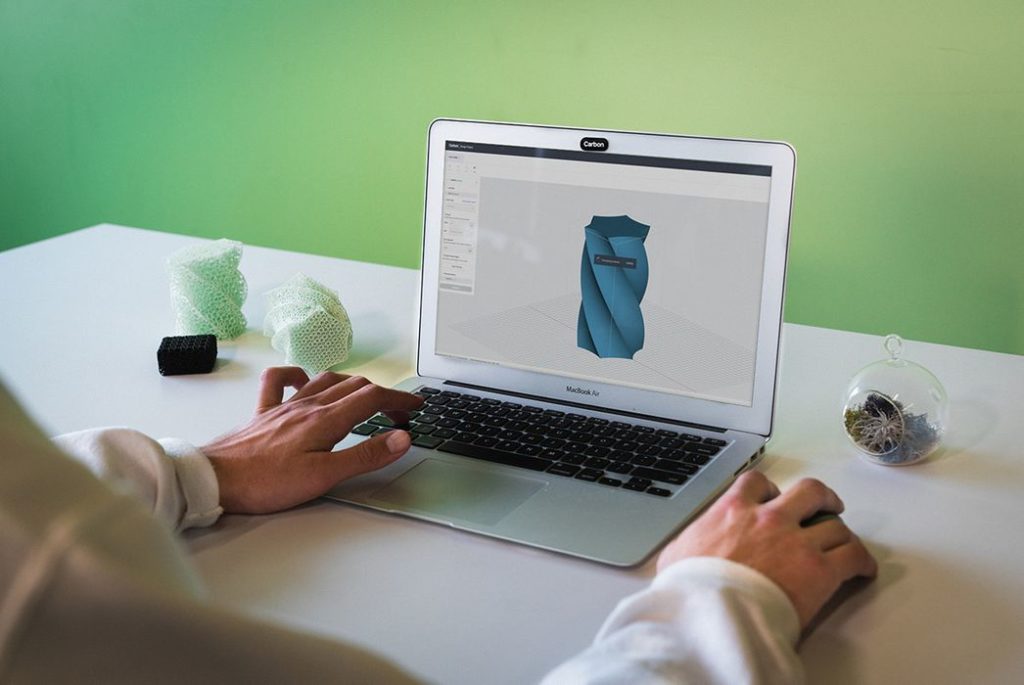

Carbon announced a major move in the software market: they will provide licenses to use their powerful Design Engine tool for anyone, even if they are not a Carbon customer.

This is an extremely interesting move, because the company has largely been built on the ability to design and 3D print complex lattice structures for industry. It was a great strategy, as it allowed Carbon to much more easily work with product manufacturers who struggled with how to do additive manufacturing: give them a tool that let them easily design complex, 3D printable objects.

That tool is Carbon’s Design Engine, which up to now has been exclusively usable by Carbon clients.

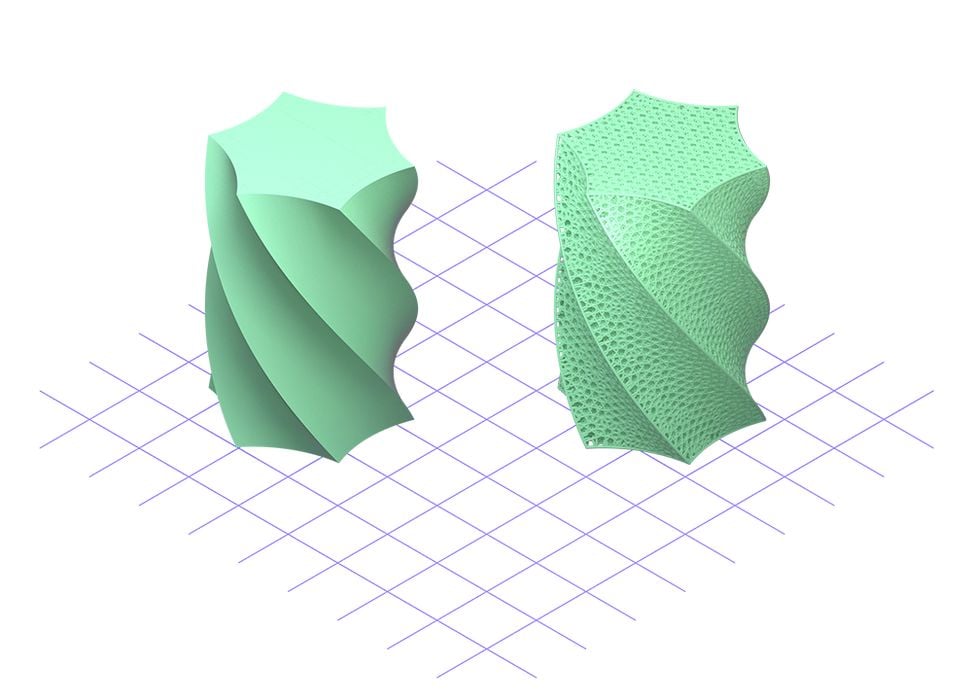

This tool vastly simplifies the extremely tedious and complex matter of creating custom lattice structures in a 3D model.

