During an Autodesk University session, experts demonstrated the benefits of generative design to perform part consolidation and optimize designs.

Additive manufacturing has changed manufacturing forever. Among its many benefits is the ability to optimize designs through part consolidation. Luke Ice and Alexander Jones, engineers at Johnson & Johnson 3D Printing Center of Excellence, conducted a class during Autodesk University 2021 to discuss this design method and demonstrate generative design with Autodesk Fusion 360.

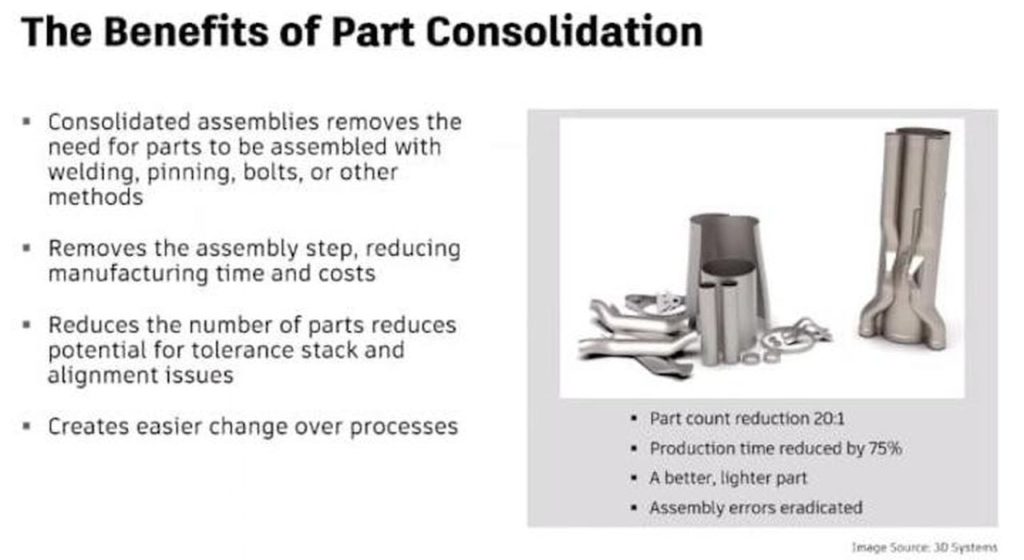

What is part consolidation? At the basic level, instead of creating the different parts of a multipiece assembly and assembling them, additive manufacturing allows for those parts to be created during printing for a finished and complete part requiring no assembly. When time and money are top concerns, this is a beneficial solution that also allows for more complex designs. The ability to reduce parts also means preventing tolerance stack or alignment issues, ensuring a precisely printed part and enhancing changeover processes.

Jones provided an example of how part consolidation is beneficial. In this case, the final assembled part required 20 parts. By using part consolidation, production time was reduced by 75 percent. The part was also much more lightweight and required no assembly.

Another benefit is reducing SKUs and having to keep spare parts on hand. For the above example, all those 20 parts required their own SKU. After part consolidation, it was just one part with one SKU, with no extra space required to store parts. That part also had more structural integrity. Printing one fully assembled part means not having to worry about a faulty bolt or bad weld affecting the final product.

