Axtra3D unveiled its Hybrid PhotoSynthesis (HPS) technology and Lumia printer, which the company believes will revolutionize 3D printing.

3D printing has come a long way since stereolithography (SLA) hit the scene in the ’80s. While innovative technologies have emerged since then, such as digital light processing (DLP) and liquid crystal display (LCD), the past decade has seen only advances in existing technologies. Italian startup Axtra3D is posed to change that with its revolutionary new technology, Hybrid PhotoSynthesis (HPS), which it unveiled at Formnext 2021.

“We’ve been quietly developing HPS for a long time,” said Gianni Zitelli, Axtra3D CEO. “We truly believe HPS has the power to transform 3D printing, and our experience at Formnext confirms that this technology is an industry game changer.”

The technology company’s goal has been to develop advanced solutions using optoelectronics. Knowing that end users were forced to choose between SLA, DLP or LCD, the Axtra3D team set out to create a technology that would combine the benefits of all three processes into one machine instead of having to sacrifice surface quality or print area for speed and resolution. According to the company, its HPS technology offers fine resolution, large print area, excellent surface quality and high speed, along with continuous printing and isotropic part performance.

“In our HPS technology, the laser defines the resolution and, as a result, HPS offers higher resolution and fine feature reproducibility than a standard DLP,” Zitelli said.

The patented technology combines the best of both worlds. It uses a superior laser while possessing projector capabilities for every cross-section and layer. This synchronized light engine ensures that the high resolution of SLA is matched with the needed resolution.

“HPS brilliantly coalesces the energy from two light sources, DLP and laser, creating a harmonized light engine that efficiently harnesses the power from the two sources,” said Praveen Tummula, Axtra3D chief operations, business officer and cofounder. “Users often have high surface finish costs, but with the fine surface quality and resolution offered by HPS, they can save time and money as the 3D printed parts don’t require any post-print surface finishing.”

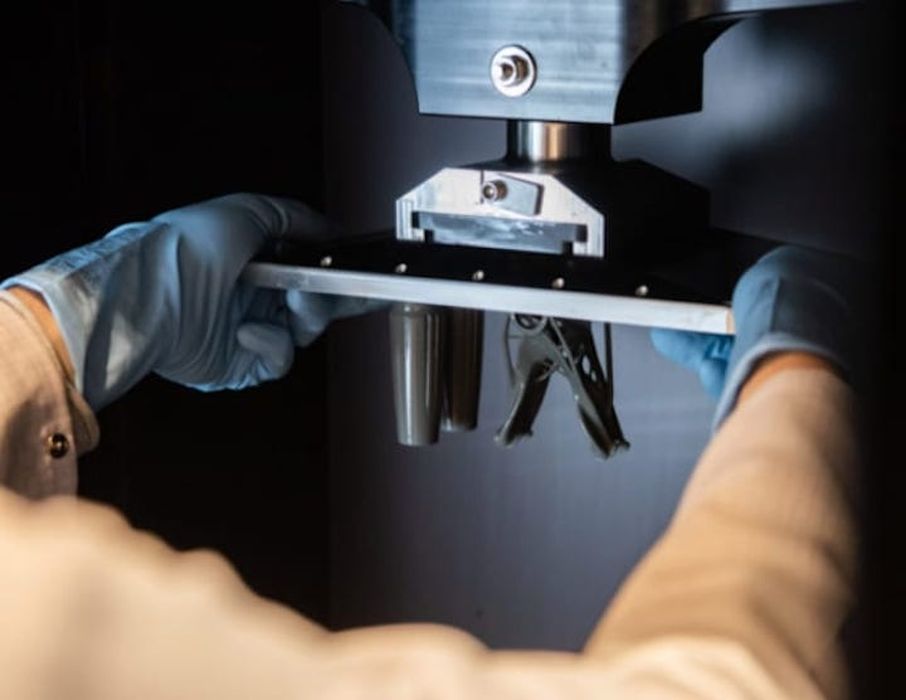

The team at Axtra3D proved its level of expertise by developing the HPS technology and then set its sights on creating a printer to harness the technology’s power. Crafted with nearly every industry in mind—from prototyping to dental to aerospace and manufacturing—the Lumia printer enables parts to be cured by the projector while the laser cures the edges.

The Lumia has a print speed of 18 cm per hour on the Z-axis, up to 9 mm/minute (or) 0.35 in/minute. The entire volume can be printed in 90 minutes, though print speeds vary depending on layer thickness and materials used. The machine’s build volume is 265 mm/10.4 in, X; 150 mm/5.9 in, Y; and 600 mm/23.6 in, Z, with a 24-liter total volume. It also incorporates Axtra3D’s other patented technologies, including Fast and Easy Peeling Technology, Zero Suction Effect Technology and Non-Degenerative Vat Membrane Technology.

Read more at ENGINEERING.com