Charles Goulding Jr. examines the new US initiative to Build Back Better and how the 3D printing industry is set for a major role.

Long Overdue

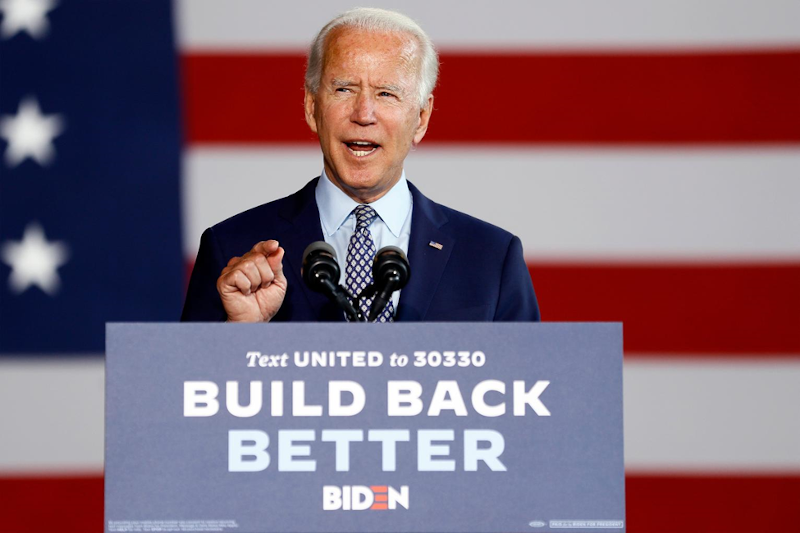

In the coming week, US President Biden is expected to unveil more details of his Build Back Better infrastructure plan, a set of reforms believed to total more than $3 trillion in new investment. The plan is long overdue. For decades, politicians have paid lip service to infrastructure as America’s roads, bridges, and railways have languished. Now, the stars may have finally aligned for a unified House, Senate and Chief Executive to take action.

The Biden approach is believed to be broad in scope, addressing topics as wide-ranged as climate change and health care.

If the plan proceeds, infusions of capital may impact a host of fields that involve 3D printing.

Climate Change

President Biden’s commitment to climate action is clear — one of his first executive actions was to reaffirm the United States’ commitment to the Paris Climate Accords.

As the carbon clock ticks toward 400 carbon dioxide parts per million, meanwhile, it seems more and more necessary to embrace the widest possible range of solutions. Bill Gates reiterated that view last week when he stated on Reddit that “we must be open to ideas that seem wild.”

One of the wildest ideas, carbon capture, has been endorsed by Gates and others. In Direct Air Capture (DAC), the biggest moonshot of all, large fans literally inhale air which is then filtered of its CO2 content.

As reported here, researchers have used 3D printing to innovate ways to make DAC more efficient.

Another, more traditional way 3D printing will likely partake in the Build Back Better clean energy revolution? Wind turbines.

Decarbonized Power Generation

President Biden intends to “Move ambitiously to generate clean, American-made electricity to achieve a carbon pollution-free power sector by 2035. This will enable us to meet the existential threat of climate change…”

One way to decarbonize power plants is through another type of carbon capture — point-service. Here, carbon is captured at the very point of emission and then sequestered.

As detailed here, recent innovations from 3D printing have enhanced the cooling devices necessary to efficiently complete the CO2 absorption process.

Housing

President Biden has aggressive goals for the future of housing. In particular, his plan will “spur the construction of 1.5 million sustainable homes and housing units.”

The timing of the housing plan is perfect for 3D printing. Already this year, the 3D printing industry has printed new housing in Long Island, Austin, and Rancho Mirage.

In fact, just this week, Tim Shea became the first person to officially move into one such home, in Austin’s Community First! Village.

These 3D printed homes boast key advantages that dovetail perfectly with Build Better Better objectives. Those advantages are cost, time of construction, and sustainability. Indeed, estimates of the cost for a 3D printed home range from 25-50% of the cost of traditional construction.

Further, the Rancho Mirage development, set to open this summer, is especially noteworthy for its eco-friendliness. The printed homes use an innovative Light Stone Material purported to be lighter than concrete. Further, each home uses a Tesla solar wall for all necessary power generation.

These 3D printed residences may be the perfect solution to help meet President Biden’s residential goals.

Construction

For President Biden, Building Back Better doesn’t just mean new homes — it means upgrading the nation’s entire building stock, from schools to office buildings to everything in between.

Some of 3D printing’s newest and most promising construction firms have been reported here. Of particular note is the way these and other 3D printing firms now work with innovative concrete. One such example: the Bruil/3Dealise partnership.

Transportation

It may be a while before 3D printing can assist with major bridgeways or other means of transportation. Nonetheless, it’s worth noting that in the past few years, a number of footbridges have been constructed with significant help from 3D printing.

First came a bridge in the Netherlands, then a group in China. The U.S. Marine Corps even uses 3D printing to make concrete footbridges. The 3D printing approach could potentially be useful in creating custom, sustainable footbridges as part of urban greening goals.

Supply Chain Strengthening

Supply chain disruptions can be devastating. Just ask Boeing. In 2007, the firm had bold predictions for its new Dreamliner. But supply issues — including for items as seemingly trivial as fasteners — delayed the project for years. Before the ordeal was over, Boeing was in Home Depot buying parts for its 787 planes.

Supply chain risks have caused the Biden administration to order a special report on U.S. manufacturing and what must be done to strengthen supply chains.

This Executive Order could be crucial to 3D printing. The goal of Biden’s plan is not to on-shore all manufacturing that departed the U.S. over the past few decades. Rather, the goal is to strategically fill potential gaps and ensure that capacity exists when and where needed to withstand shocks.

3D printing, with its ability to quickly produce custom items, is well-suited to supply chain gap-filling — more so by the day as 3D printers become more adept at using metal and other high-quality materials.

To that end, Xerox recently unveiled its new ElemX 3D metal printer, which it believes will help alleviate knotty supply chain issues within the military.

Conclusion

President Biden’s choice to take on infrastructure before other pressing policy concerns is significant. The success of the Build Back Better program will consequently go a long way toward defining the success of the 46th President’s first term in office. With a price tag between $3 and $4 trillion, there will be a lot of investment in a broad range of industries. 3D printing touches on many of these fields and will likely play a role in the country’s rapid modernization.