CASTOR announced an amazing new capability: analysis of 2D designs.

CASTOR is a software company that provides analysis of whether CAD designs could or should be 3D printed. This is an increasingly common question among manufacturers, who are slowly turning towards digital inventory strategies.

Digital inventory is the concept where you don’t manufacture all the spare parts in advance while the production line is still running, and store them for years in expensive warehouses. Instead, a digital inventory merely keeps the digital designs ready for 3D printing on demand when required. A properly configured digital inventory could save massive expenses in some scenarios, particularly where parts change constantly, yet spares must be painted for years — or even decades.

But the enthusiasm around digital inventory quickly cools when manufacturers realize they don’t have 3D models for their parts. 3D models are a relatively recent thing, and there have been plenty of designs still in use today that were created in prior eras.

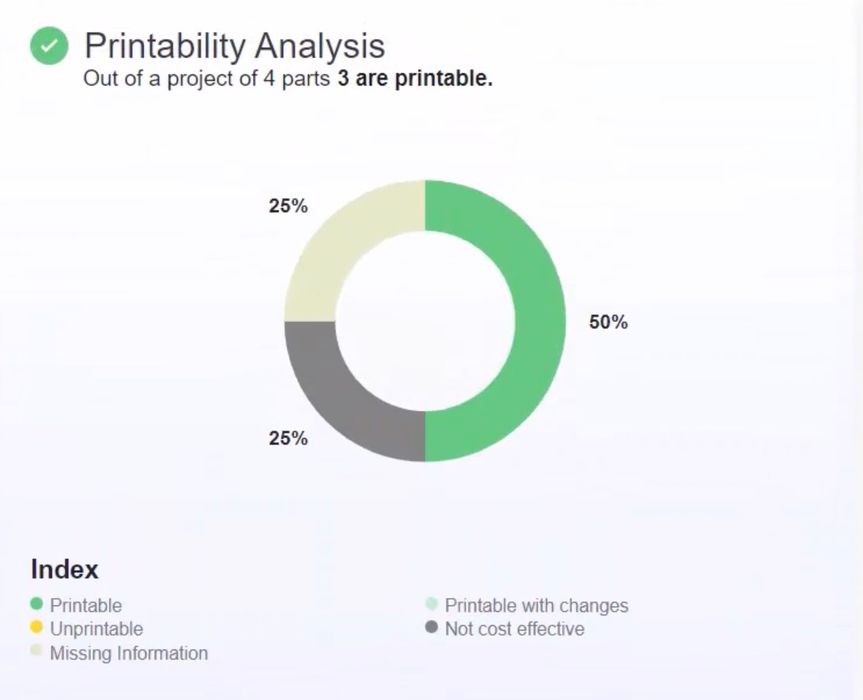

CASTOR’s service can breeze through an inventory of 3D models and provide sophisticated estimates for the cost of production for them, and even determine if they are 3D printable at all. This type of analysis is usually the first step towards a digital inventory.

However, manufacturers will inevitably discover that:

- Only a portion of their designs have proper 3D models

- Many designs will be made with 2D design practices, not 3D (e.g. blueprints)

- Some designs won’t have ANY documentation whatsoever

There’s not much you can do about that last one, but the second problem is one that CASTOR seems to have solved. They explain:

“Now, with CASTOR’s new technology, automatic parts identification for 3D printing is possible using designs’ 2D drawings, even when 3D CAD files are not at reach.

The new capability solves a problem many companies face, especially if they rely on 2D drawings that are decades old, making it difficult and time-consuming to determine which of their parts could be 3D printed.”

How on Earth can this be done? It’s through the magic of machine learning, where CASTOR has apparently trained an AI to examine 2D drawings and interpret each part’s geometry. I’m not certain it literally generates a 3D model, but evidently it inferences enough information to perform the 3D print viability analyses.

The best part is that it’s all automated. CASTOR explains:

