Charles R. Goulding and Preeti Sulibhavi take a look at companies like Cargill and other startups taking on 3D printed plant protein.

The demand for unprocessed, non-GMO, protein-based food is growing at a rapid rate. That, combined with the global population expanding at an alarming rate, has led to the success of companies like Cargill, a maker of foods, provider of financial services, and agricultural products working towards a way to feed the world responsibly by reducing environmental impact and improving lives in different communities.

We have covered 3D printing salmon, 3D printing steak, and even 3D printing plastic food models on Fabbaloo. But Cargill is making a tremendous impact in the plant-based food industry. In 2022 alone, Cargill had US$165B in sales, and it is the largest privately held company in the US. Cargill produces a variety of branded and private-label meats and food ingredients and now offers a wide range of agriculture-related products and services. It is disrupting the Beyond Meat and Impossible Foods market share.

Cocuus

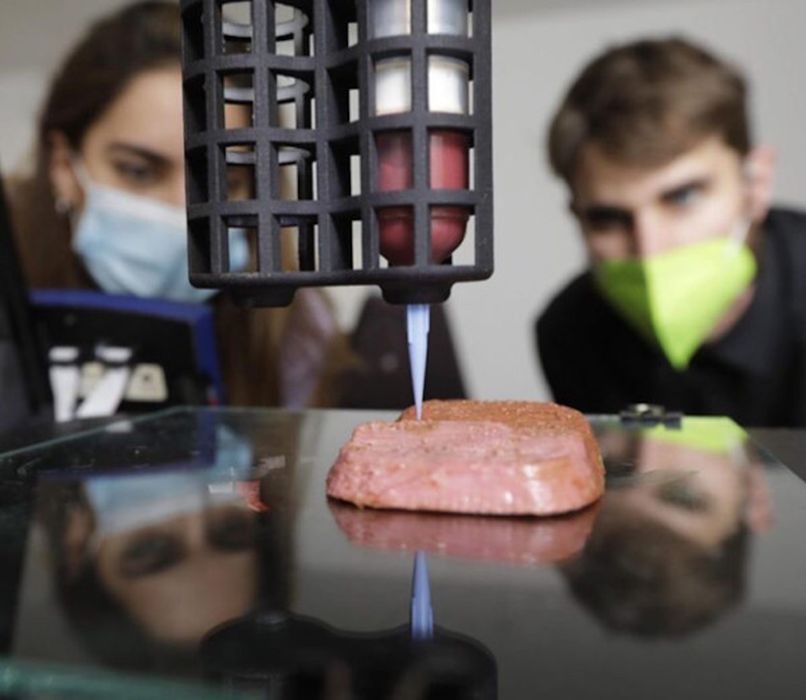

Recently, Cargill became a shareholder of Cocuus, a Spanish startup company that specializes in developing industrial solutions for the production of plant- or cell-based animal protein analogs. After a US$2.8M funding round, Cocuus is advancing its technology.

Cocuus reports that it can print cutlets, bacon, lamb ribs, and salmon at a rate of 8 kilograms per minute, without the slaughter of any animals. The startup has been selected as a finalist for the first edition of Spain Foodtech, supported by the National Center for Technology and Food Safety (CNTA) and ICEX Spain Export and Investment. Cargill has taken notice.

Cargill and Cocuus have collaborated to 3D print food in sustainable and nutritious ways. Many companies in the food industry are able to print a broad variety of foods as we have demonstrated.

Patxi Larumbe, CEO and founder of Cocuus, said, “We are very proud to have attracted the interest of international investors with this round of financing. Thanks to this capital injection we will be able to bring our technology within reach of corporations that want to print proteins on an industrial scale,” in reference to Cargill.

In 2022, Cargill launched its “PlantEver” brand in Thailand. PlantEver offers high-quality, healthy meat alternatives for families on the go. PlantEver offers a healthy alternative to health-conscious consumers.

With an impressive growth rate of 10% per year in the next 3-5 years, the plant-based food industry is expanding exponentially. PlantEver, offers the taste, texture, and nutritional value that health-conscious consumers expect. PlantEver comes in 100% recyclable packaging, so it is handling sustainability issues as well. Its available products are Plant-Based nuggets and Plant-Based meatballs.

Cargill is in the industry for the long haul, judging that the plant-based meats on the market today aren’t satiating enough consumers and dedicating resources to innovate the category. “Cargill is one the few companies that is making the investments and partnering with outside companies to develop a portfolio,” said John Baumgartner, managing director of equity research at Mizuho Securities USA, who follows the plant-based meat industry.

A number of executives at other traditional meat companies believe that plant protein is a fad. Cargill is using this lack of interest to invest for the long term.

Novameat

Alternative meat startup, Novameat, has created the world’s largest piece of cell-based, whole-cut, meat analog. The Barcelona-based plant-based food company is utilizing 3D printers to create hybrid meat analogs using a biocompatible plant-based, large-scale scaffold with a volume of 22,500 mm3.

Other Considerations

There are also food safety concerns to take into account. There may be new allergens that result from certain plant-based meat products or even contaminants with repeated consumption of new proteins. If the plant-based meat product is highly processed, then there may be foreign materials to consider and be cautious about. And, there are of course, dietary concerns in terms of meeting nutritional standards.

A series of stringent quality assurance and controls must be adhered to. Including engineering and administrative controls of all processes.

In terms of “food ink,” plant-based materials are compatible with 3D printers and can produce high-quality results in little time.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There is a reason why Cargill has a 158-year history and is the largest privately held company in the US. It has the courage of its convictions and is experimenting with 3D printing innovative technologies.