Charles R. Goulding and Matthew Selman look at usage of 3D printing by several major oil & gas companies.

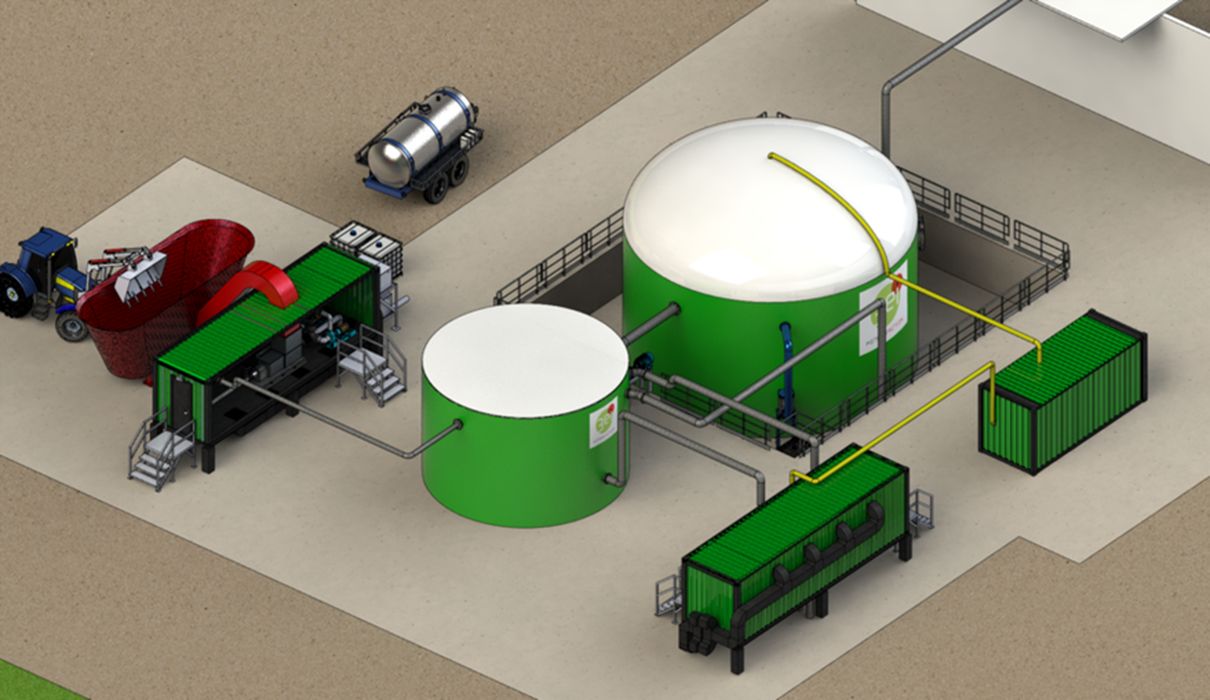

BP, one of the world’s largest oil and gas companies, has agreed to purchase U.S. biogas producer Archaea Energy Inc. for US$3.3B plus debt to accommodate the growing demand for renewable fuel.

Archaea operates 50 renewable natural gas and landfill gas-to-energy plants throughout the U.S. The purchasing of Archaea will instantly increase BP’s existing biogas production by about 50%. BP is shifting more resources into lower-carbon energy to expand its clean-energy portfolio.

A similar trend can also be seen by two large multinational oil and gas companies—ExxonMobil and Shell.

ExxonMobil acquired a stake in the Norwegian biofuel company Biojet AS, while Shell spent about US$2B to acquire Danish biogas producer Nature Energy. There has been a clear increase in low-carbon energy alternatives, specifically biogas, as concerns over the environment have grown.

BP predicts that demand for biogas will grow by about 25 times by 2050. To accommodate the increase in demand, substantially more biogas plants will have to be created and used for production. This trend will not be exclusive to BP however, as it is clear that many oil and gas companies are transitioning to increase biogas production.

3D Printing & Biogas Purification

Biogas is an environmentally friendly renewable energy source that is produced when organic matter is broken down by microorganisms in the absence of oxygen. The biogas product is approximately 60% methane, with the other 40% being comprised of carbon dioxide. The carbon dioxide must be removed before the biogas can be turned into a useful fuel.

Traditional methods of purification include water scrubbing, membrane systems, amine gas treatment, pressure swing absorption, and more. While these methods are possible in themselves, 3D printing presents a more efficient option.