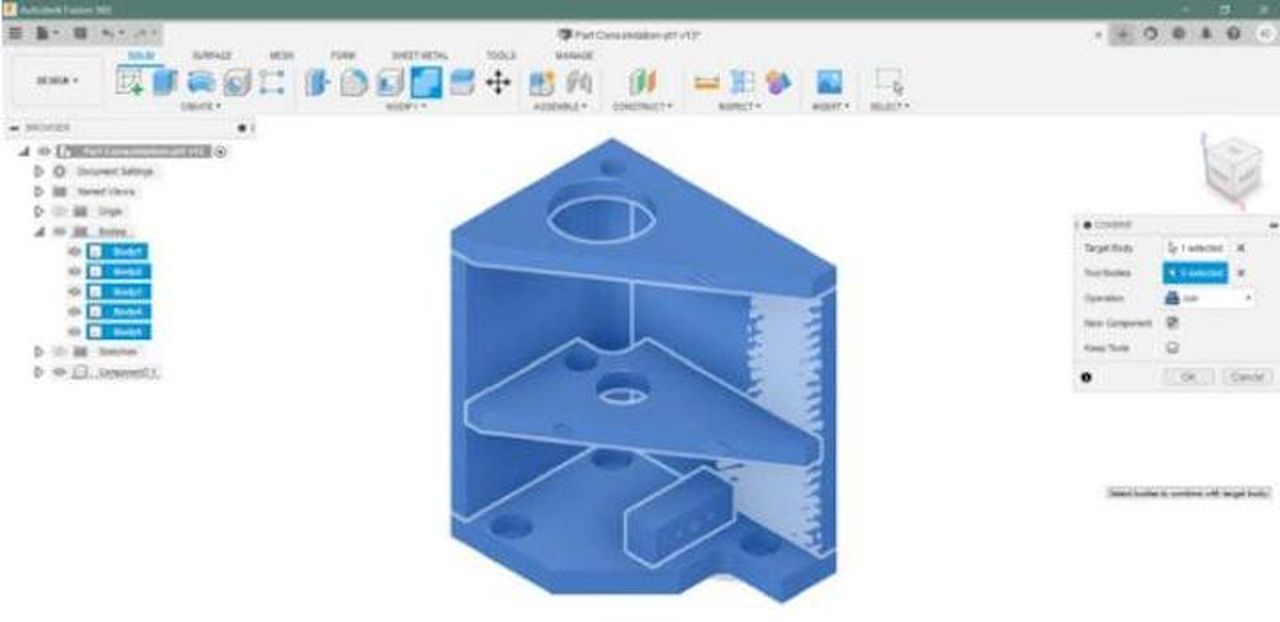

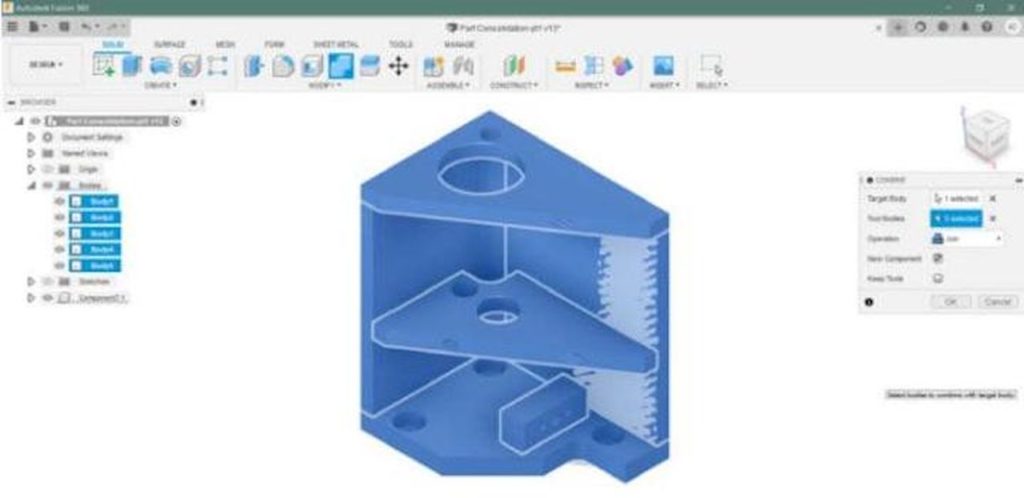

Ice then took over the discussion to walk attendees through the process of part consolidation. The example he used was a bracket. Its purpose is to hold the lasers and mirrors used for eye surgery using a robotic arm. This delicate part is only about 3.5 inches in height. Initially, it was created with six pieces of machined aluminum, which were mechanically fastened together.

Read more at ENGINEERING.com