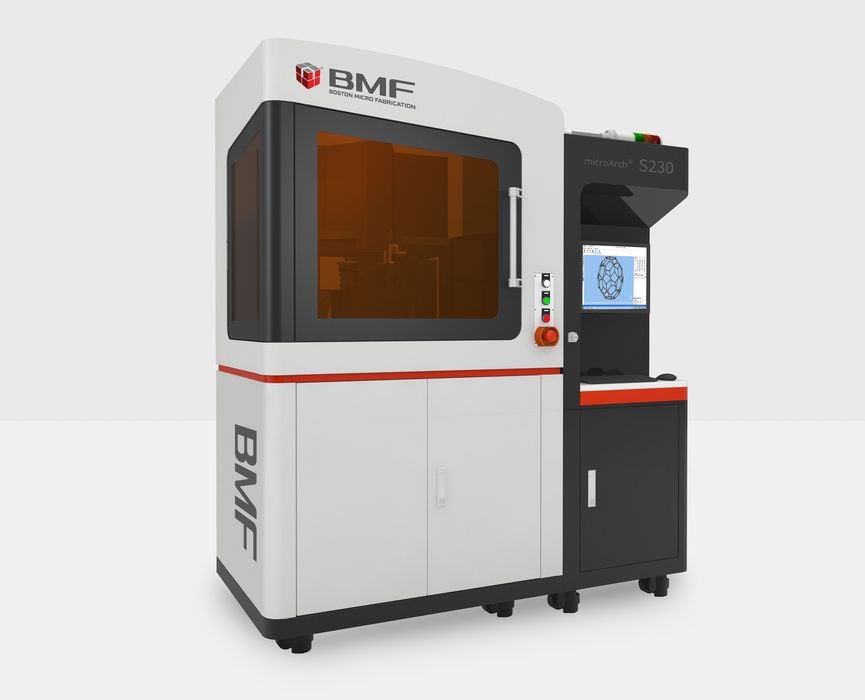

BMF announced a new microArch 3D printer, the S230.

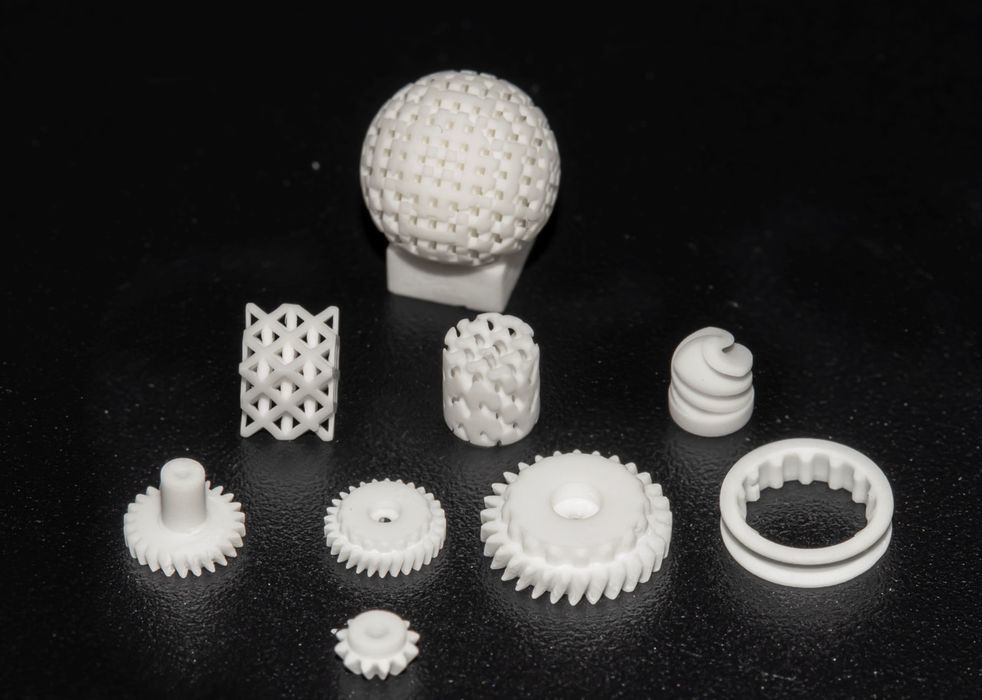

The Boston-based company develops 3D printers with extreme resolution. Their current line of equipment, for example, offers a resolution of up to an incredibly tiny 2μm (that’s 0.002mm).

With resolution that fine, it is possible to build all types of small mechanical parts for an increasing variety of industries. This image shows the scale we’re describing here:

Their “PµSL” 3D printing process involves “flashing” a layer with an extremely fine array of UV pixel light that proceeds layer-by-layer to build an entire object.

The new S230 machine carries on this capability, but offers additional benefits. First, there is a larger build volume of 50 x 50 x 50 mm.

Now I know what you are thinking: that seems pretty small for a 3D printer build volume. It may be, if compared to typical devices. However, remember that the S230 is printing parts with very fine resolution. It’s goal is to 3D print small mechanical parts with near-perfect accuracy, not to produce large, coarsely formed objects.

The S230 also can print up to five times faster than previous models, making it much more suitable for production applications. The faster you can print, the more throughput can be generated by a machine.

BMF explains more changes in the S230:

“Additional key features of the microArch S230 include active layer leveling, automated laser calibration and the capacity to handle higher molecular weight materials with viscosities of up to 20,000 Cp, resulting in the production of stronger functional parts.”

The company simultaneously announced the availability of three new materials for the S230:

- AL (Alumina) Ceramic – A biocompatible and chemical-resistant ceramic resin meant for high temperature, high strength and high stiffness applications such as tooling (injection molding), casing and housings and medical devices.

- HT 200 – A durable, high-temperature and high-strength resin that can be soldered, and designed for end-use in electrical connectors and electrical components.

- MT (Magnesium Titanate) Ceramic – The combination of high dielectric constant and low dielectric loss make MT Ceramic suitable for millimeter wave applications such as antennas, wave guides and other electronic components.

These materials hint at the possible applications for BMF technology: critical industrial parts. Importantly, these parts can be produced with complex geometries, as designers can take advantage of 3D printing possibilities.

There is a large and growing market for such capabilities, as part designers are gradually recognizing they can beat competitors by designing unique parts with unusual geometries.

That transformation of design has already happened in several industries. Now, with BMF’s help, it may also happen in the small parts market.

Via BMF