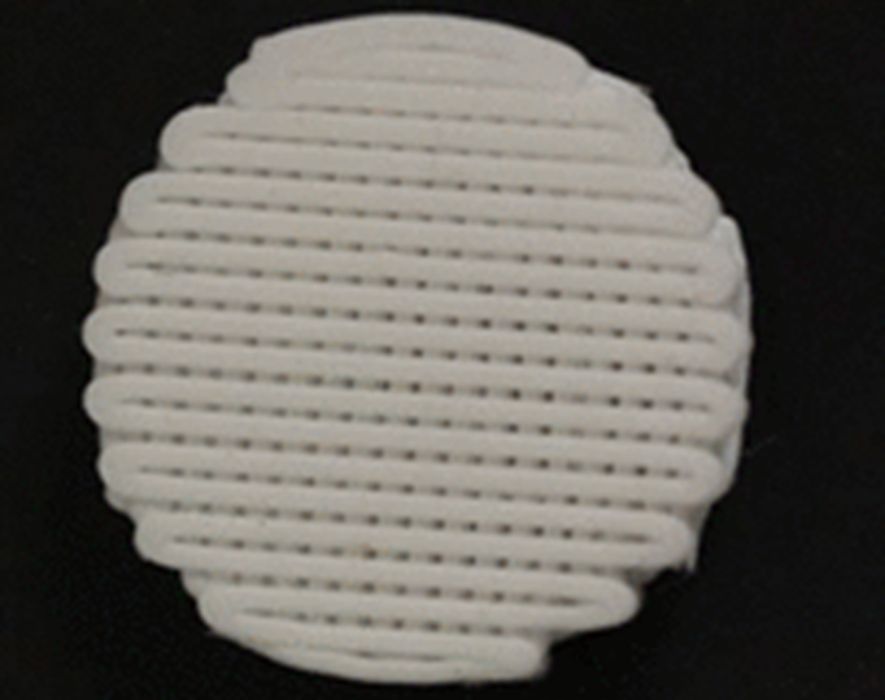

Sarah E. Baker and her group at Lawrence Livermore National Laboratory determined that microcapsules of a sodium carbonate solution encapsulated by silicone could absorb carbon dioxide very efficiently. The problem with this method was the difficulty of large-scale production of the microcapsules.

Instead, they made a composite by blending silicone resin and carbonate powder. The material was then 3D printed into porous sponges with a high surface area. The 3D printed material was low-cost, non-toxic, and water tolerant.

The process of carbon dioxide absorption also used low amounts of energy because it was capable of absorbing the carbon dioxide at close to ambient pressures and temperatures.

The 3D printed carbon-absorbing material, as depicted in the image above, provides an inexpensive and effective method of purifying biogas. 3D printing can also potentially be used to create cost-effective pipes for biogas production plants. As biogas production continues to increase going forward, 3D printing materials can prove to be a valuable tool to assist in the efficient production of biogas.

Inflation Reduction Act Impacting Biogas Production

The recently passed Inflation Reduction Act further incentives the production of biogas for projects complete after December 31st, 2022. The law provides a more stable tax credit incentive to allow biogas to compete with wind and solar more effectively. Previously, projects that used biogas in connection with generating electricity were eligible for an electricity production credit.

While this credit opportunity is still in effect, many additional processes that generate biogas for other purposes have become eligible for federal tax credits, including the sale of renewable natural gas. This monetarily incentivizes oil and gas companies to increase biogas production, and this transition is already evident from the previously mentioned acquisitions.

3D Printing at BP, ExxonMobil & Shell

BP, ExxonMobil, and Shell already utilize 3D printing at their companies and are expected to increase their usage in the future.

At ExxonMobil, new acrylic, metal, ceramic spirals, and other shapes are 3D printed in the company’s advanced 3D printing laboratory. This is very useful for rapid prototyping, as new designs and breakthroughs for advanced energy solutions are typically found with prototyping.

BP has incorporated 3D printing for years as they utilize it to manufacture components and to go straight from concepts to physical models when bringing ideas to life. Shell operates in a similar manner, as they utilize 3D printing to print spare parts on demand, develop novel equipment, and rapidly prototype engineering designs.

3D printing is an important aspect for these large gas and oil companies, and the importance will likely continue to increase going forward.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Biogas production is expected to increase for the foreseeable future because it is a viable, environmentally-friendly, renewable energy source that is also incentivized through the Inflation Reduction Act. Evidence of this is BP’s acquisition of Archaea, ExxonMobil’s acquisition of Biojet AS, and Shell’s acquisition of Nature Energy.

All of these are examples of large oil and gas companies transitioning to increase biogas production. 3D printing can be expected to increase in combination with biogas production. 3D printing provides less expensive alternatives to the industry, such as a 3D printed carbon-absorbing material, that can improve the efficiency of the production plants.

3D printing is also important for rapidly prototyping designs and for manufacturing components. Advancements in 3D printing can also result in more unforeseen advantages relating to clean energy production.