We haven’t written about BeeHex for quite some time, but it turns out they’ve been developing an unusual food 3D printing technology involving plastics.

We first encountered BeeHex in 2016, when they emerged as a startup looking to build a Pizza 3D printer. The idea was that food manufacturers could produce far more consistent frozen pizzas or stadium operators could more rapidly produce pizzas when using robots instead of manual labor. It was a decent idea, and they even received some investment to pursue the concept, and had relocated to Columbus, OH.

I hadn’t heard much from the company until this week. It turns out that Columbus is the home for a large number of major bakery operations, and it seems that BeeHex pivoted towards that market instead of pizzas.

They now sell a series of bakery equipment models, which are essentially food 3D printers that can decorate cakes, cookies, cupcakes, etc.

What’s new is that at CES last week they revealed they’ve been working on a space-based food 3D printing system to feed future astronauts. The concept sounds similar to 3D printed pills, which enable personalized pills containing the exact dosages required each day. Here, however, it would be the food items that are personally designed and 3D printed.

One more very interesting reveal was that apparently they’ve also been looking on a way to transform scrap plastic into food! According to a report on Interesting Engineering, the idea is to shred certain waste plastic and combine it with “specifically engineered bacteria”, which would break down the plastic in a bioreactor. The resulting goop could be used to form a wide variety of food products using 3D printing technology similar to what BeeHex is using today.

BeeHex CEO and co-founder Anjan Contractor said:

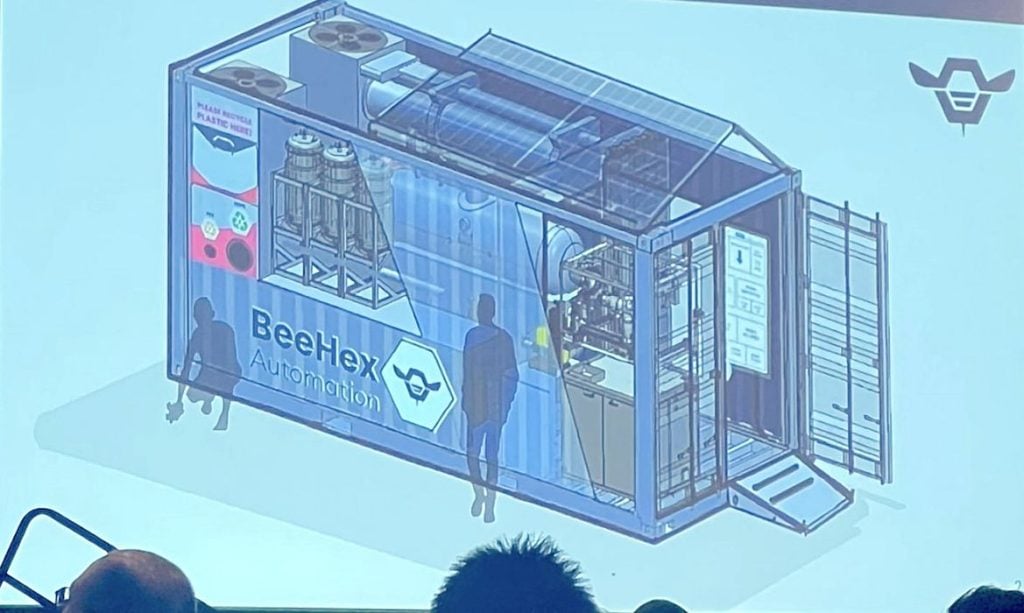

“What you see over here is a shipping container… we have completely changed that. On one side, plastic waste is collected, which will be shredded. It will eventually move into the bioreactor, which contains very specific engineered bacteria. So if you want to create steak out of plastic, the entire mechanism on one side of this container will be able to produce steak out of plastic- or chicken breasts.”

This is an incredible development, and one that could change 3D printing in general.

As every 3D printer operator knows, there will be enormous amounts of polymer waste produced from 3D print activities. Failed prints, discarded designs, and support material are all waste, and it accumulates. There are few, if any feasible ways to recycle this plastic junk.

The notion of being able to not only recycle waste polymer, but transform it into food seems quite appealing. However, there were no specifics stated by BeeHex, and it’s likely this process will be many years before it is realized and applied to other fields.

But that’s how space spin offs work: invest in space, reap the rewards later.

Meanwhile, I am looking forward to seeing food samples from this new process.

Via BeeHex and Interesting Engineering