Autodesk announced during its recent Advanced Manufacturing Summit that some of its powerhouse manufacturing tools would be added to Fusion 360, including PowerMill, PowerShape and PowerInspect.

Back in 2014, Autodesk acquired Delcam and its suite of manufacturing products. While PowerMill, PowerShape and PowerInspect have been available through Autodesk since then, the solutions have all been living in their own ecosystems.

By wrapping these software products into Fusion 360, Autodesk is aiming to continue its push to make Fusion a hub for everything from design to manufacturing. Many Delcam product customers have long been concerned about when the software products might be incorporated into Fusion 360. These customers have been worried about functionality or license changes caused by the solutions’ incorporation into a different product.

According to Autodesk, putting PowerMill, PowerShape and PowerInspect under the Fusion 360 umbrella will provide a seamless interface between the products, as well as deliver the capabilities at a lower price point.

“In most cases subscribers will receive access to a broader range of functionality at a lower price,” noted Autodesk . The presentations from Autodesk assured that current subscribers to PowerMill, PowerShape and PowerInspect would not see a difference in the performance of the software, but would rather experience integration into the world of Fusion 360.

In the announcement blog, Autodesk said, “Come September 14, if you are an existing PowerMill, PowerShape, and/or PowerInspect subscriber, your account will update to one of four new offerings specifically geared toward your needs. The four new subscriptions include Fusion 360 with PowerMill Standard, Fusion 360 with PowerMill Ultimate, Fusion 360 with PowerShape, and Fusion 360 with PowerInspect.”

New Workflows

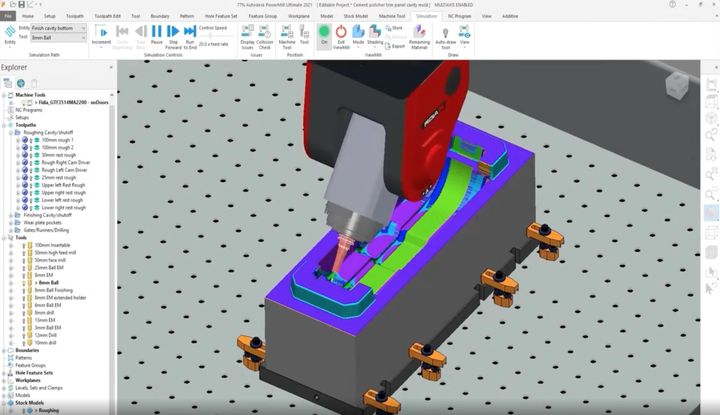

The addition of these software products to the world of Fusion 360 means that new workflows are bound to emerge. A perfect example is the access to AnyCAD, which provides software agnostic CAD data, so you can collaborate with your colleagues who are using SOLIDWORKS and tie that back to creating CAM with PowerMill.

According to Autodesk, this means that “constraint-based sketching, intuitive 3D parametric modeling, and generative design technology will let you create parts, fixtures, and tooling for your PowerMill projects. You’ll also have access to mechanical and thermal simulation in Fusion 360 to verify designs and validate material selections prior to manufacturing, reducing the cost of prototyping.”

To that same end, you can perform simulation studies of models from PowerShape, which is a modeling companion to PowerMill that is used for molds, tools and complex parts, within Fusion 360. And Fusion will offer CAD support for PowerInspect users to perform collision checking, and so on, to produce reports for final project approval.

Read more at ENGINEERING.com