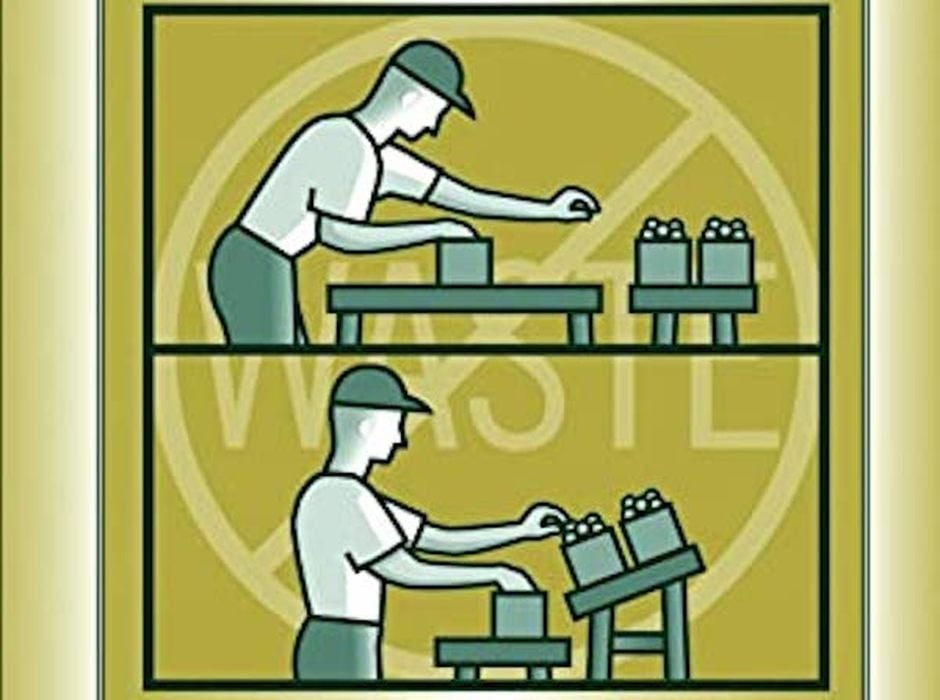

This week’s selection is “Identifying Waste on the Shopfloor”.

Waste on the shop floor? Isn’t that something we all can easily see: a pile of plastic scraps that require tidying up?

That’s not the waste we’re concerned with here. Instead we’re looking at the waste in the process of making things in the workshop, and in particular when using 3D printing.

For casual 3D printer operators this really isn’t a thing, but for those using their equipment for low volume production where the hours count, it is very important.

It might seem obvious that if wanting to print a quantity of parts you simply start the print jobs and come back later. But it’s not nearly that simple, as all manner of situations can occur that can delay obtaining the desired prints.

Machines can break, mistakes can be made, waiting for supplies can occur, and many other scenarios can cause delays in maximizing the utilization of the equipment.

The goal is to keep the machines working as much as technically possible to achieve the highest throughput possible.

The way to achieve that goal is to eliminate the “waste” in the process of making.

Some wastage is obvious, but there are many aspects that are less clear. This book details all common process problems that could result in throughput delays.

The book begins by defining “waste” in specific terms, and that it can occur in any of the common stages of the product lifecycle, including: manufacturing, conveyance, inspection, equipment, and management. They also define the benefits of eliminating waste, which not only includes quicker completion, but also higher throughput and lower per-unit costs.

The main section of the book defines what they describe as the “Seven Deadly Wastes”. These include:

- Overproduction

- Inventory

- Conveyance

- Defects

- Processing Waste

- Operation Waste

- Idle Time

The book describes several methods you can use to discover waste, and then more approaches for removing it. Even better, they describe methods for preventing waste right from the start.

If you’re considering launching a small production 3D print service, this is a book you should review beforehand to understand possible approaches for ensuring an efficient production operation. While some process inefficiencies might be obvious, some others are not.

We’re an Amazon Associate and earn a small fee from qualifying purchases. Help support our 3D print news service by checking out this book!

Via Amazon