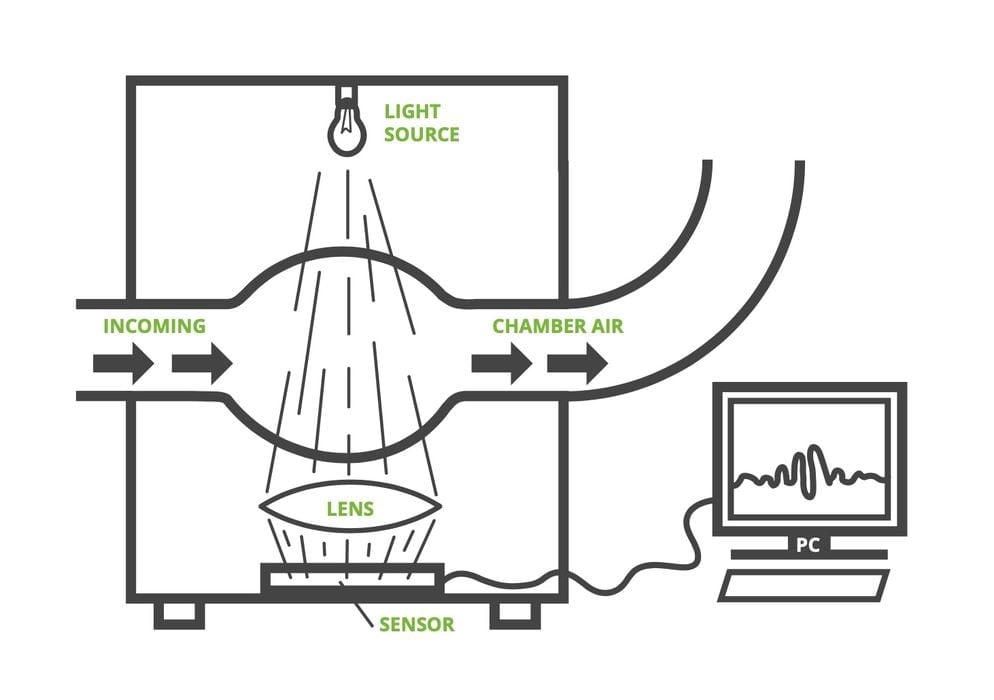

BOFA International published a paper analyzing the issues surrounding emissions from active 3D printers.

The company is one of the most well-known producers of fume extraction equipment, which is often used to capture noxious emissions from soldering stations, laser cutters, and 3D printers. They may have a slight conflict of interest here, but as you’ll see their material is still quite relevant.

For the two main 3D printing processes, FFF and vat polymerization (which includes SLA, MSLA, DLP, etc.), each emit a mixture of nanoparticles and volatile organic compounds (VOCs). While there are other hazards present in other 3D printing processes, such as DLMS or SLS, the BOFA paper covers only FFF and vat polymerization processes.

Fortunately, these are in fact the most commonly used 3D printing processes, and the paper explains that they represent 50% of the parts produced by the AM industry. I have a suspicion that’s a very conservative figure, as the number of FFF and VP machines vastly exceeds all others due to their low cost and wide availability. Many of these machines are not continuously operating, producing parts, and thus their “part count” total is lower. Nevertheless, their presence is exposed to far more people than the other processes.

The paper said:

“Both FFF and VP processes are most popular with entry level users of AM as they offer cost competitiveness, and access to a large variety of potential materials delivering high quality printed parts. However, due to their intended customer base, their design often requires frequent manual loading, handling and process optimisation, all of which occurs in very close proximity to the printing chamber, leading to a greater potential for exposure to airborne hazards.”

This is certainly true, and particularly so with resin equipment (VP), where poor handling practices can end badly with resin coating everything nearby.

The paper’s authors, Ross Stoneham MEng (Hons) IMechE and Joshua Evans MEng (Hons) IChemE, collected the results of multiple related studies and packaged it neatly together into a single paper explaining all aspects. It’s an ideal place to start understanding the emissions problem for anyone entering the space.

