MakerBot announced “Clean Air”, a smart filtration accessory for their METHOD X 3D printers.

Why filtration? Most 3D printers operate without any form of filtration, and many don’t even have enclosures. The reason for filtration is due to how FFF 3D printers heat polymers to their glass transition temperature.

This process releases two types of negative emissions, VOCs and nanoparticles. VOCs, or “volatile organic compounds”, are chemicals that can have toxic or irritative properties. Nanoparticles are extremely tiny particles that are so small they rise on heat currents and enter the atmosphere.

In other words, FFF 3D printers tend to emit various quantities of VOCs and nanoparticles into nearby air, where they could potentially be inhaled. Inhaled VOCs can cause a variety of afflictions, while inhaled nanoparticles effectively place a chunk of polymer material inside your body for a very long time, causing other issues depending on the type of material used.

The best solution for avoiding VOCs and nanoparticles is to simply ventilate the 3D printer room. By blasting the air outdoors and replacing with fresh air, you should be clean.

However, installing ventilation is not always feasible. There are installations where, for one reason or another, it’s not possible to install a proper ventilation system.

For those sites the usual solution is to purchase a third party fume extractor, which when attached to the 3D printer will catch most of the bad stuff before it enters the general room atmosphere.

MakerBot has recognized these issues and has prepared a special new accessory for their METHOD line called “Clean Air”. They explain:

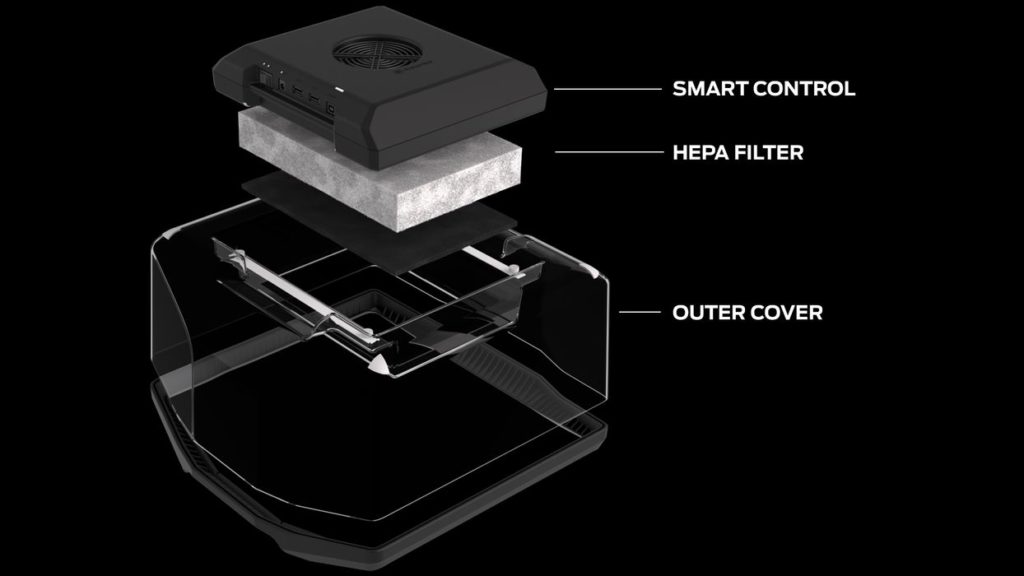

“The MakerBot Clean Air System is a smart-controlled HEPA filtration system for the MakerBot METHOD and MakerBot METHOD X 3D printers. The MakerBot Clean Air System includes a HEPA filter designed to filter ultra-fine particles during the printing process. Internal testing at MakerBot shows that the MakerBot Clean Air System removes up to 95% of ultra-fine particles compared to printing without the accessory. The system seamlessly integrates into METHOD’s intuitive workflow by automatically controlling the HEPA lid and accounting for ambient conditions, chamber temperature, and model material.”

The Clean Air system is more sophisticated than a simple filter and fan as is installed in some systems. Instead it leverages its knowledge of the activity in the 3D printer to adjust its operation. They don’t say explicitly, but it likely operates at a higher level for materials (like ABS) that are known to emit more VOCs and nanoparticles than other materials (like PLA). That should save a bit of energy during long 3D print jobs.

MakerBot CEO Nadav Goshen said:

“We are committed to being world-class in safety as we advance 3D printing’s use worldwide. From meeting industry certifications to delivering 3D printing solutions that support safety, our goal is always to exceed global industry benchmarks.”

This accessory aligns well with MakerBot’s focus on the educational market. While it’s certainly necessary to protect students and teachers as much as possible, the presence of Clean Air could enable more sales. Some educational markets may insist on equipment being equipped with safety features like Clean Air before being allowed to bid on acquisitions. Its MSRP is US$899.

Clean Air is certainly a great idea, and I’m still wondering why all FFF 3D printers don’t yet have similar safety features.

Via MakerBot