A fascinating experiment at the Historical Museum of the City of San Francisco in Argentina showed it’s possible to obtain high quality 3D scans through glass.

3D scanning is always a tricky matter, as the subjects can be incompatible with the scanning technology. And, of course, the subjects can move away from you, if you happen to be trying to scan your pet. Some firm advice: don’t try to scan your pet.

Typical issues with 3D scanning are related to reflectivity. Most active 3D scanning systems involve some form of energy emission, such as from a laser or structured light pattern. While these work very well on “dull” subjects, they can get confused with reflective objects.

The problem is that reflections are interpreted literally by the scanning software and generally mess up the 3D scan, sometimes terribly so.

Scanning reflective objects often requires special attention. A shiny metal part, for example, would have to be coated with some kind of non-reflective substance in order for most scans to work at all. In fact, this is so necessary there are now specialized sprays that can coat a subject in an opaque material that evaporates away over time.

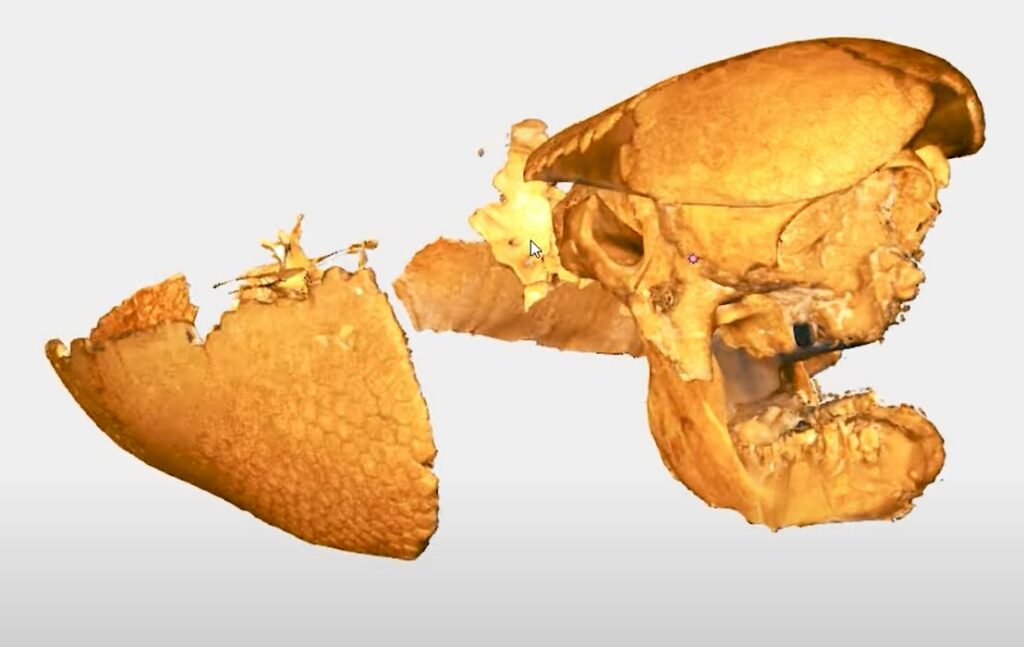

The museum was interested in obtaining a scan of a fossil from the area of an armadillo-like creature from prehistory, the Neosclerocalyptus.

Normally, this would be a straightforward scan, but the requirement here was to leave the fossil in its normal display case — surrounded by reflective glass.

Could this work? 3D scanning specialists at Disegno Soft attempted to perform the scan with an Artec Leo handheld 3D scanner from Artec 3D.

The Artec Leo is a very capable 3D scanner, and we performed a detailed evaluation and review of the device in 2021. Since then, Artec 3D has actually upgraded the device and it’s now even more powerful than the version we tested.

It turns out the Artec Leo was able to successfully peer through the glass and obtain an excellent 3D capture of the Neosclerocalyptus fossil. Evidently the scan process itself took only 20 minutes, while subsequent processing into a 3D model in Artec Studio 16 took about four hours total.

If I were attempting this scan, I’d try to remove any external lighting, while keeping the lights on inside the glass case. That should eliminate most of the reflections. However, as you can see in this video (en español), it appears that the lighting was “normal”, and somehow the Artec Leo was able to see through the inevitable glass reflections. My suspicion is that the scanning process involved very carefully orienting the scanner to avoid perpendicular views of any glass surface.

The result was quite good, as you can see in this image.

This demonstration is quite useful in that it clearly shows that it is possible to obtain scans even in supposedly difficult conditions — that is, if you use the right equipment with proper procedures.

Via Artec 3D

D.I. Macarena Garat