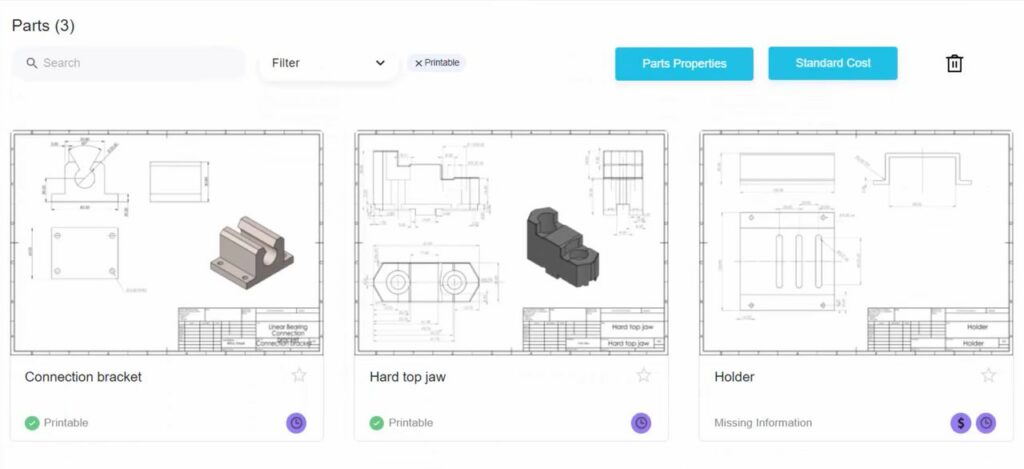

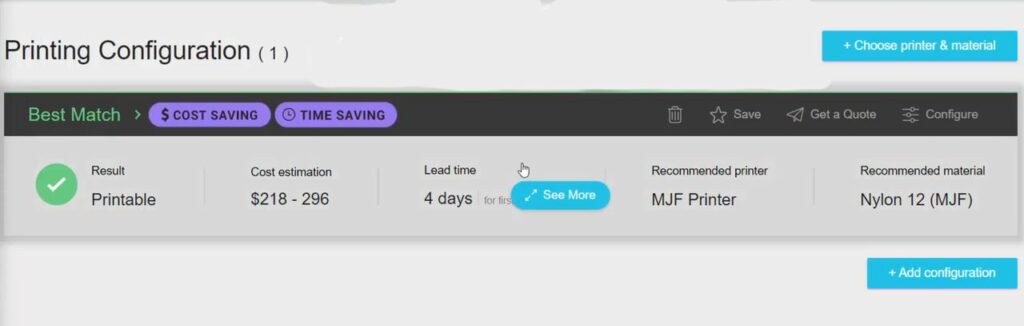

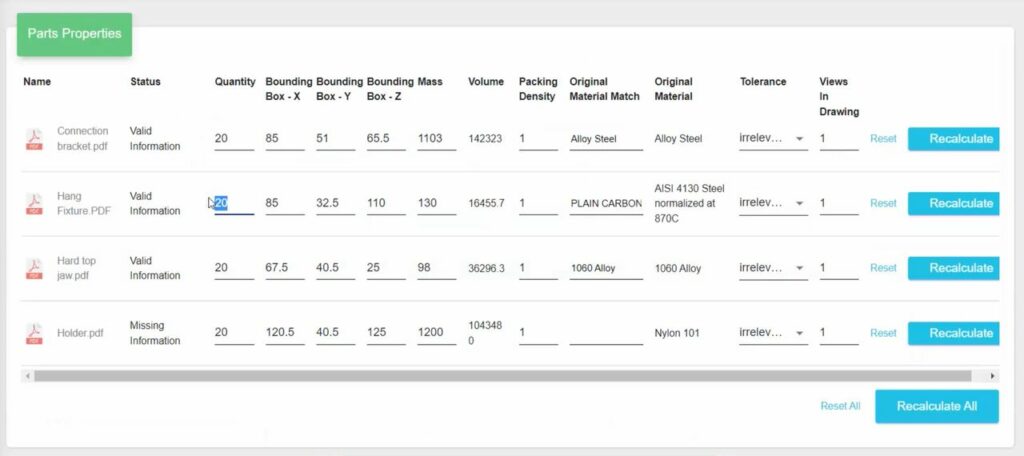

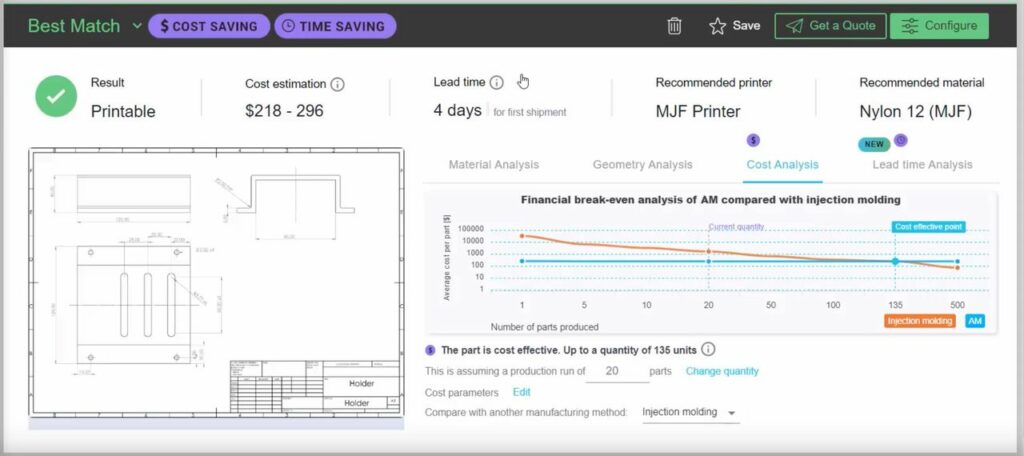

”CASTOR’s software enables to upload thousands of parts from 2D drawings at once. Once parts are uploaded it automatically extracts PMI (product manufacturing information) out of PDF files of 2D Drawings and calculates parts’ size, volume, complexity etc., based on dimensions from projected views. It then suggests 3D printability of parts, recommends optimal technology and materials, and performs a financial analysis of Additive Manufacturing compared to Traditional Manufacturing. It exports useful information and insights, both as a formal PDF report and a raw data excel sheet.”

The results are quite interesting. Here we can see the parts identified in a typical set of 2D blueprints, and you’re able to configure key manufacturing parameters, like quantity, material type, etc., to reevaluate the 3D printing scenario.

This is quite a development that should enable CASTOR to provide service to more companies that are dominated with 2D design files. Some of these organizations may very well have dismissed use of additive manufacturing due to their 2D files, but now they should reconsider.

I’m wondering if CASTOR is also working on the third problem of not having any design files. Perhaps we’ll see that in a future announcement from them.

Via CASTOR