While we spend much time contemplating the hardware of 3D printing, the software is just as important.

That’s the case today with an announcement from UpNano, makers of the NanoOne, a device that can micro print 3D objects. How “micro” is this device? Let’s just say that the minimum wall thickness is 170nm. That’s “nm”, meaning 0.00017mm, vastly smaller than typical 3D printers.

This is accomplished by the use of a two-photon process (“2PP”) in which resin is cured by a certain frequency of light. Unlike common MSLA devices that use an LED/LCD panel, or SLA devices that use laser, 2PP is quite different.

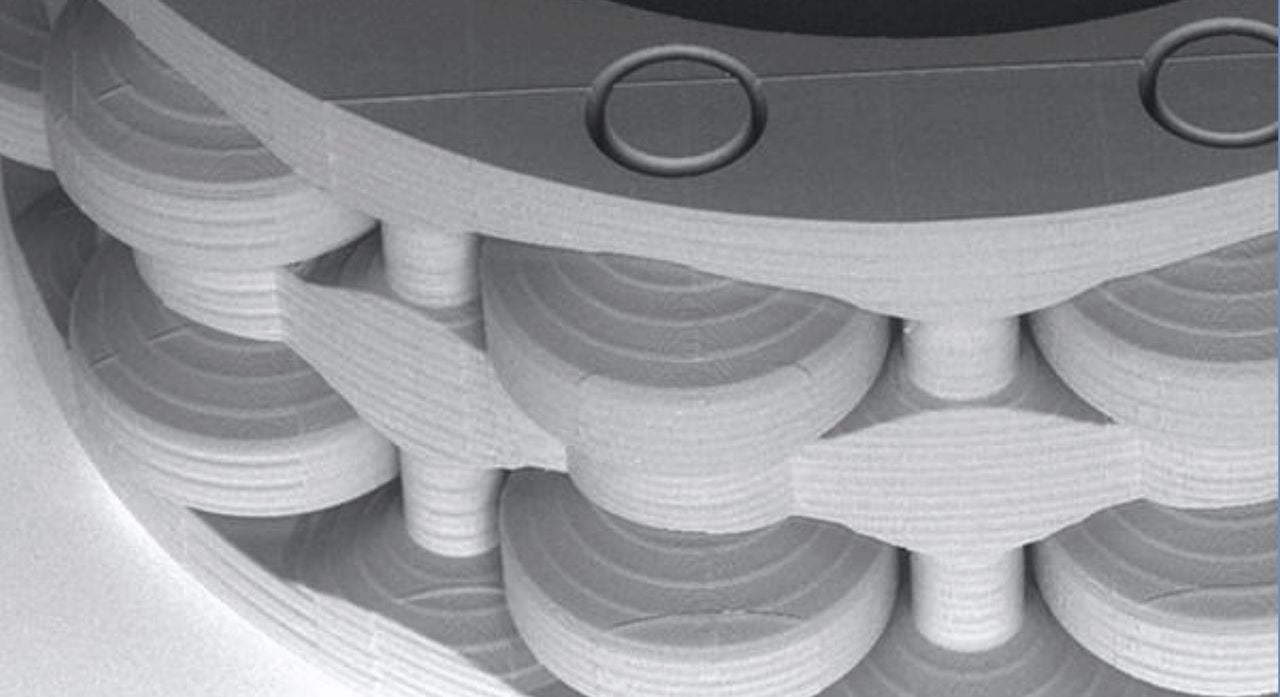

In 2PP printing a transparent vat of photopolymer resin is traversed by a focused beam of light. The beam is optically set up so that the light focuses on a single point in 3D space, where sufficient photons are delivered to trigger solidification. This focal point is moved around to build the tiny object.

To run the NanoOne, UpNano provides software to prepare 3D print jobs, as one might expect. Due to the unusual technology of this device, you can’t use open source slicing tools like PrusaSlicer or Ultimaker Cura.

Recently UpNano released a new version of their software that has quite a few improvements. UpNano explains:

“Now smart stitching can improve the quality of the final product and the already high printing speed can be increased even more. Also, using the same objective and material, several completely different print jobs can be combined into one, saving costs and further time. All this is greatly simplified by an intuitive user interface that is an integral part of all software developed by UpNano. The upgrade is compatible with all NanoOne printers and most existing customers have acquired it already.”

One issue addressed by the new software is the production of seams. Seams are challenging to produce because of the requirement to move the optical field of view during a print job, and require a “stitch” to combine printed portions together.

UpNano co-founder and COO Denise Hirner said:

“Now, products with exactly defined seams can be printed. The unique features of our latest upgrade help to reduce this. By addressing more parameters individually and dynamically, it is now possible to define the exact positions of stitching lines. Depending on the final structure, this allows for a smart integration of the seams into the design.”

While this will be of considerable interest to UpNano 3D printer operators, there is a message to everyone: the 3D printer software is just as important as the 3D printer.

Via UpNano