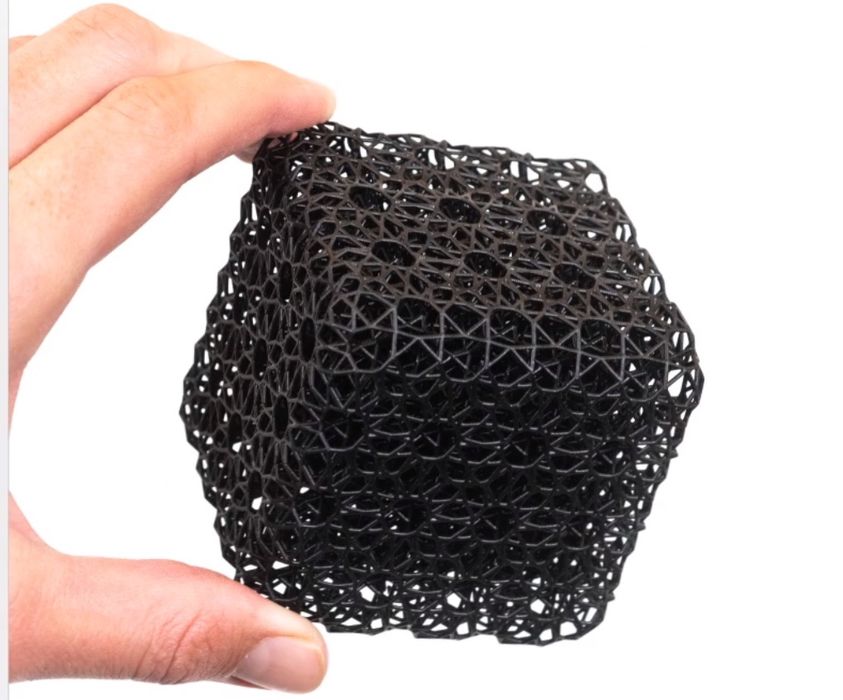

Lattice structures are critical because they enable the production of an object that may have different physical properties: a lattice can bend to absorb an impact, for example, even though the base material used to build the lattice may not.

But consider this: lattices with different styles and densities can provide different physical properties. A smart manufacturer could design, say, a shoe that has multiple lattice styles to match the expected forces in each region of the shoe. And it’s not just forces: lattices allow for the movement of air or fluid, opening up all kinds of design possibilities.

But using standard 3D CAD tools, such a 3D model would be essentially impossible to build. Instead, Carbon lit up their clients by providing Design Engine, which makes it easy to design these complex structures. Carbon listed these features for Design Engine:

- Multi-zone: The Pro tier of Design Engine introduces the ability to tune multiple zones at once, integrating different lattice types, cell sizes, or strut diameters to create different zones of performance within a single part, using the same material.

- Powerful zone transitions: The Pro tier of Design Engine uses patent-pending technology to seamlessly blend zones, producing attractive, functional lattices ready to use in real-world applications.

- No tedious tuning: Designing even simple lattices often requires tedious, manual work that is prone to errors that can significantly impact part performance. Design Engine resolves lattice features, both large and small, while robustly transitioning seamlessly between different zones inside the same part for maximum performance.

- Precise control: Lattices generated in Design Engine can be optimized for a wide array of performance characteristics, including part volume and tunable mechanical response.

- Compatibility: Design Engine is compatible with most part fabrication techniques, outputting generated lattices in the STL file format.

All Carbon clients have been using this tool for years to develop these complex products, and we’ve seen some of them in the public eye, such as the Specialized bike saddle. The tool allows these complex designs to be produced in hours instead of days.

Design Engine performance is pretty incredible. It can take a solid structure and transform it into a “latticed” equivalent in only seconds. This power can significantly speed up development time for those designing advanced products.

Now Carbon has decided to make this powerful tool available to anyone, even if they are not Carbon clients. The idea is to increase the use of 3D printing in general. Carbon’s Phil DeSimone told us:

“More 3D printed products are coming to the space. It’s not about making a 3D printed part, it’s about making a new kind of part that could not be made elsewhere. The goal is to get more people in the space designing better products. Parts created by Design Engine are actually manufacturable.”

Design Engine will be able to produce complex lattice 3D models for printing on any 3D printer, even FFF devices.

Carbon said the product will be available as cloud service and they will have several tiers of access based on slightly different functionality. When asked why use a cloud approach, they explained that they feel its more scalable and affordable than the GPU approach used by other lattice tools.

Carbon has had a huge success by leveraging Design Tool with their clients. Now we’ll see how they will succeed with others using this tool. Kudos to Carbon for pushing this amazing tool out to the larger world of 3D printing.

Via Carbon