Researchers have developed a new algorithm that could light up the 3D printed fashion industry.

3D printing and other automated manufacturing systems are able to produce customized products, even at volumes as low as “one”. This is quite unlike today’s mass manufacturing industries, where millions of identical products are produced.

Mass manufacturing approaches the problem of differently-sized people requiring differently-sized clothing in a brute force method: create several standard sizes and produce many units. We’ve all become accustomed to shopping for clothing in that way, mainly because there aren’t widely accessible alternatives.

But automated manufacturing could theoretically pose a solution: these making machines, including 3D printers, could produce items of clothing that are perfectly fitted to the wearer. If such a capability were widely available, it would surely be the most desired option over the “maybe it will fit” approach of mass manufacturing.

Alas, there’s a big problem: measurement.

In order to generate 3D models or designs for a custom job, software will have to be fed precise dimensions to tweak template designs. Where do these measurements come from?

You’d think the answer would be from a 3D body scanner. These are devices that have been available for some years now, and they claim to capture the 3D shape of a person in some precision.

Could these 3D body scans be used to manufacture clothing?

It turns out no, according to a new paper entitled, “A method for increasing 3D body scanning’s precision: Gryphon and consecutive scanning” by researchers at Loughborough University and Manchester University.

They are perhaps the only researchers yet to investigate this area, and they found that essentially zero percent of 3D body scans are appropriate. Specifically, they say they do not meet the ISO 20685:2010 standard.

Hold on, what’s ISO 20685:2010? It’s an international standard for “3-D scanning methodologies for internationally compatible anthropometric databases”. It describes everything one needs to know about anthropometric data, with “anthropometric” meaning measurements of the human body as they relate to 3D scanning.

But how hard can this be? Are not the dimensions of a body a pretty discrete number? The numbers may be, but it’s how they are measured that is the question. For example, if you are measuring a waistline, where, exactly, is that to be measured on a body? When you think about it, there are plenty of vague measurements that we commonly use, and these would be of little value to any automated system because of that vagueness.

The ISO standard attempts to clarify all that. It also provided the researchers a “measuring stick” to gauge the value of current 3D scanning measurement techniques. They found that virtually everything fails miserably.

This means that a machine to make clothing could not work, because the measurements should be at least as accurate as those collected using manual techniques.

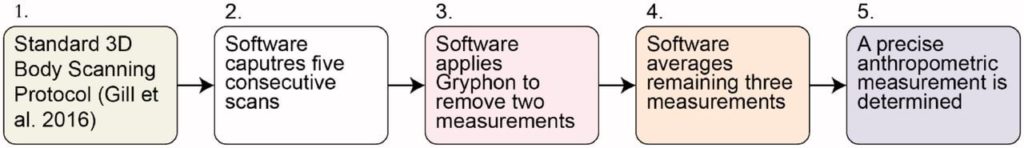

The researchers found that the typical 3D scanning workflow creates multiple points of potential error. They explain:

“Sources of error in the body scanning process could occur from capture devices, point cloud rendering, avatar development, automated measurement based on an algorithm, position, and the scan participant’s posture.”

To overcome these challenges, the researchers developed their own measurement algorithm, “Gryphon”, which is significantly more accurate:

”Our Gryphon process builds on this, recognising the body scanner’s uniqueness and seeks to define an approach to meeting ANSUR’s precision; mindful of ANSUR’s development, existing manual measurement techniques, and their sources of error. Gryphon further allows all scans to be subject to precision cheques. Manual methods do not provide precision cheques with the same volume and depth of data, rigorously checking each measurement.”

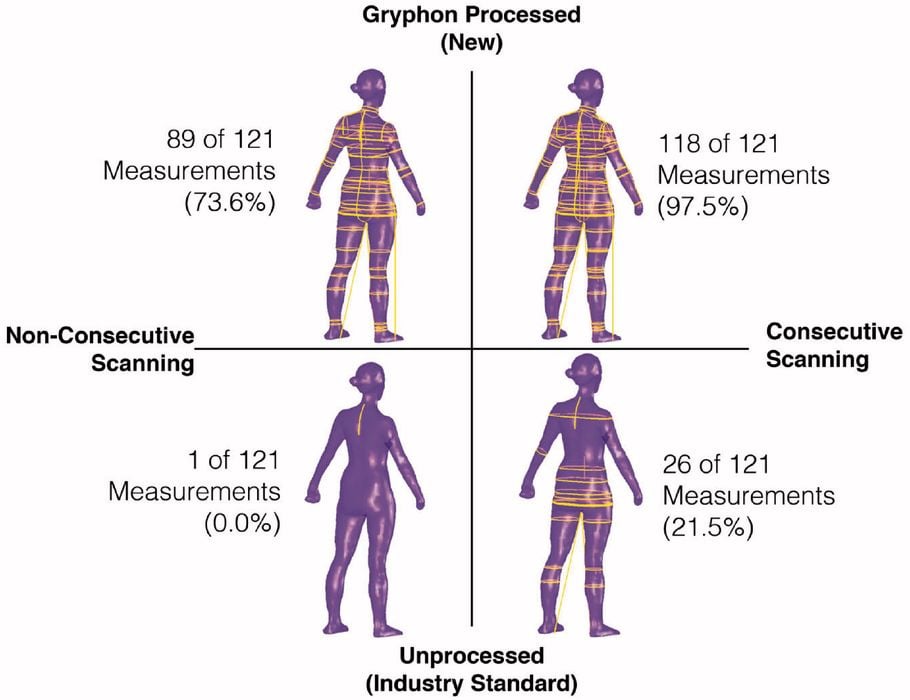

In the end, they say Gryphon is 353% more reliable than standard consecutive scanning approaches, and an astonishing 12,088% more reliable than non-consecutive scanning methods.

They say this transforms “faith” in body scanners to “trust”, and that could make a big difference for industry.

Up to now we haven’t seen body scanners used widely to prepare custom measurements for personalized clothing, and that’s likely because it simply wouldn’t work. But now with Gryphon, perhaps it can.

This work proves beyond a doubt that it is possible for 3D scanning to produce usable body measurements for clothing production.