COBOD announced their partner is using the BOD2 construction 3D printer to build a three-story apartment building in Germany.

COBOD is one of the leading producers of construction 3D printers, which are essentially massively-scaled up RepRap-style 3D printers that use concrete extrusion instead of thermoplastic.

While that sounds straightforward, it is by no means easy. The sheer scale of the BOD2 implies all kinds of challenges that have been overcome during the development of the machine.

3D Printed Apartment

The latest project takes place in Wallenhausen, Germany, and is being undertaken by PERI Group, COBOD’s German partner. They are “one of the world’s leading suppliers of formwork and scaffolding systems as well as civil engineering solutions,” and have been working with Denmark-based COBOD for some time. They’ve undertaken previous construction projects with the BOD2, but the latest project is certainly the biggest yet.

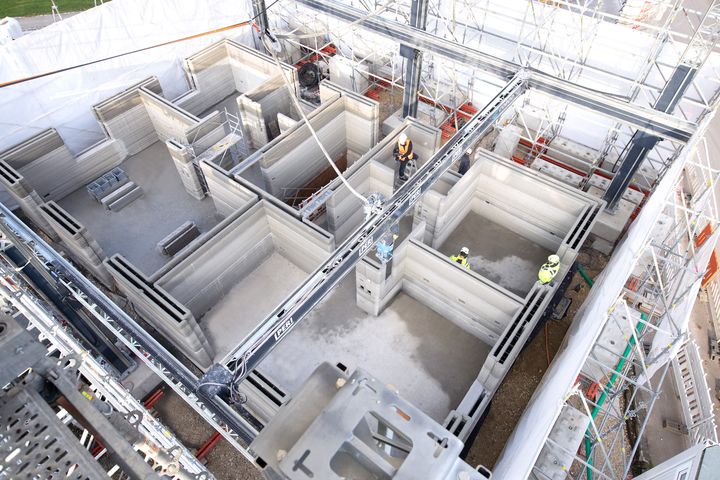

The apartment block will feature five apartments and will total a huge 380sm (4000+sf) of area. To build this, the BOD2 has been configured as 20m long, 12.5m wide and 7.5m tall. COBOD says the device will be able to extrude concrete precisely at up to 100cm/sec, or 10 tonnes of material each hour. This will be done with only two operators, demonstrating one of the advantages of the system.

COBOD CEO Henrik Lund-Nielsen said:

“The BOD2 is a very flexible printer. For this print PERI has chosen to use a long printer, whereas we used a much shorter but taller printer for printing of the 10m tower for GE. This was the whole idea behind the modular design of the BDO2 printer – it is always possible to find a size that meets the customers need.”

Here you can see a short video of the construction in progress:

COBOD Commercial Construction

There are a couple of things to note with this project.

First, this is not an experiment; it is in fact a true commercial project undertaken by PERI Group. The intention is for actual humans to ultimately rent out the apartments, as they would on any normal construction project.

That’s quite a bit different from almost all of the 3D printed construction projects we’ve seen. Most are demonstrations of a technology and have little commercial viability. This is quite different.

Secondly, it’s important to point out that the BOD2 machine is NOT “3D printing a house”. It is a concrete machine that is specifically building the walls only. As you can see in this image, the concrete walls are produced with a gap that presumably allows for insulative material to be applied.

The remainder of the construction will presumably be done in the conventional manner. Floors cannot be 3D printed without significant supports (formworks in this case), but according to the information we received from COBOD only the walls will be 3D printed.

Other construction steps, such as HVAC, plumbing, electrical, flooring, finishing, etc, will also be built with conventional approaches.

Innovation and Marketing Director at PERI GmbH, Thomas Imbacher said:

“We are very confident, that 3D construction printing will become increasingly important in certain market segments over the coming years and has considerable potential. By printing the first apartment building on-site, we are demonstrating that this new technology can also be used to print large scale dwellings units. In terms of 3D construction printing, we are opening up additional areas of application on an entirely new level.”

With this development it may be that the demonstration is really about the financial viability of such projects. If it passes the test, we could see many more 3D printed buildings in the future.

Via COBOD