Do you have complementary 3D printers? Don’t know what that is? Read on!

There are countless 3D printers now on the market, made by hundreds of manufacturers. Many are available worldwide, while others are sold only within certain regions.

These machines use several different 3D printing processes and variations thereof. They’re priced at different levels and offer different material capabilities.

With such a wide choice these days it should be relatively easy to choose the one, true machine that fits your needs.

Right?

Wrong. That’s almost never possible.

Every single 3D printer on the market has something that will affect choice: constraints.

There are functions a machine can do, and those it cannot. A small-volume 3D printer cannot 3D print larger parts. A FFF device cannot produce smooth print surfaces. A metal 3D printer cannot produce polymer objects. And so on, down deep into the machine specifications.

While you might be able to identify a 3D printer that meets the needs of a specific project in terms of material availability, price, speed, and print quality, things may change on the next project.

Those project changes could be quite subtle, yet suddenly reveal your “ideal” machine choice to be inadequate. By using a non-optimal machine choice on a project, you may end up with non-optimal results.

What’s the answer here?

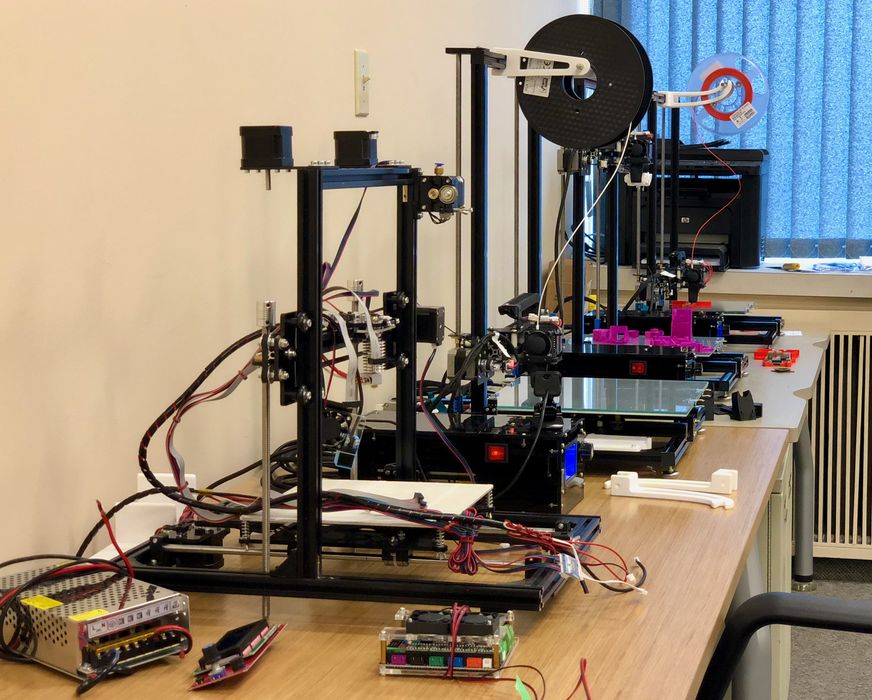

I believe the answer is complementary machines. This is a concept where instead of having a single choice of 3D printer, you have two or more on hand. The idea is to have each machine type cover off a certain envelope of requirements, in hope of providing a wide variety of functionality.

If configured with complementary 3D printers, then each projects simply needs to select the right machine for the job — or part of the job.

Too often companies and individuals persist in using the “wrong” machine for the job because there’s an assumption that the machine you have is the one you must use. Sure, investigate the possibility of doing so, but if it isn’t the best option, why don’t you have an alternative handy?

3D printers are just tools like any other. A good workshop doesn’t have just one tool, it has many different tools for different purpose. You may have different types of hammers or screwdrivers, so why not 3D printers?

Today’s price-performance ratio for 3D printers is at its highest level ever, and this lessens the financial barrier for those considering a complementary 3D printer strategy. That is true not only for companies, but also for individuals. For only a few hundred dollars, quite competent desktop 3D printing equipment can be obtained. Similar price decreases and performance increases have occurred on industrial equipment as well.

How do you determine what makes up a complementary 3D printer configuration? The key is that it is for your work, and thus will vary from place to place. If I were determining a configuration, I’d first consider the type of work taking place, and do a bit of extrapolation regarding material choice, part size and quality.

One approach is to buy first the machine that best matches current activity, and then add more equipment as needs vary. As the machines accumulate in the workshop, you have increased tool choice and can make better selections.

These different machine styles are not often found within the product line of a specific vendor, although there are some that offer equipment with different 3D printing processes. Where possible, stick with the same vendor, but at the same time be open to other alternatives to expand the envelope of making possibilities.