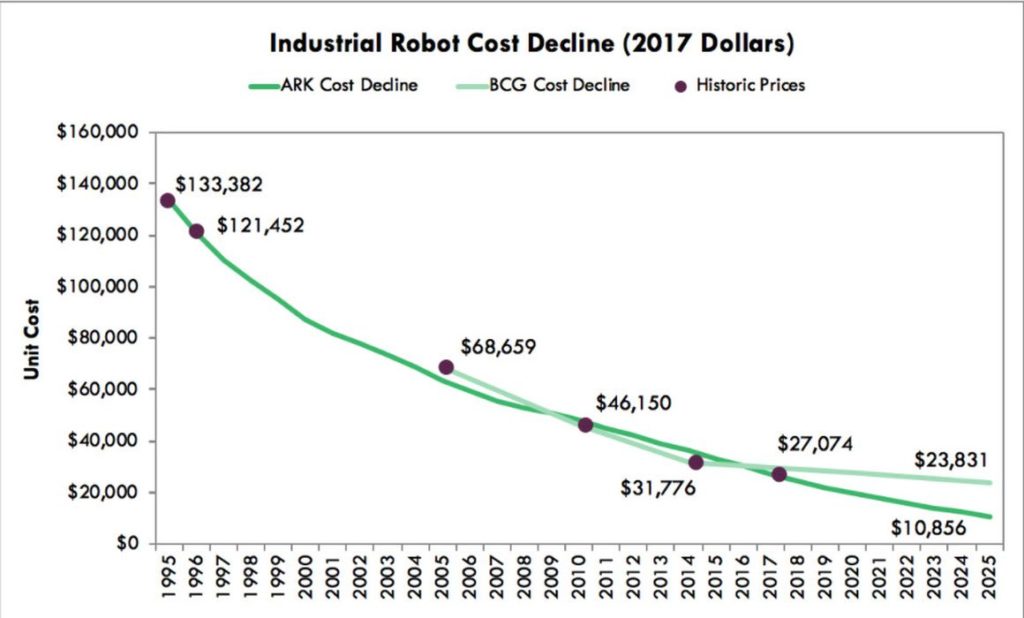

Technical advances and the decreasing cost of automation are offsetting the advantages of offshoring.

Onshoring is the practice of locating a business operation in the country where its goods or services are offered. To those unencumbered by advanced economic theory, this may seem like a sensible idea. However, in the 1980s, when regulatory burdens and high labor costs began to bite into profit margins, the great thinkers of the time began moving manufacturing facilities to lower-cost jurisdictions such as India, Malaysia, Vietnam, and China.

Forty years later, with protectionist tariffs in place and global labor and fuel costs rising, the decisions to expose supply lines to long sea journeys, hurricanes, political unrest, and global pandemics appear to have been shortsighted. In exchange for temporary relief for their bottom lines, past business leaders have ended up introducing enormous complexity and risk into their supply chains, as well as significantly damaging the environment.

Complex supply chains are responsible for 90 percent of industry’s impact on our environment, and today only 13 percent of the world’s oceans remain undamaged by humans. Companies that are serious about reducing risk and limiting their operations’ impact on our global habitat need to address the Gordian knot our supply lines have become. Fortunately, we did not ship our innovators overseas as well.

Traditionally, companies have implemented automation solutions to reduce costs, increase output and improve quality. Changes in personal buying behavior, chronic labor shortages, and supply chain disruptions have changed the equation for many businesses. These new pain points brought into focus by the global pandemic are also forcing companies to question how they can reduce risk and meet their production requirements at home.

Advances In Robotics Are Making Automation More Widely Available

The cost reductions of automation, global labor cost increases, and the fear of supply chain disruptions are now offsetting the benefits of offshoring. In 2021, sales of robots destined for non-automotive users outpaced the automotive sector for the first time. Despite the pandemic, year over year orders in life sciences, food, consumer goods and plastics increased dramatically.

The introduction of cobots (collaborative robots) in 2008 by Universal Robots has, in the company’s words, “democratized automation.” Universal Robots defines the cobot as “Robots that enable different people in different countries working in different industries to automate different processes with different budgets and programming skills.”

Typical uses for cobots include tasks that would be dangerous or repetitive for humans, such as CNC machining, circuit board assembly, metal fabrication, injection molding, packaging, line loading/unloading, testing and inspection. Small companies, many with fewer than 20 employees and no experience with robotics, are losing their fear of technology and finding ways to employ these machines to meet increasing demand while retaining their existing workforce.

Additive Manufacturing Is Bringing Supply Chains Closer to the Customer

The ability to translate digital data into tangible objects quickly and with precision is changing the way businesses operate on multiple levels. The flexibility that 3D printing provides in implementing new designs or changing old ones can result in huge savings on logistics, warehousing and labor.

One 3D printer can replace an entire machine shop as well as many of the personnel required to run equipment. A component that required several different machining processes using traditional manufacturing techniques can now be stored digitally and produced as needed with minimal human interaction.

Additive manufacturing is also changing the way we look at automation. In 2019, ABB Robotics took additive manufacturing to a new level when it incorporated 3D printing capabilities into its RobotStudio software. Adding a free-form robotic arm to the print process brings much more than just speed and agility to traditional printing operations.

Read more at ENGINEERING.com