Researchers have unveiled a new method of nano-3D printing that addresses current limitations, offering both speed and precision unprecedented in nanomanufacturing.

Background: Nano-3D Printing and MPL

In recent years the power of nano-3D printing to create intricate end-use micro components with nano-scale features has caught the attention of several industries worldwide. The standard technology used in this domain is Multiphoton Lithography (MPL), a 3D nanomanufacturing technology that uses a photopolymer resin / light engine approach.

This technique has been used for many years in the world of micro-optics, photonic crystals, and metamaterials. However, there have been challenges. Current MPL methods, while promising, often fall short in balancing high throughput, design freedom, accuracy, and material versatility.

One of the primary issues is the speed of printing, which is normally quite slow in both projection and laser approaches.

A New Solution

Stepping in to bridge this speed gap is the newly developed acousto-optic scanning with spatial-switching multispots (AOSS) method.

The genius of this approach is twofold. First, it uses acousto-optic scanning in place of traditional inertial mechanical scanning, ramping up the laser scanning speed significantly.

Next, it employs a spatial optical switch, allowing for beams with different scanning angles to be activated or deactivated, offering high resolution not bound by the usual temporal optical switching frequency.

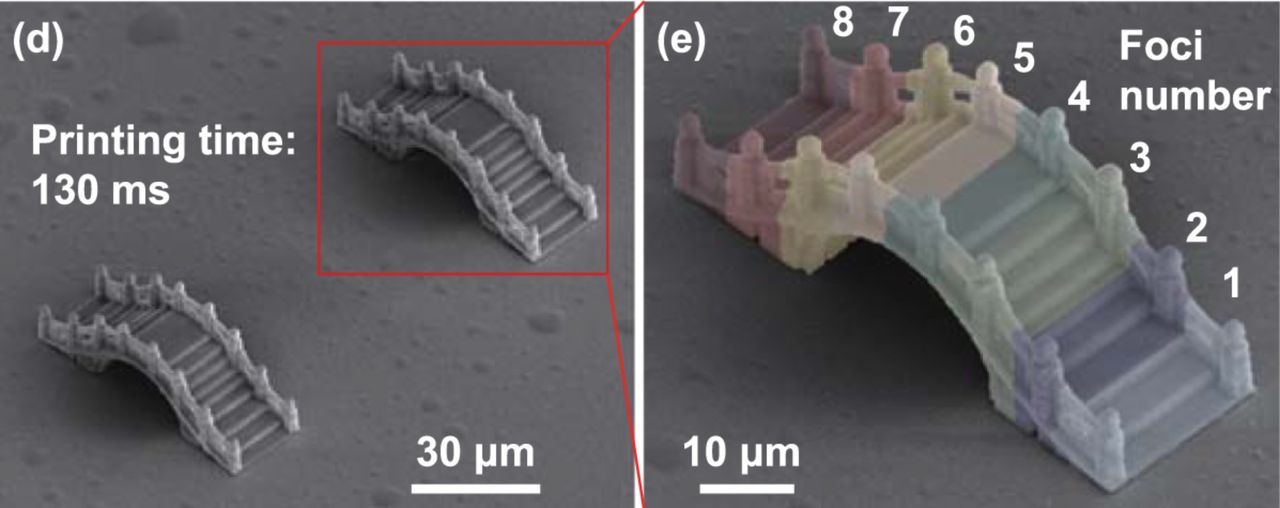

The outcome? A dazzlingly swift single-focus 3D printing rate of 9,500,000 voxels per second. But that’s not all; with parallel scanning, an eight-foci MPL system records a print rate of 76,000,000 voxels per second, outperforming the best of state-of-the-art MPL methods.

Implications of AOSS

The AOSS method’s capacity to marry the best of both scanning and projection MPL methods can change the game for industries reliant on 3D nano-structures. This isn’t merely an incremental improvement; it’s a leap. The results of research testing are 10X faster than those using prior MPL technologies.

With its elevated speed and enhanced design freedom, it’s easy to envision AOSS becoming the go-to technology for producing intricate 3D micro and nanostructures. This can pave the way for innovations in metamaterials, micro-optics, micromechanical devices, and potentially even tissue engineering scaffolds.

However, I remind readers that this is only a research project at this stage, and would have to go through a commercializations process before it would be usable by industry.

Via IOP Science