Boston Micro Fabrication is on the move.

“BMF”, based in — you guessed it, Boston — has been quietly growing strongly in several ways.

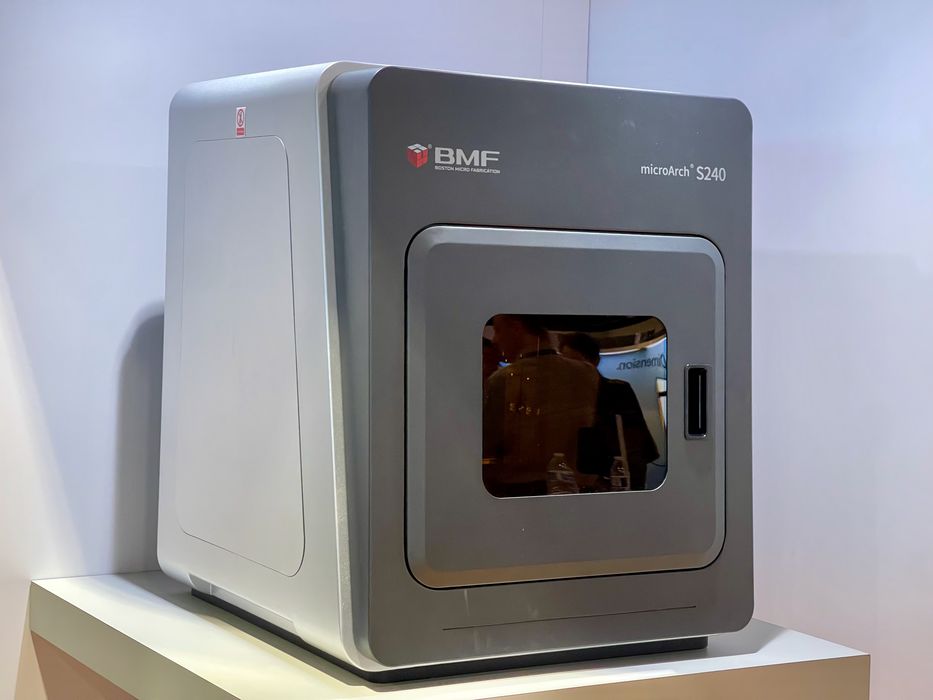

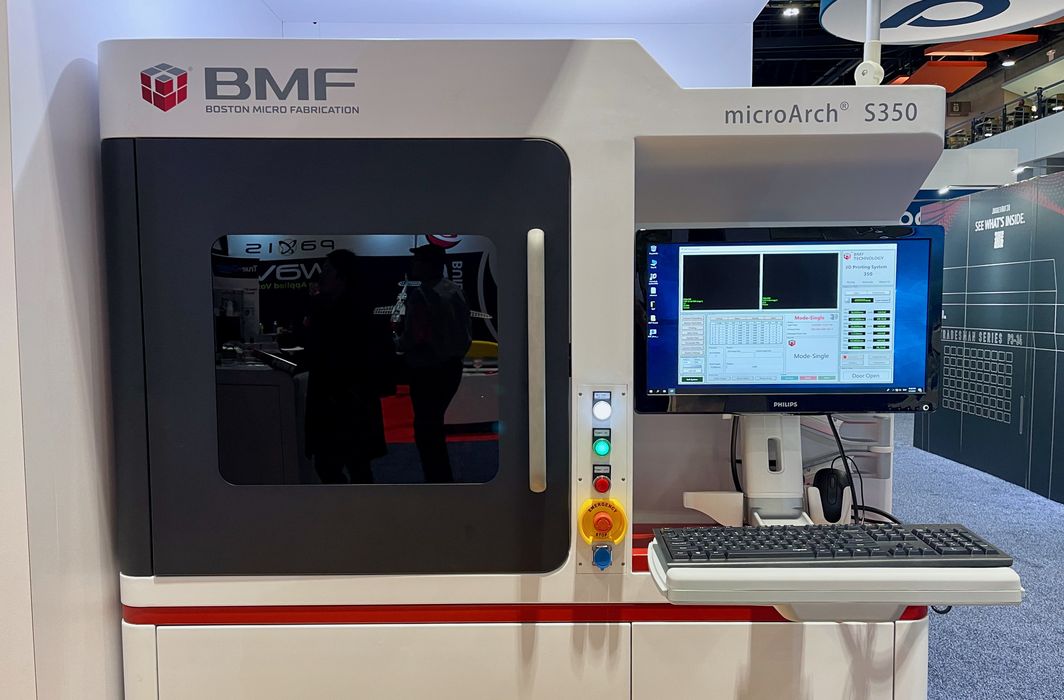

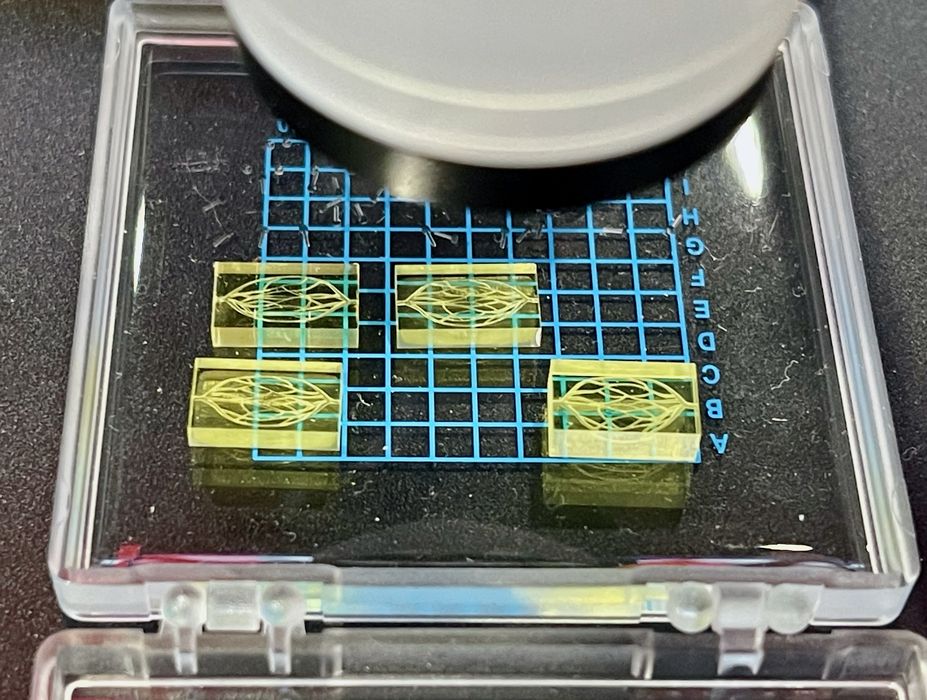

The company produces high-precision micro 3D printing devices used by industry for a variety of applications. They currently offer three lines of equipment, each with a different optical resolution: 0.025mm, 0.010mm and an incredibly small 0.002mm.

While the company focuses on the smallest resolution, their most recent device, the S350, has the “coarsest” resolution of the bunch at 0.025mm. They introduced this model because it turns out many of their customers actually don’t require the highest resolution for some applications, and appreciate the higher throughput provided by the S350.

In a recent conversation, BMF representatives told us they are selling “lots of devices to universities”, where they are presumably being used for research and training purposes. The specific applications include fluidics devices and other microscopic systems.

This week they announced a rather large investment round of US$24M, which is only one year after receiving a massive US$42M Series C investment. According to Crunchbase, the company has now received almost US$80M in total investment over four funding rounds.

This certainly makes BMF one of the most well-capitalized 3D printer manufacturers, and indicates the confidence held in the company by their investors.

This is not surprising, as the area of focus for the company is quite new, with relatively few applications present. It’s quite possible that with BMF equipment researchers and companies may develop new applications previously unseen. That could be why investors see the company growing.

What will BMF do with the new cash? They explain:

“The funding will allow them to develop and incubate new products that are uniquely enabled by high-precision, micro 3D printing and advance global collaborations to spark innovation across industries like medtech and electronics.”

That sounds like new applications to me, doesn’t it?

Via BMF