Ampower has updated their comprehensive additive manufacturing technology overviews.

The Hamburg-based independent consulting firm provides a variety of services for those in the additive manufacturing industry, including qualification, business strategies, marketing data, business models, training and much more.

One of the services they provide to the industry as a whole is ongoing publication of what must be the most comprehensive infographics of additive technologies anywhere.

Hold on, you may be thinking there really isn’t a need for such data, as there are only a small handful of 3D printing processes, right?

Wrong. It turns out there are a huge number of unique 3D printing processes, with more being developed every month. We are nowhere close to the “end” of this technology, and that’s quite evident when you take a look at Ampower’s charts.

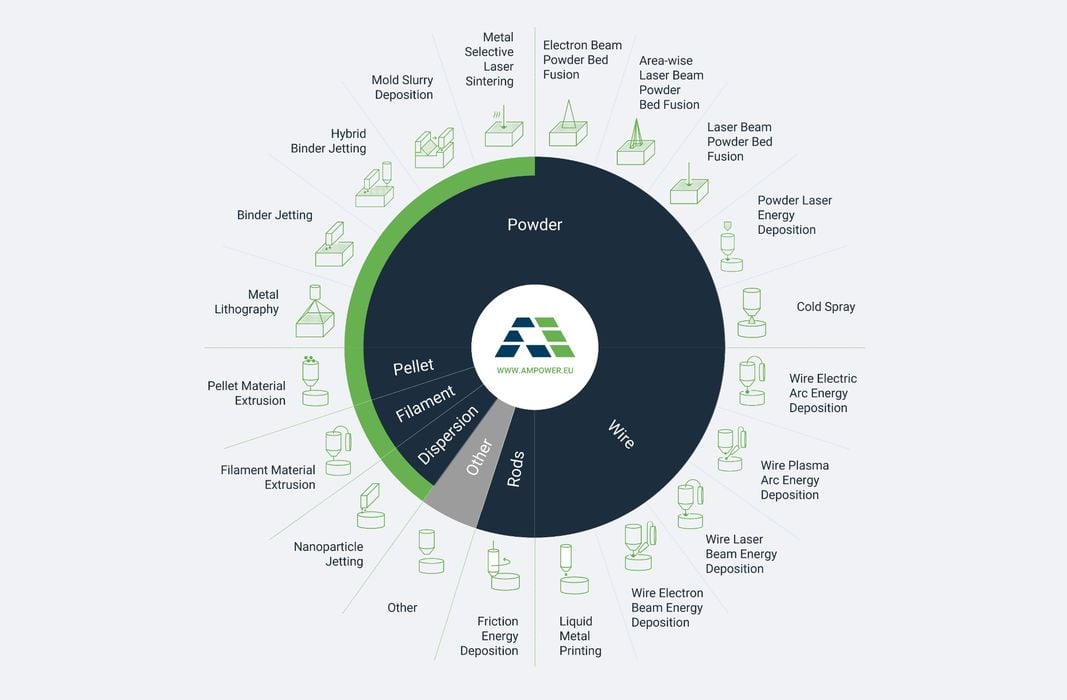

The company publishes two charts, one for metal processes, and the other for polymer processes.

On the metal chart you’ll see familiar 3D printing processes, such as Electron Beam Powder Bed Fusion or Binder Jetting. But there are also many unusual processes you may not have heard of, including Friction Energy Deposition, Wire Plasma Arc Energy Deposition or Liquid Metal Printing.

The latest chart from Ampower shows 18 different metal 3D printing processes, which are grouped into seven categories: powder, wire, pellet, filament, dispersion, rods and “other”.

On the polymer side, 16 different processes are listed in the latest chart. Categories of material are: liquid, sheet, power, tape, filament and pellet. Process include the common FFF and SLA processes, but also unusual approaches such as Elastomer Deposition, Electrophotography Lamination, and Continuous Fiber Sheet Lamination. One technology I’m particularly interested in is Volumetrics Polymerization, which we’ve covered in several stories.

Ampower’s charts also show the currently known vendors of said technologies, which are presented alongside each category.

Some technologies have only a small number (or even only one) vendor. For example, Continuous Fiber Sheet Lamination is performed only by Impossible Objects.

On the other hand, some processes have been adopted by an enormous number of parties. As you might expect, the logo block for FFF companies is a bit crowded:

Ampower does not publish a chart for ceramics as far as I know, but that could be something they develop in the future as an increasing number of ceramic options continue to emerge.

I have seen these charts in printed form, as Ampower often hands out rolled versions at public events. I’m not sure if it’s possible to obtain one directly from the company, but it might be worth contacting them if you are so inclined.

Personally, I would rely on the online version for one simple reason: they change often. As I mentioned earlier, there are dozens of experiments underway in labs around the world attempting to discover new ways to additively build objects. Some of them will show promise and become commercialized.

And eventually they’ll show up on Ampower’s charts.

Via Ampower (Hat tip to Benjamin)