Jason Pohl and how xShape has changed his world of industrial design.

xShape offers a new way to make shapes as well as a way to make organic shapes. Organic shapes—those that are smooth, rounded and irregular—are the norm in nature but are avoided by CAD users because making them with CAD programs is almost impossible. It helps to be a wizard with surfaces, but few CAD users are.

It’s Not Natural

Nature is complicated, whereas all solid modeling shapes are made from combinations of simple shapes: rectangular solids, spheres, extrusions and the like. Sure, with enough simple shapes and time, you could eventually make Michelangelo’s David. In the manner of all professionals who make their art look simple, the artist is purported to have said that all he had to do was chip away all of the Carrara marble that didn’t look like David. A 3D model could be made by subtracting from a rectangular solid, with big chunks first and then smaller and smaller chips, the features getting more refined over time. Lots of time.

Streamline Moderne

CAD veterans will ask, Why even try to make organic shapes? What’s wrong with perfectly straight, round and flat ones? Is that not an improvement over nature? Why copy nature when you can improve upon it? Is it just for art?

Some organic shapes are made for purely aesthetic reasons or to satisfy the fashion of the times. This happened in the 1930s when the advent of commercial aircraft led to streamlining everything. Streamlining cars and locomotive engines may have had some justification, but the Streamline Moderne movement also shaped stationary objects such as toasters and bus stations.

But there are also very practical reasons to create organic shapes and the best are found in the interface of ourselves and the things we create. This is where our hands meet our tools, our bottoms meet seats and shoes meet our feet. At this interface, natural shapes meet man-made shapes, soft meets hard, round meets flat, and so on.

Here lives the industrial designer, that blend of artist and design engineer, and the study of ergonomics, which comes from the Greek “ergon” for work and “nomos” for natural laws. Industrial designers have flailed at ergonomic designs of tools, containers, furniture, and so on with CAD tools but gave up. Who has the time to chip away at blocks? A few design tools have evolved for their purpose—those that use splines rather than lines, the foremost and favored being Rhino 3D by Robert McNeel & Associates. Rhino has found a niche with architects as well in making conceptual models. But for the most part, Rhino has not entered the mechanical design mainstream.

Enter xShape

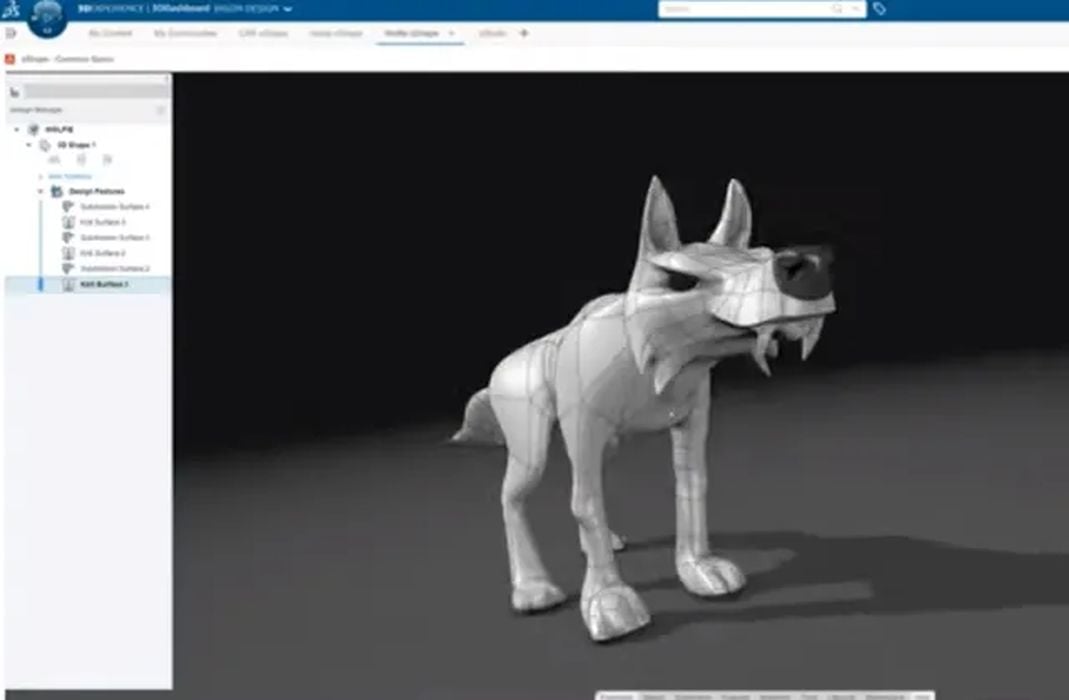

Dassault Systèmes hopes its entry into organic modeling, xShape, will change all that.

Available as part of the company’s 3D Sculptor “role,” xShape uses subdivisional modeling, or sub-D, instead of the Parasolid geometry engine used in mainstream MCAD applications, like SOLIDWORKS and Solid Edge.

Using xShape is literally child’s play. You start with a slightly rounded cube and you pick and poke at it until you get the shape you want. Pull out a point in the middle of one face to start a nose, for example, and points on adjoining faces that will be fashioned into ears. They are just lumps at first, but you can zoom in to add detail with ever-smaller picks and pokes. xShape uses symmetry planes so that any tweaks on one ear are reflected in the other. The surface seems to be able to add enough splines to support the next level of detail. There’s no apparent limit to the level of detail and you may have to tear yourself away. Do you really need to show the pores on David’s skin?

Read the rest of this story at ENGINEERING.com