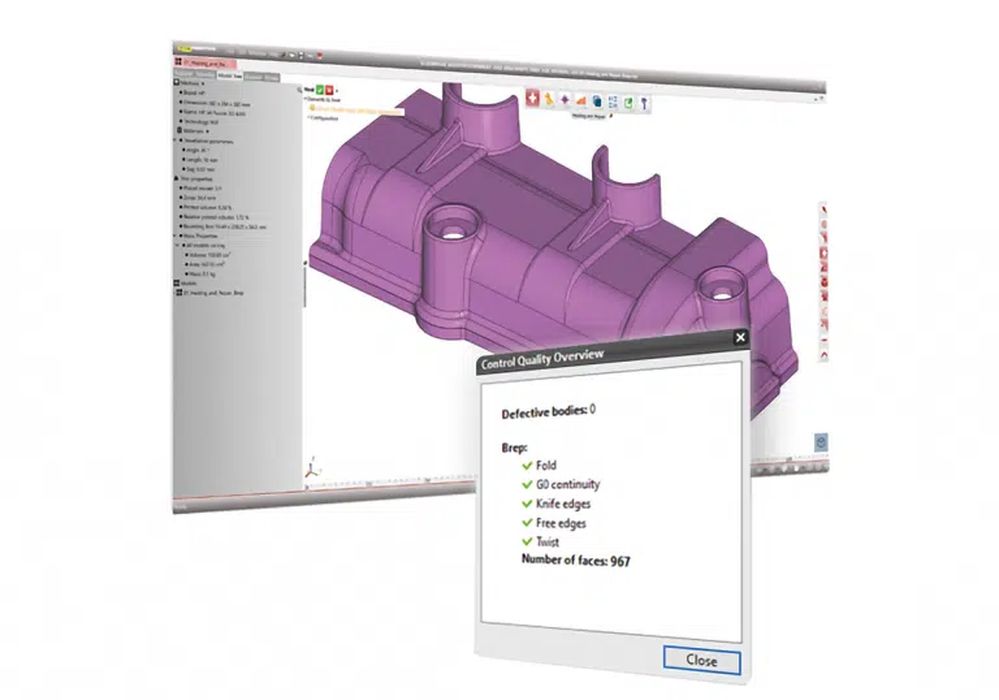

Quality and precision

The hybrid geometry kernel that handles exact CAD geometry, in accordance with established engineering standards, guarantees superior printing quality, while the Healing function automatically removes free edges, closes gaps, and corrects overlapping elements and twisted faces. The Filter function locates the remaining problems, while the Repair function fixes them – all within a matter of seconds.

STL, and even Scan data, can be automatically repaired, to perfect volumes and within seconds – thanks to the new Marching Cube repair technology – while the number of triangles, as well as the file size, can be efficiently reduced with thanks to the Mesh Simplification function.

The software offers interfaces for 24 major formats, some of which include Catia, Nx, Solidworks, Creo, Step, and Jt.

3D nesting with intelligence

4D_Additive’s Intelligent 3D nesting provides superfast automatic packing, whilst ensuring high build density and optimal quality. The nesting function uses multi-processing and offers maximized packing speed, accuracy, and density, as well as a uniform distribution of the parts in the build space – to avoid heat concentration. For mass production, the new Powercopy strategy packs identical parts, with the same impressive speed and packing density. The workshop is completed by functions such as collision detection and distance analysis.

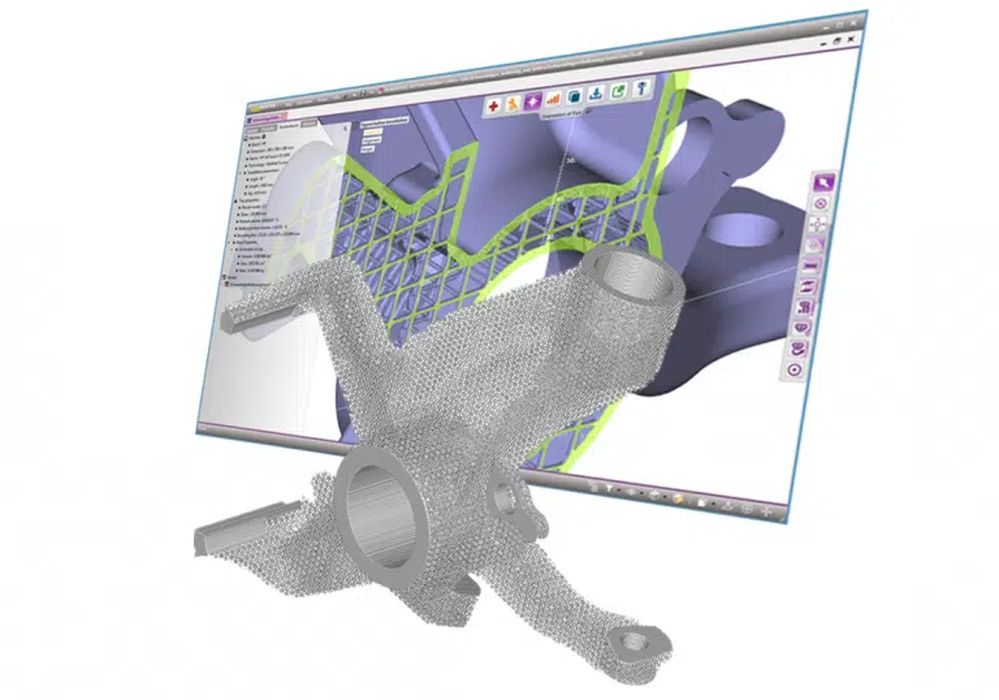

Gyroid lattice structures

Within a matter of seconds, the software’s Advanced Lattice module creates 21 different types of internal, external, and skin structures for the design of lightweight components, or medical applications. Structures that emulate natural grids, such as gyroid, trabecular, or stochastic, are automatically generated to optimize stability, stress distribution, and shock absorption. The variation of the functional zones and their density, as well as the use of different grid types, allows for the exact adaptation of the geometry to the required properties. In addition to this, complex 3D lattice geometries can be sent directly to finite element analysis tools with the new Nastran interface.

Read the rest of this story at 3DPMN