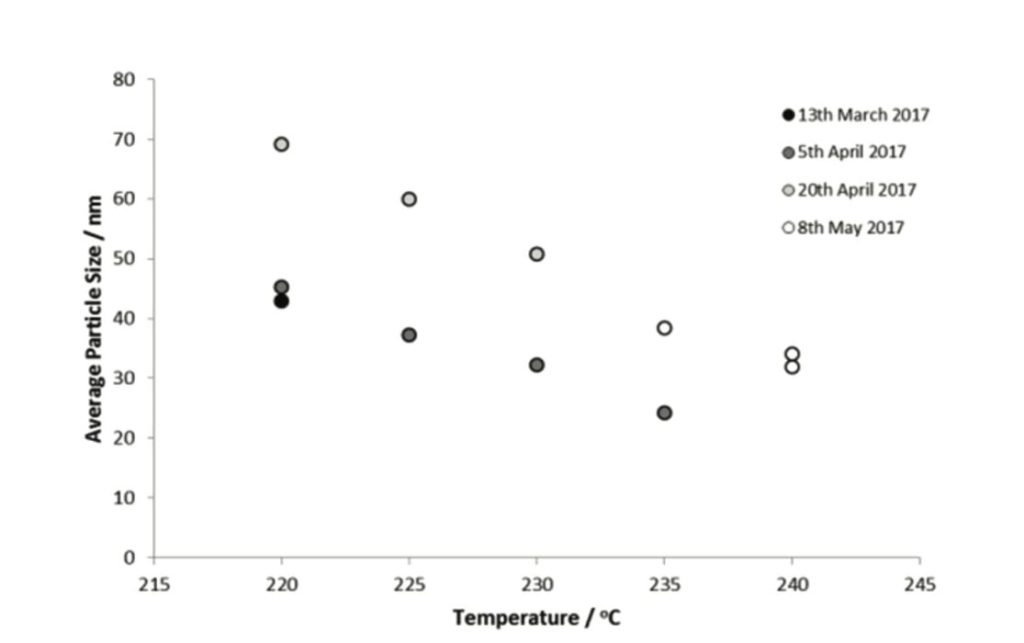

The paper explains the common methods of measuring both particulate and VOC emissions, and then displays previous findings. For example, it has been shown that the size of particles emitted from FFF processing tend to get smaller as the hot end temperature rises:

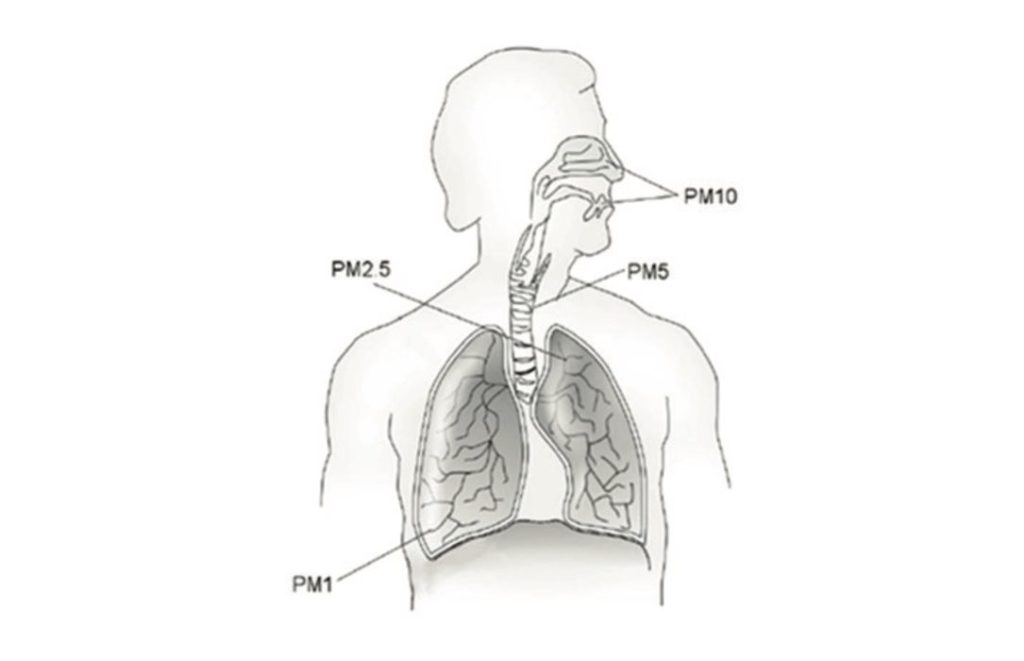

This is a particularly important finding, as small particles tend to be airborne for longer periods, and can be breathed in by nearby individuals. That exposes body tissues to the material for long periods, and that can be problematic.

Particle deposition in the respiratory system

(PM10 = 10 μm, PM5 = 5μm, PM2.5 = 2.5 μm and PM1 = 1μm) (Praznikar, 2012) [Source: BOFA International]

VP emission findings are also described and explained. Resins tend to off-gas material that is easily detected by the human nose, but these have been measured with some accuracy.

The paper also discusses other portions of the 3D print workflow, including post processing.

Perhaps the most important sections of the paper are where the results of these emissions are discussed. They explain how emissions can be absorbed through the lungs and what may happen.

The paper concludes with a discussion of workplace safety and regulations, focusing on the UK environment. However, similar regimes would be found in most countries, as everyone is affected by these emissions.

If you’re interested in finding out the basics of FFF and VP emission safety, I recommend reading this 18-page paper. Note: you’ll have to sign up to gain access to the paper, but it’s certainly worth doing so.