The future of 3D printing could be … insects?

I and many others have growing concerns about the amount of plastic trash being produced by desktop 3D printers. While it is quite amazing to witness objects seemingly appearing out of nowhere, these devices also tend to leave behind a lot of plastic.

That plastic might be from filament scraps, support material, failed spaghetti prints and more. It might even be from successful prints that are no longer required, which frequently happens during iterative product development.

The presence of these plastic objects will eventually lead to micro plastic pollution as they inevitably break down into smaller and smaller pieces. Sometimes this takes place in a landfill, but a worse place is the ocean, where currents can carry the microplastics throughout the food ecosystem.

Because of these fears, some are looking hard for new types of 3D printing materials that are useful and biodegradable. That means that after they are sent to the usual disposal services they will naturally break down into harmless chemicals, unlike today’s mostly-forever 3D print materials.

Several materials are being explored, but there’s a new one that I hadn’t previously heard about: insects.

A new research paper to be presented this week at the fall meeting of the American Chemical Society will explain how they were able to create functional bioplastics from chitin extracted from dead black soldier flies. These flies are used in the farming of larva that are used for animal feed and waste disposal, but large quantities of dead fly bodies result from the process.

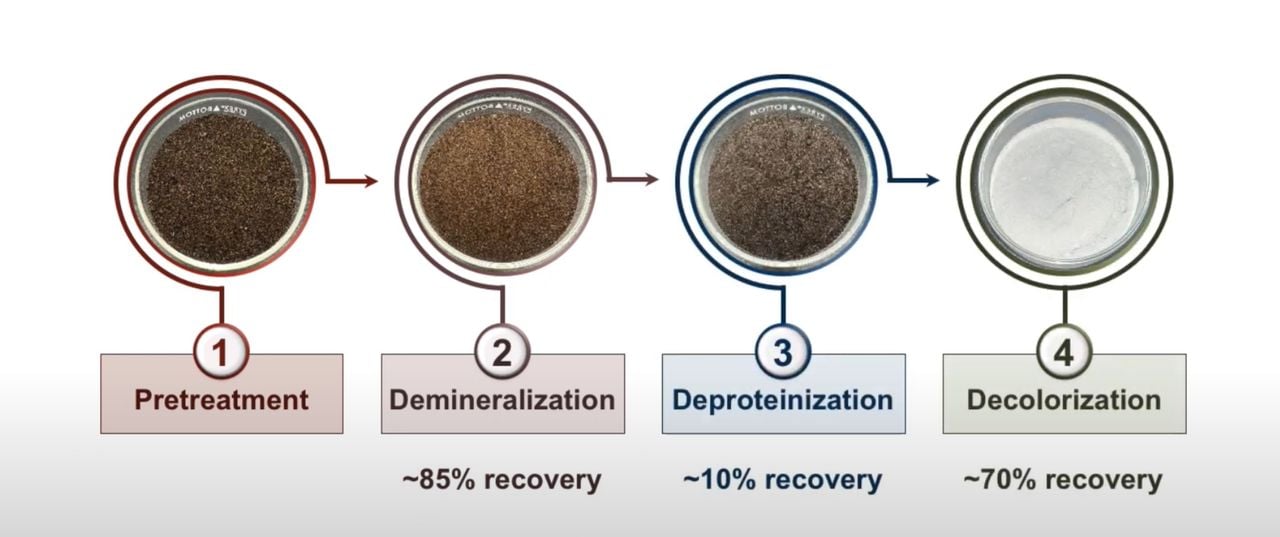

The researchers were able to develop processes to efficiently extract chitin from the fly carcasses, which can then be purified into a polymer they call “chitosan”. This can then be formed into various plastic products, one of which is a highly absorbent hydrogel.

Hydrogel isn’t particularly useful as a 3D printing material, but the same team intends on using chitosan to produce more functional bioplastics that could apparently be similar to polycarbonate, a common 3D print material, and polyurethane, which is often used for casting.

This video explains the process:

All this is merely research, and at quite an early stage, but one can hope that eventually research of this type will stumble upon materials that are indeed practical for use in desktop 3D printers.

If that happens, then there’s far less concern about the endless stream of plastic dragons being produced by these machines.

Via Newswise