Charles R. Goulding and Preeti Sulibhavi look at some of the most intriguing metal 3D print companies to emerge from Massachusetts.

Three of the nation’s leading metal 3D printer companies are in the Boston area. Two of the companies namely MarkedForged and Desktop Metal, are famous as pioneers of metal 3D Printing.

MarkedForged

MarkedForged’s platform, The Digital Forge, is an intuitive additive manufacturing (AM) platform powering engineers, designers and manufacturing professionals globally. The Digital Forge combines precise & reliable 3D printers and metal and composite proprietary materials with its cloud-based learning software offering to empower manufacturers to create more resilient and agile supply chains.

Founded in 2013 by two MIT-educated engineers, Markforged is based in greater Boston, Massachusetts, where they have their own in-house manufacturing facility and where engineers design all MarkedForged’s industrial 3D printers, software and metal and composite proprietary materials.

MarkedForged’s customers have printed millions of parts, meeting customer needs across the entire product development lifecycle, including prototyping, tooling, production and aftermarket spares and replacement parts as well as mid-volume and high-volume production parts.

Blue chip customers in leading-edge industries such as aerospace, military and defense, industrial automation, space exploration, healthcare and automotive rely on MarkedForged’s platform for mission-critical, end-use parts on-demand and at the point-of-need.

According to MarkedForged’s SEC filing, 10-K:

“Their portfolio of rugged 3D printers includes: (i) desktop printers that produce quality parts in settings where space is limited, (ii) industrial composite printers that provide powerful, predictable functionality through their software, sensors, materials and print modes and (iii) metal printers that can fabricate strong, complex metal parts in a variety of advanced metals. Across all their models, their powerful yet easy-to-use platform, and their industrial-grade materials, enable engineers to make functional parts for manufacturing environments and other demanding applications.

MarkedForged’s software platform was developed alongside the first 3D printers and shipped as a fully integrated solution.”

Desktop Metal

Desktop Metal is pioneering a new generation of additive manufacturing technologies focused on Additive Manufacturing 2.0, the volume production of end-use parts. The company has grown rapidly by acquiring many leading 3D printing companies, including ExOne, a publicly traded company. They offer a comprehensive portfolio of integrated additive manufacturing solutions comprised of hardware, software, materials, and services with support for metals, polymers, elastomers, ceramics, sands, composites, wood and biocompatible materials.

Desktop solutions span use cases across the product life cycle, from product development to mass production and aftermarket operations, and they address an array of industries, including automotive, healthcare and dental, consumer products, heavy industry, aerospace, machine design and research and development.

According to the company’s 10-K:

“At Desktop Metal, the belief is that additive manufacturing, commonly referred to as 3D printing, is one of the most exciting and transformational technology innovations of our time. According to the Wohlers Report 2021 and management estimates, the global additive manufacturing market, which includes spending on systems, materials, parts and other 3D printing software and services, is expected to grow from $13 billion in 2020 to more than $100 billion in 2030 at a compound annual growth rate of approximately 22%.”

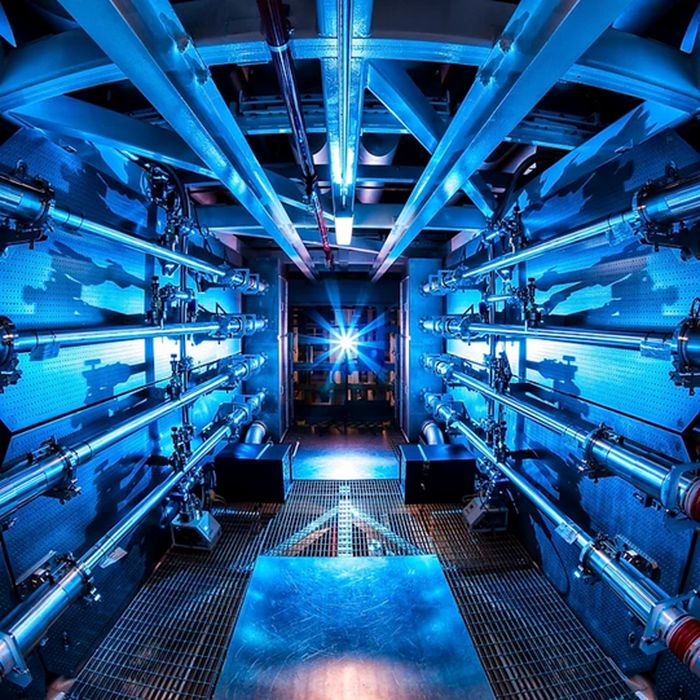

Seurat Technologies

Seurat Technologies has been getting a lot of attention recently. Not only has it raised a total of US$79.4M in funding with the last being a Series B, but it has filed about 51 patents with 47 currently registered.

Seurat has Porsche as an investor which should prove timely with the recent spin-out from Volkswagen and works closely with Siemens Energy. Seurat has commented on the benefits it anticipates from the recently enacted Infrastructure Act and the CHIPS Act.

The advantages of a concentration of businesses in an industry sector were described in one of our previous Fabbaloo articles.

Seurat is a contract manufacturer and unlike MarkForged and Desktop Metal, does not sell 3D printers. The company’s business model is focused on high-volume production, cost reduction and minimizing emissions.

The Cluster Advantage

A business technology cluster becomes attractive for suppliers, career planning, experienced talent and the advances that come from competition. The Boston region has many leading colleges and universities that emphasize 3D printing including MIT, Northeastern University, Worcester Polytechnic Institute and the Rhode Island School of Design.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Boston has become a metal 3D printing center of excellence. Mixing this expertise with the area’s leading universities is an excellent recipe for American innovation.