BigRep published an interesting piece explaining how they break down the features in “smart 3D printing”.

The term “Smart” is fascinating, because it is a relative term. As such, it is often abused by marketers describing their new equipment as “smart”. But what does that actually mean? For example, does the inclusion of a 64-bit controller board mean the device is “smart”? Would it still be smart if it didn’t have sophisticated software leveraging that processing power?

Because of that, I’ve always been a bit suspicious of vendors proclaiming their latest product as “smart”. I like to see results: what does that “smartness” actually do for you?

That’s a good start, but then there are an infinite number of possibilities. Is the fact that a machine records the list of jobs printed make it “smart”? How about dynamically adjusting the thermoplastic flow to match thermal conditions? Is that also “smart”? Is it “smarter” than recording job activity? And so on.

BigRep is one of many 3D printer manufacturers concerned about this, and it’s not just out of technical curiosity. There’s an important reason for understanding what “smart” actually means.

This is because today’s 3D printers are increasingly being used for end-use part manufacturing. While in the past most 3D printers produced prototypes due to lousy materials, that’s all changed now and manufacturers are using the devices to make their products.

These products are made at scale. From low-volume production to larger-scale operations, additive manufacturing is now a thing.

But that implies the 3D printers involved must integrate with existing manufacturing systems, which have been refined and digitized over the past decades. It’s not good to drop a 3D printer into the middle of a factory and hope it works. It has to work with the existing highly refined workflows that make that factory efficient, in both the making and quality control steps.

To do so a 3D printer has to provide quite a bit of data to the overall production process.

Early 3D printers didn’t do any of this; they were essentially standalone machines requiring an operator to do everything manually, including tracking activity.

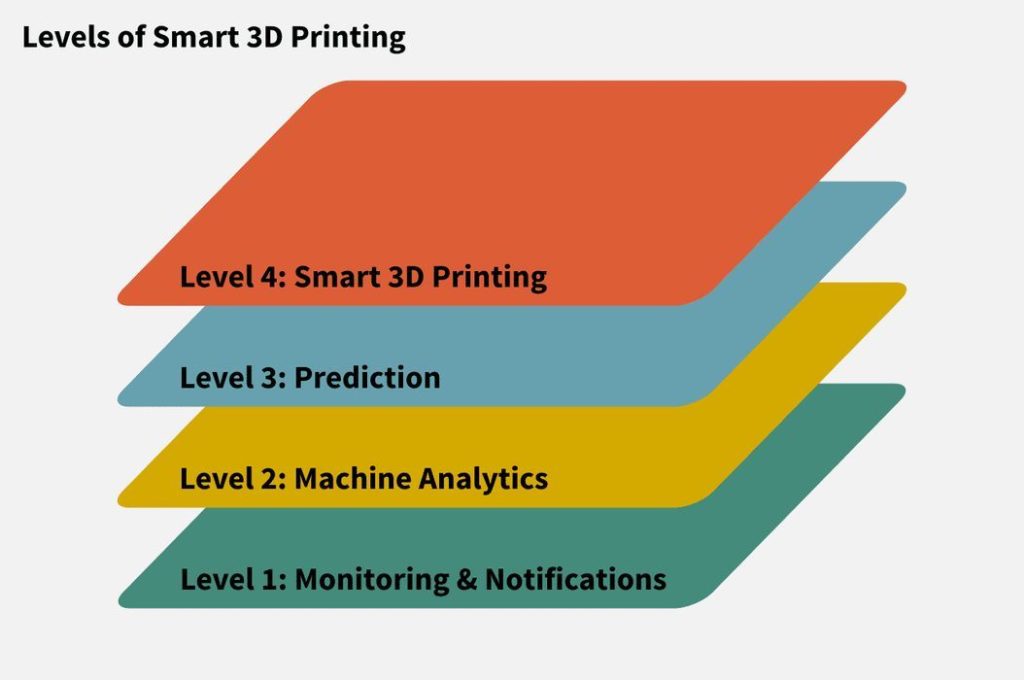

The possibilities for data participation in a larger process are endless, but BigRep described a way to categorize them in a very sensible way. The concept involves four levels of “smart 3D printing”. Let’s take a look at each one.

Level 1: Monitoring & Notifications

The first layer is “Monitoring & Notifications”. This is exactly what it appears to be: as jobs start and stop, the machine sends notifications to the designated authorities. It’s also possible to examine the current state of the machine, including the current job’s progress.

This is a very simple “smart” configuration and is actually available on many inexpensive 3D printers.

Level 2: Machine Analytics

The second level involves cross-job data, where data is collected and analyzed to understand capacity, reliability and more based on a series of jobs over time. This can be quite important for operating a bank of 3D printers, where some may exhibit behavior different from other units, suggesting repairs are required.

It’s also possible to record sensor data as the print job progresses to match it against prior runs to detect variations. However, this is just a detection step, not a corrective step.

Level 3: Prediction

Prediction involves leveraging the data collected and attempting to predict the part outcome. BigRep explains:

“When you know the indicators of optimized print parts and the combination of settings, material etc., you will be able to predict the quality of a print part in advance, without the need for print iterations. You will get the first print right.”

This can even involve predicting when machine service might be required.

Level 4: Smart 3D Printing

This final level involves using the collected machine data in real time to adjust operations. For example, if a deviation from the expected is observed, the machine might be able to take corrective action during the print job to recover the work.

This is an enormous boost to quality and reliability, as long-running jobs would fail far less often. This saves not only material from waste, but also valuable machine time.

Conclusion

BigRep’s concept layers are understandable and applicable to every 3D printer when you examine their specifications. It would be possible to “grade” a machine by placing it among the four describe levels, providing much more perspective on the intelligence of a given device.

What is “smart” then? If you don’t know, then make a ruler to measure it with, and that is what BigRep has done here. Please have a read through their interesting story.

Via BigRep