You can now use BigRep FLOW to quickly create tooling for factories with no CAD experience.

This new cloud-based service from BigRep could be very significant, as it could open up many more sales and service for the Berlin-based company.

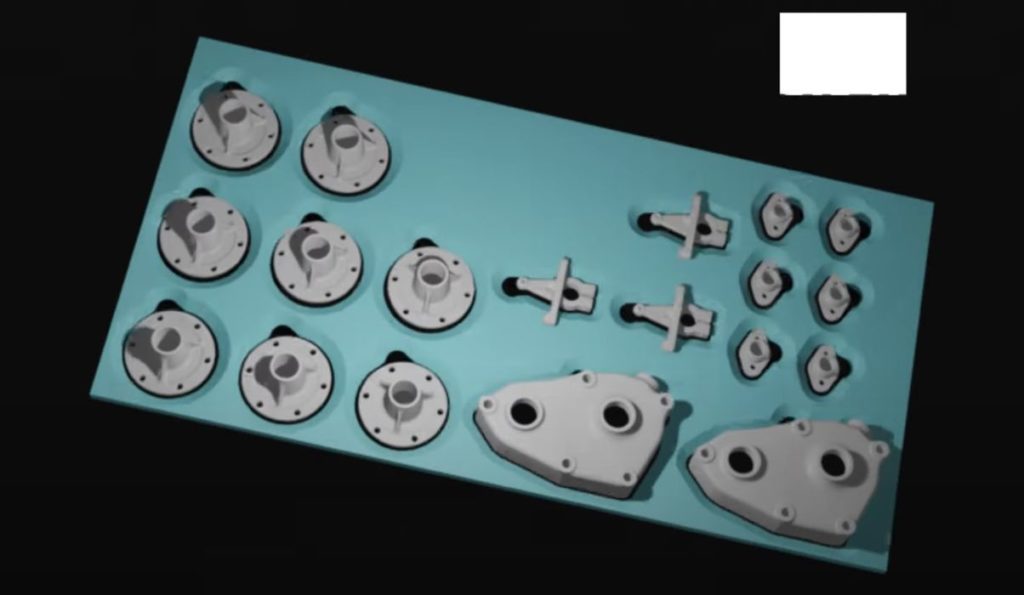

The problem they’re getting at here is the use of tools in factories. These are custom devices produced to aid factory operations by arranging parts in particular ways expected by the factory operations flow. For example, a robot might expect to find input parts oriented in a specific way, laid out in a 4 x 8 array.

Well, that’s easy, you might think: just 3D print a container to hold the parts in that way.

That is easy to say if you happen to have the CAD training and software to quickly design such an object. But most times the folks on the factory floor don’t have those skills. If they did, they’d be in another building designing parts!

BigRep believes they have the answer in BigRep flow, a cloud-based service that bypasses the need for CAD knowledge entirely to generate this type of tooling.

It’s surprisingly easy to use: the operator uploads either the CAD model or scan of a part. BigRep FLOW then applies it to a selection of pre-made 3D models that can be dynamically adjusted by the operator.

For example, in this scene the part is “subtracted” from the base tooling to create a precise space to hold the part. The operator can then specify how many of these are required and in what orientation. It looks very easy to use.

When satisfied with the design, it can be sent directly for 3D printing on a handy BigRep 3D printer. But if there isn’t one present, it can be sent to a remote 3D print service to make the part. BigRep experts will also certify the designs to be correct before proceeding with printing.

BigRep’s massive 3D printers are also ideal for this application, as factory tooling often exceeds the size of typical 3D printers. BigRep has found a way to leverage their large format.

This is the kind of 3D print generator that could gain a great deal of use, as it would make factory operations more efficient.

For BigRep, this could be a big deal. One of the barriers holding back 3D printing is a lack of CAD skills, and BigRep FLOW completely eliminates that need. From what I’ve seen, it would seem that any factory worker could very easily use BigRep FLOW to quickly create the necessary tooling for an operation.

BigRep is smart to include a print service with BigRep FLOW, as it allows an interested client to try it without significant investment. But if it proves worthy they may eventually buy their own BigRep 3D printer to enable on-site production of tooling.

I’m thinking that BigRep FLOW will be a very popular tool for many factories.

Via BigRep