In a surprise announcement today, Markforged has acquired Teton Simulation.

This is the very first corporate acquisition by Markforged, and it is an extremely strategic and shrewd move by the company.

Markforged, of course, is the well-known producer of metal and high-strength polymer 3D printers, beginning with their continuous carbon fiber solution. Even today, there are very few makers of continuous carbon fiber 3D printers, with Markforged’s solution being one of the top choices.

You’re probably less familiar with Teton Simulation. They’re a software company based in Wyoming, and they produce something called “SmartSlice”.

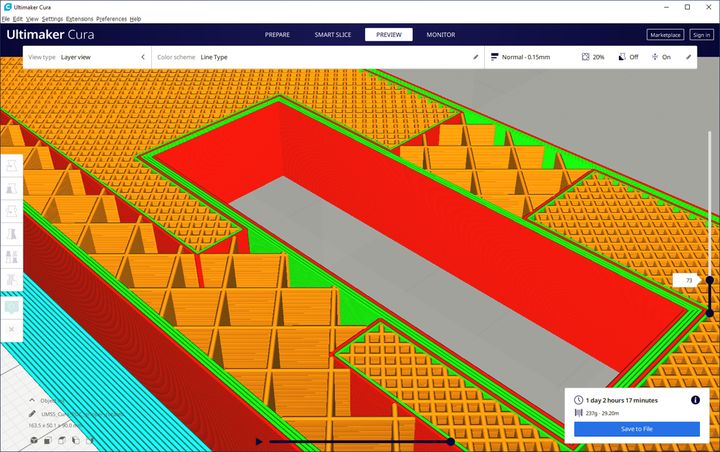

It’s not a 3D print slicer, as the name suggests, but instead is a cloud-based plugin for existing slicing software. What does it do? Well, quite a bit.

Essentially SmartSlice performs a finite element analysis on parts to be prepared for 3D printing, and makes adjustments to the tool path to meet the needs of the analysis.

In other words, if you tell SmartSlice the forces the part is expected to encounter, it will automatically redesign the print extrusion to make the part strong where it needs be. This does not change the exterior of the part, but instead plays with the infill, perimeters and other extrusion variables. For example, infill could be rotated to ensure more strength in a particular direction — and this could be done for multiple regions within the part.

We’ve previously covered SmartSlice and Teton Simulation in much more detail here.

This is far more intelligent than typical slicers that simply repeat an infill pattern over the entire part. And it’s all done automatically, provided the operator provides some input about part requirements.

Markforged intends on integrating SmartSlice into their Digital Forge cloud system, where it will be offered as an optional paid subscription for those requiring this functionality. It will become part of Markforged’s Eiger system. Markforged explains the benefits:

“The acquisition adds strategic functionality to the Digital Forge to give Markforged’s thousands of users confidence that printed parts will perform as intended, enabling them to replace even more end-use metal parts with validated Continuous Fiber Reinforcement (CFR). This addition to Markforged’s software offerings will help customers take the guesswork out of configuring slicing parameters for end-use requirements, knowing they can estimate part performance without the wasteful and slow process of physical testing.”

Neither Markforged nor Teton Simulation provided details of the acquisition’s terms, but you can bet this was an expensive deal for Markforged.

Why? Because Teton Simulation’s SmartSlice is an incredibly powerful tool: it automatically makes all parts much stronger, almost to the theoretical limit of each job.

Now SmartSlice belongs to Markforged.

Previously, Teton Simulation sold SmartSlice by subscription through several other company’s slicing software tools. For example, it is available as a plugin for Ultimaker Cura, where professionals can make stronger parts for any 3D printer usable on Ultimaker Cura. It’s also partnered with Stratasys’ GrabCAD, BCN3D and BigRep.

Those tools would represent quite a few models of 3D printers, maybe all of them.

Markforged did not mention what will happen to these non-Markforged existing plugin subscriptions. It is possible they may discontinue them in the future, making Markforged equipment the only possible way to access the SmartSlice function.

On the other hand, they may continue offering subscriptions to SmartSlice to other parties and continue much as they are doing today.

However, Markforge’s market space is all about making really strong parts. That’s why they got into continuous carbon fiber in the first place. Allowing competitors to make strong parts doesn’t exactly seem like the right approach. But it remains to be seen what will transpire.

For Markforged, this is a tremendous acquisition and will benefit their company for many years to come.

Via Markforged and Teton Simulation