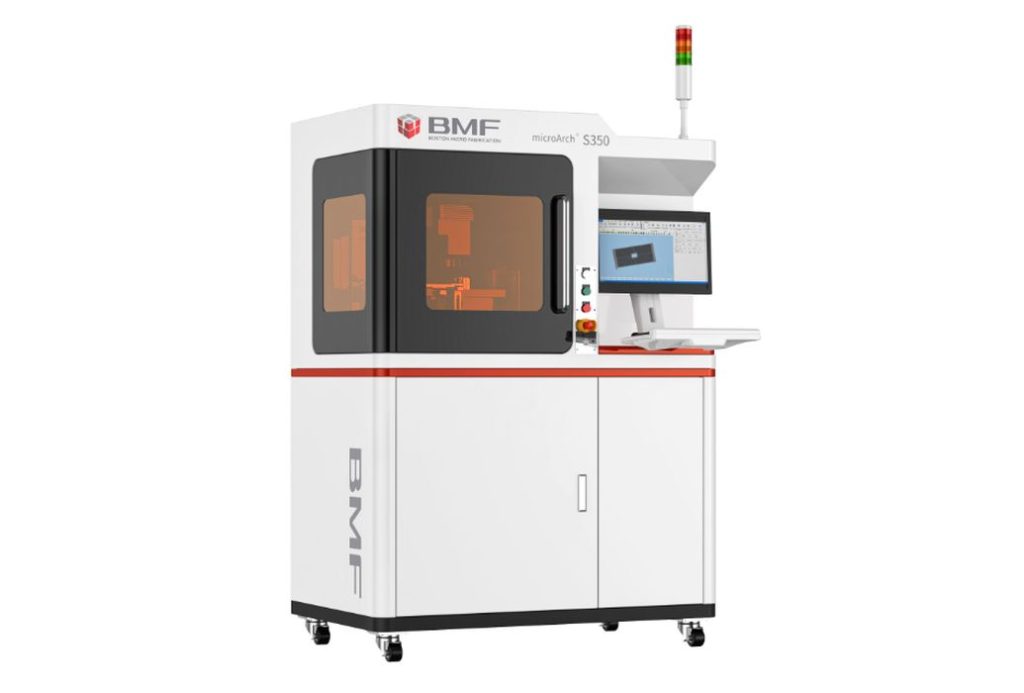

Boston Micro Fabrication (BMF) announced a new 3D printer, the microArch S350.

BMF specializes in 3D printers with extreme resolution, suitable for production of parts with extremely fine features. Their most recent device was the microArch S240, which uses their “PμSL”, for “Projection Micro-Stereolithography” resin process to achieve very fine resolutions, up to 0.002mm.

You can read a bit more about PμSL in our look at the microArch S240.

BMF offers three different lines of micro 3D printers based on maximum resolution: 0.025mm, 0.010mm and the extremely fine 0.002mm, of which the microArch S240 belongs.

The new device, the microArch S350, belongs to the 0.025mm resolution line, and it offers a large build volume of 100 x 100 x 50 mm. That may sound small as compared to conventional desktop 3D printers, but in fact when you’re printing at such high resolution the parts are typically small and would fit within this build volume.

The build volume of the S350 is in fact the largest offered by BMF in their 0.0025mm line.

But it’s not just about the build volume. BMF explains:

“With a larger build volume (100 x 100 x 50mm) and fewer projection zones to improve print speed, the printer can be used in the production environment or labs to print both micro-scale parts with high-resolution features or small parts requiring high accuracy or precision.”

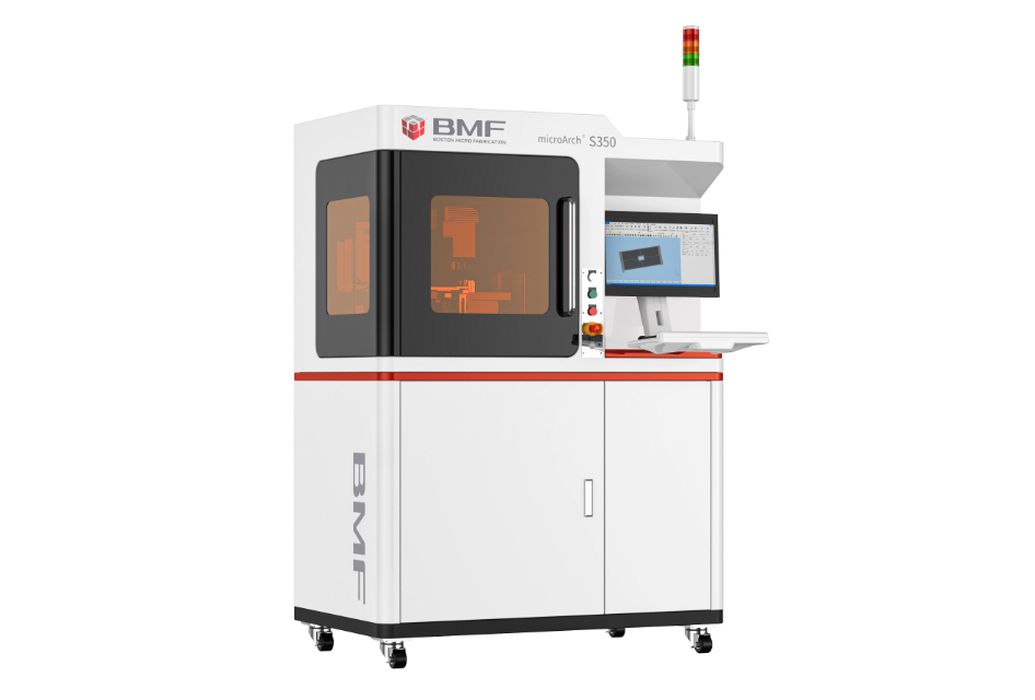

They’ve also re-designed the part removal process by including an “automated lateral membrane shift” that is said to simplify part removal. In addition, this feature is able to integrate with robotic systems to enable fully automated additive production.

There are also several other new features that all point towards efficient production:

- Automated resin top-up process

- Laser displacement sensor to ensure quality

- High-speed roller for resin deposition

BMF also announced two new resins that are compatible with the S350, including a high-temperature bio-compatible material, “BMF MED”, and a fire-retardant material from Loctite.

BMF CEO John Kawola was quite excited about the new machine, saying:

“BMF has become the industry leader for printing small and micro-sized parts requiring high resolution, accuracy and precision in the 2µm and 10µm resolution spaces. Now, we’re bringing that experience to an even wider range of end-use applications at the 25µm level. While this printer is geared more toward industrial customers that need faster throughput, greater volume, and more automation, the result is still best-in-class part quality compared to other DLP platforms and we cannot wait to see what our customers accomplish with it.”

It seems that BMF has moved strongly into the production space for micro prints. However, the company’s sales growth will depend on adoption of the technology by those requiring small but detailed parts. It may be that the best applications for this technology have not yet been invented, and BMF may have to help companies understand what is possible with this new equipment.

Via BMF

Please send me the price information about the printers and resin materials. I need to know the reflective index, hardness, bonding strength to ceramic substrates or cavities.